- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How PCBA factories achieve excellent manufacturing through continuous improvement

2025-05-27

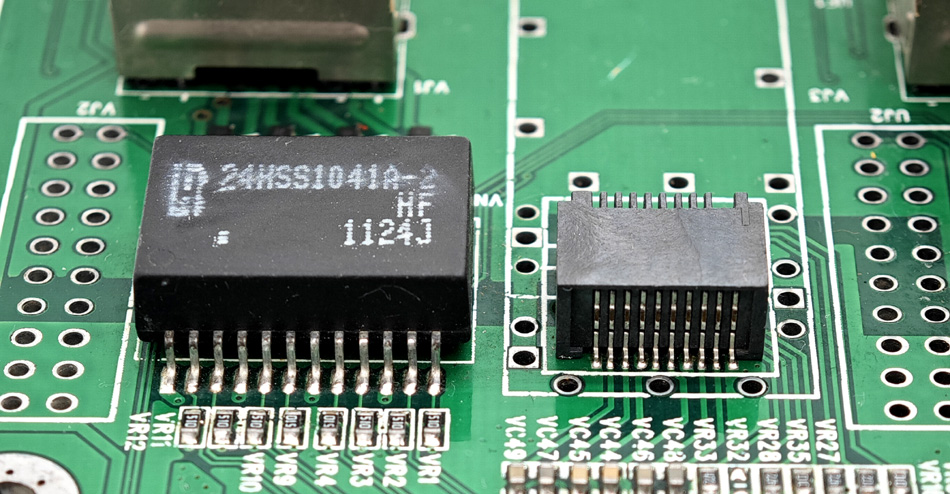

In the fierce market competition, PCBA factories must continuously optimize their production processes, improve product quality, shorten delivery cycles, and reduce production costs. Continuous improvement is the key to achieving excellent manufacturing. It not only involves technological innovation, but also process optimization, personnel training, and the improvement of management systems. This article will explore how PCBA factories can achieve excellent manufacturing through continuous improvement and stand out from the competition.

1. Introducing lean production to improve production efficiency

Lean production is the core of continuous improvement. It aims to improve overall production capacity by eliminating waste, improving efficiency, and reducing production cycles. In PCBA processing, factories can optimize production line layout and reduce material handling and waiting time through lean production methods. By analyzing each production link, PCBA factories can identify bottlenecks and optimize them to ensure the smoothness of the production line.

For example, factories can reduce the idle time of the placement machine and the time to readjust the equipment by optimizing the SMT (surface mount technology) process, thereby improving the utilization rate of the equipment. Adopt a precise production scheduling system to ensure that production tasks can be completed on time, according to quality, and according to quantity, thereby improving overall production efficiency.

2. Implement a quality management system to ensure product quality

One of the core elements of manufacturing excellence is to ensure high-quality products. To this end, PCBA factories need to implement a sound quality management system (such as ISO 9001) to strictly control quality at every stage from raw material procurement to production. In the production process, by introducing automated inspection equipment such as automatic optical inspection (AOI) and X-ray inspection technology, defects can be discovered in the shortest time and corrected in a timely manner.

In addition, the factory should establish a sound quality traceability system to track each batch of products throughout the process to ensure that the quality of each link meets the standards. By continuously analyzing quality data, the factory can identify common quality problems and formulate targeted improvement measures.

3. Employee training and skills improvement

Employees are the core force to promote continuous improvement and achieve manufacturing excellence. PCBA factories should conduct regular employee training to improve their skills so that they can operate advanced equipment proficiently and promptly discover and solve problems in the production process. In addition, the factory can also motivate employees to continue learning and improving through skill competitions and reward mechanisms, thereby improving overall production capacity.

The training content is not limited to operating skills, but also includes knowledge in quality control, equipment maintenance, environmental awareness, etc. By comprehensively improving the quality of employees, the factory can continuously promote continuous improvement in an atmosphere of full participation.

4. Strengthen equipment management and maintenance

Equipment is an important asset in the production process of PCBA factories. Continuous improvement also requires strengthening the management and maintenance of equipment to ensure the stability and efficiency of equipment during the production process. Through regular equipment maintenance, fault prediction and repair, the factory can effectively avoid production stagnation caused by equipment failure.

In addition, PCBA factories can introduce digital equipment management systems to monitor equipment status in real time through data collection and analysis, timely discover potential failure risks, and perform preventive maintenance. This practice can not only extend the life of the equipment, but also ensure efficient production.

5. Data-driven decision-making optimizes production processes

In modern PCBA processing, the application of big data and artificial intelligence (AI) technology provides factories with huge room for improvement. By collecting and analyzing production data, factories can monitor the production process in real time and find potential optimization points. For example, through data analysis, factories can optimize the process parameters of the production line, adjust the equipment operation status, and improve the efficiency of each link in the production process.

In addition, data-driven decisions can also help factories predict demand changes in advance and avoid inventory backlogs or shortages. Through accurate data analysis, factories can respond more flexibly to changes in market demand and quickly adjust production plans while ensuring quality.

6. Establishment of a culture of continuous improvement

Achieving excellent manufacturing not only relies on the improvement of technology and processes, but also requires the establishment of a corporate culture of continuous improvement. In PCBA factories, every employee should participate in the improvement process and put forward innovative ideas and suggestions. Through regular employee feedback meetings, improvement discussions and other forms, factories can brainstorm and find the direction and path of improvement.

Factories should encourage employees to ask questions, challenge existing working methods, and promote positive interactions between management and operations. By establishing an open and inclusive cultural atmosphere, factories can continue to promote improvements and ensure that products and services always maintain high quality.

Summary

Continuous improvement is the key to achieving excellent manufacturing in PCBA factories. Through lean production, quality management, employee training, equipment maintenance, data-driven decision-making and cultural construction, factories can continuously optimize production processes, improve product quality, and reduce costs. In the increasingly competitive global market environment, PCBA factories can only maintain their advantages in the industry by continuously promoting continuous improvement.

-

Delivery Service

-

Payment Options