- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does the project management of PCBA factories ensure the achievement of production goals?

2025-05-26

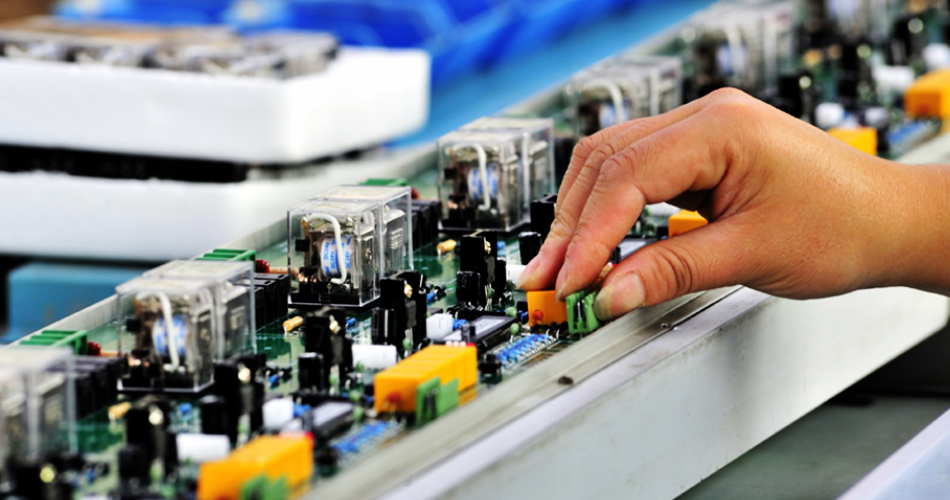

In PCBA processing, the smooth realization of production goals is crucial to ensuring customer needs and improving corporate competitiveness. And effective project management methods are the key to ensuring that these goals are completed on time and efficiently. PCBA factories achieve production goals by implementing systematic project management, coordinating production processes, and optimizing resource allocation. This article will explore in depth the project management strategy in PCBA processing to help understand how it ensures the stability and efficiency of production.

1. Set clear production goals

In the start-up phase of the PCBA processing project, clear production goals are the basis of project management. Production goals usually include specific requirements in terms of product quality, production cycle, cost control, etc. PCBA factories need to ensure the implementation of various requirements through scientific planning.

Define goals: PCBA processing factories need to set quantifiable production indicators based on customer needs, such as part defect rate, production cycle, material loss, etc., to ensure that the goals are specific and executable.

Decompose goals: Decompose large goals into small goals for each production stage to facilitate tracking and management, thereby improving the achievement rate.

Clear goal definition and decomposition help the project team understand the direction of the project, thus providing strong support for subsequent production.

2. Strict production schedule management

PCBA processing projects usually have a relatively strict delivery cycle, so schedule management is an important part of project management. Project managers need to ensure that each link in the production process is completed on time through schedule planning, schedule tracking, schedule adjustment and other means.

Make a detailed schedule: According to production goals and production capacity, reasonably allocate time and make a detailed production schedule.

Real-time monitoring and adjustment: During the PCBA processing process, managers need to monitor production progress in real time and adjust the plan in time when deviations occur to ensure that the final delivery date is not affected.

Through effective schedule management, PCBA factories can better control the production rhythm and prevent project delays.

3. Resource optimization and cost control

An important responsibility of project management is to ensure that the utilization of resources in the PCBA processing process is maximized while reducing production costs as much as possible. Project managers should coordinate various aspects such as raw materials, equipment, and human resources to ensure the smooth progress of the project.

Reasonable arrangement of resources: Allocate manpower and equipment according to production needs to avoid idle or overloaded resources.

Cost control measures: Control costs by optimizing procurement processes, reducing waste generation, etc., to achieve a balance between production efficiency and economic benefits.

Effective resource management can not only improve the overall efficiency of PCBA processing, but also increase the factory's profit margin.

4. Quality management ensures production compliance

Quality management is one of the core contents of PCBA processing project management. Only through a strict quality management system can PCBA factories ensure that product quality meets customer needs during the production process and enhance the factory's market competitiveness.

Establish a quality management process: PCBA factories usually implement a total quality management (TQM) system, formulate detailed testing and control processes, and conduct all-round quality monitoring from raw material inspection to finished product delivery.

Quality monitoring and improvement: Monitor product quality during the production process at any time through online testing, factory inspection, etc., and feedback the test results to the production line to ensure that problems are rectified immediately.

Through comprehensive quality management, PCBA factories can ensure that each batch of products meets customer quality requirements.

5. Communication and coordination: Ensure team collaboration

In the project management of PCBA processing, cross-departmental communication and coordination are one of the key factors to ensure the smooth implementation of the project. Project managers need to maintain efficient communication with R&D, procurement, production, quality and other departments to ensure transparent flow of information.

Regular project meetings: hold project meetings regularly to ensure that all departments understand the project progress and solve existing problems in a timely manner.

Information sharing platform: establish an information sharing platform to update production progress and problems in a timely manner to help project team members to collaborate effectively.

Good communication and coordination can improve the team's response speed and collaboration efficiency, making the project progress smoother.

Conclusion

In the project management of PCBA processing, by setting clear production goals, strict progress management, resource optimization and cost control, quality management and effective communication and coordination, the factory can achieve production goals more efficiently and meet customer needs. In the future, with the continuous advancement of management tools and technologies, the project management capabilities of PCBA factories will be further improved, injecting new vitality into the development of the industry.

-

Delivery Service

-

Payment Options