- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How the digital transformation of PCBA factories can improve competitiveness

2025-05-30

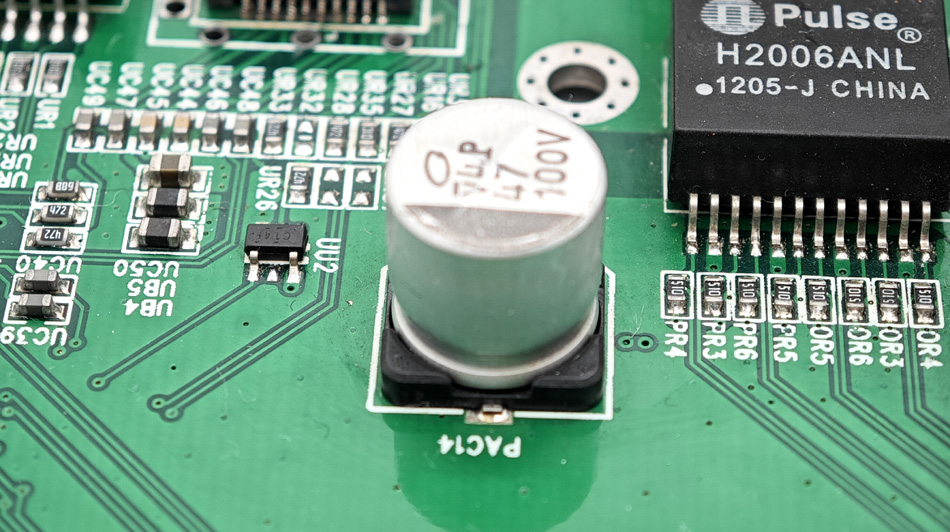

Against the backdrop of increasingly fierce competition in the global manufacturing industry, the PCBA(Printed Circuit Board Assembly) processing industry is also facing multiple pressures such as cost, quality, and delivery time. In order to remain competitive in the market, PCBA factories must undergo digital transformation. By introducing advanced digital technologies, factories can optimize production processes, improve production efficiency, and improve product quality, ultimately standing out in the fierce market competition. This article will explore how PCBA factories can improve their competitiveness through digital transformation.

1. Digital optimization of production processes

Digital transformation provides PCBA factories with the opportunity to optimize production processes. By using automated equipment and intelligent production lines, factories can significantly improve production efficiency and reduce manual intervention. The use of advanced digital technologies, such as the Industrial Internet of Things (IIoT) and automated production systems, can monitor various indicators in the production process in real time, such as equipment operating status, temperature, humidity, etc., to ensure the stability and efficiency of the production process.

In addition, digital technology can also optimize production scheduling and process control, predict production bottlenecks through big data analysis and make adjustments in advance, avoiding waste and delays in the production process. This not only improves production efficiency, but also better meets customer delivery requirements.

2. Improve quality management and traceability

Digital transformation has also greatly enhanced the quality management capabilities of PCBA factories. By implementing a full-process digital traceability system, the factory can fully trace each batch of products, from raw material procurement to production and manufacturing, to product testing and delivery, and the data of all links can be accurately recorded. This provides strong support for quality control.

For example, by introducing automated inspection technologies (such as AOI, X-ray inspection, etc.) and intelligent quality control systems, PCBA factories can detect potential quality problems in real time during the production process and make timely adjustments. This highly automated and precise quality management significantly reduces the defect rate in production and ensures high-quality delivery of products.

3. Improve supply chain transparency and response speed

In PCBA processing, the complexity of supply chain management often affects delivery time and cost. Digital transformation makes supply chain management more transparent and efficient. With advanced supply chain management systems (such as ERP, MES, etc.), PCBA factories can track suppliers' inventory, transportation status and order progress in real time, so as to better predict and arrange production needs.

At the same time, digital technology can also optimize procurement processes and reduce the risk of interruptions in the supply chain. For example, factories can predict raw material demand through data analysis, make purchasing decisions in advance, and avoid production delays caused by material shortages. More efficient supply chain management can effectively improve the response speed of PCBA factories, thereby providing customers with faster delivery services.

4. Enhance customer interaction and customization service capabilities

With the growing market demand for personalized customization, PCBA factories are also facing the challenge of providing more flexible and rapid responses to customer needs. Digital transformation enables factories to maintain real-time communication with customers through online platforms, understand customers' latest needs and product specifications, and quickly adjust production plans. This instant feedback mechanism not only improves customer satisfaction, but also enhances the factory's agile response to market changes.

In addition, by adopting digital design tools (such as CAD, CAM, etc.) and virtual prototyping technology, PCBA factories can provide customized services to customers in a shorter time, quickly verify design solutions, and shorten product development cycles. This not only helps meet customers' personalized needs, but also brings higher profit margins to factories.

5. Data-driven decision-making and continuous optimization

Digital transformation enables PCBA factories to drive decisions through data analysis to ensure continuous optimization of each link. Through big data and artificial intelligence (AI) technology, factories can conduct in-depth analysis of production data, quality data, and market data to identify potential opportunities for improvement. Based on these data analyses, factories can formulate more reasonable production strategies, optimize process flows, and improve overall operational efficiency.

In addition, data analysis can also help factories identify hidden costs in production, reduce waste through refined management, and further improve cost-effectiveness. Through continuous data optimization, PCBA factories can continuously improve their core competitiveness and maintain their market leadership.

Summary

The digital transformation of PCBA factories is not only a technological update, but also a comprehensive strategic choice to enhance competitiveness. From optimizing production processes, improving quality management, strengthening supply chain management, to enhancing customer interaction and data-driven decision-making, digital transformation provides PCBA factories with many competitive advantages. In the face of increasingly fierce market competition, digital transformation is undoubtedly an indispensable part of the future development of the PCBA processing industry.

-

Delivery Service

-

Payment Options