- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Operation optimization of PCBA factories: from cost control to efficiency improvement

2025-05-24

In the highly competitive field of electronic manufacturing, PCBA factories must take effective operation optimization measures to control costs and improve efficiency to enhance market competitiveness. Through lean management, process optimization, intelligent technology and employee training, PCBA processing companies can reduce operating costs and improve production efficiency, ensuring that they provide customers with more competitive products and services. This article will explore the key strategies of PCBA factories in operation optimization.

1. Lean management: eliminate waste and reduce costs

Lean management is the core method of cost control in PCBA processing, which aims to improve resource utilization by eliminating waste in production. PCBA factories can achieve lean management through the following means:

Reduce raw material waste: optimize material procurement and inventory management to ensure on-demand procurement and reduce backlogs. Through an accurate material management system, the factory can track the use of each batch of materials, thereby reducing waste generation.

Optimize production processes: By improving the layout and process of the production line, reduce the ineffective movement of materials and personnel, and improve production efficiency. The use of methods such as Kanban management can achieve continuous flow of the production line and avoid waiting time.

Through continuous lean improvement, PCBA factories can maintain the stability of production quality while reducing costs.

2. Automation and intelligence: improving production efficiency

Automation and intelligent technology are important means to improve PCBA processing efficiency. In the production process, the use of advanced automation equipment and intelligent systems can greatly improve the production capacity of the factory:

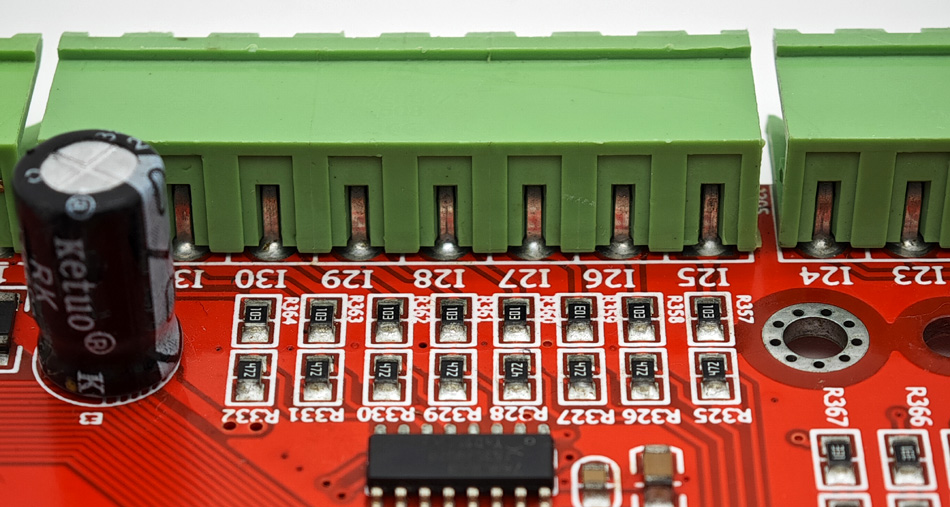

Automated production equipment: The introduction of automatic placement machines, automatic welding equipment and other automated equipment in PCBA processing can significantly increase production speed and reduce the instability caused by manual operation.

Intelligent management system: The use of intelligent systems such as MES (manufacturing execution system) and ERP (enterprise resource planning) can monitor the production process in real time, optimize production scheduling, and improve equipment utilization. Such systems can also help factories better manage production resources and improve overall operational efficiency.

Through the application of automation and intelligence, PCBA factories can not only improve production efficiency, but also reduce equipment failures and downtime, and further optimize costs.

3. Process optimization: shorten production cycle and increase delivery speed

In PCBA processing, optimizing production processes is an important step to improve operational efficiency. Process optimization can help factories shorten production cycles and meet customers' demand for delivery speed:

Simplify production processes: By analyzing the necessity of each process, removing redundant processes, and achieving streamlined production. Factories can remove non-value-added steps to shorten the entire production process.

Cross-departmental collaboration: By strengthening communication between the production department and logistics, procurement, quality management and other departments, an efficient collaborative process can be formed to ensure that each batch of orders is completed smoothly and delays are reduced.

Process optimization can also reduce uncertainty within the order cycle, making production plans more predictable and stable.

4. Employee training: Improve skills and reduce operational errors

Employees are an important resource in PCBA processing, and improving employee skills is one of the keys to achieving operational optimization. Through regular training, factories can improve employees' operating levels and reduce errors and rework in production:

Equipment operation training: Ensure that operators are proficient in the use of automated equipment to avoid downtime and capacity loss due to operational errors.

Quality control training: Strengthen employees' quality awareness so that they can find and solve potential problems in production and improve product qualification rates.

Continuous employee training can also improve employee work enthusiasm and reduce turnover, thereby reducing the cost of recruiting and training new employees.

5. Quality management: reduce rework costs and improve product consistency

In PCBA processing, quality management is not only related to customer satisfaction, but also directly affects the operating costs of the factory. High-quality products mean less rework and scrap, thereby reducing costs. Through a complete quality management system, PCBA factories can ensure product consistency:

Introducing automatic inspection equipment: Using equipment such as automatic optical inspection (AOI), it can quickly detect defects in products and prevent unqualified products from entering the next process.

Establish a quality traceability system: Trace the data of each step in the production process to ensure that problems can be located and handled in time, and reduce defects from the source.

Through effective quality management, PCBA factories can improve product consistency, reduce resource waste caused by rework, and further improve operational efficiency.

Summary

The operation optimization of PCBA factories needs to start from multiple aspects, including lean management, automation technology, process optimization, employee training and quality management. Through these measures, the factory can significantly reduce operating costs, improve production efficiency, and gain greater advantages in the fierce market competition. Continuous optimization of operations can not only enhance the profitability of the factory, but also provide customers with high-quality products and fast delivery experience, making the PCBA factory invincible in the market.

-

Delivery Service

-

Payment Options