- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to reduce project risks through innovative solutions of PCBA factories?

2025-05-23

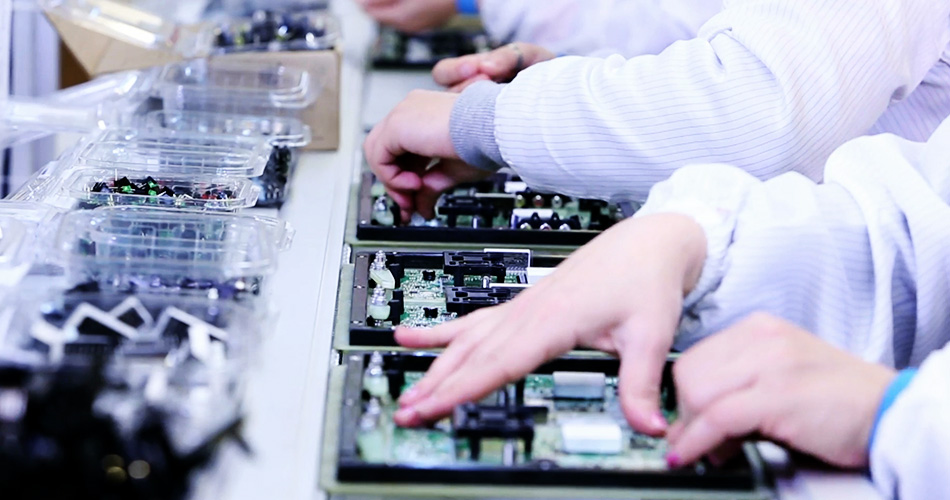

In the PCBA processing industry, the smooth delivery of projects is often affected by various risk factors, such as quality issues, production delays and supply chain disruptions. Therefore, choosing a PCBA factory with innovative solutions can not only improve production efficiency, but more importantly, it can significantly reduce project risks and ensure the smooth completion of the project. This article will explore how PCBA factories can reduce project risks through innovative technologies and management methods.

1. Optimize production processes: improve efficiency and stability

Optimizing production processes is the primary strategy for PCBA factories to achieve risk control. By introducing automated and intelligent production equipment, factories can effectively reduce human errors, improve production stability and efficiency, and thus reduce project risks.

Application of automated equipment: Automated equipment can help factories reduce errors caused by manual operations, improve production accuracy and consistency, and thus reduce the risk of defective products.

Intelligent monitoring system: By tracking the production process through a real-time monitoring system, the factory can make adjustments in the early stages of the problem to prevent small problems from turning into big risks.

Optimizing production processes can not only reduce the risk of failures in the production process, but also improve the reliability of delivery.

2. Flexible supply chain management: reduce raw material supply risks

PCBA processing projects often rely on multiple suppliers for raw material supply, which means that any delays or fluctuations in the supply chain may cause project delays. Through innovative supply chain management solutions, PCBA factories can flexibly respond to supply chain problems and reduce the risks of raw material shortages.

Diversified supply chain structure: Establish a diversified supply chain network to ensure that when a supplier has problems, alternative resources can be quickly found to ensure the continuity of production.

Supply chain digital management: Through real-time monitoring of raw material inventory and delivery status through supply chain management software, PCBA factories can detect possible supply risks in advance and respond in a timely manner.

Flexible supply chain management can effectively reduce raw material risks and provide guarantees for on-time delivery of projects.

3. Strengthen quality control: reduce rework and quality problems

Quality problems not only affect product delivery, but also lead to customer dissatisfaction and increase the overall risk of the project. PCBA factories can reduce rework and quality problems through innovative quality control methods and advanced testing equipment to ensure that products meet customer quality requirements.

Full-process quality management system: From raw material procurement, production to finished product delivery, full-process quality management can ensure that every link meets the standards, thereby reducing quality risks.

Advanced detection technology: The introduction of advanced detection technologies such as AOI (automatic optical inspection) and ICT (in-line testing) can accurately detect the quality of each PCBA product and reduce the defective rate.

Through strict quality control, PCBA factories can significantly reduce the risks caused by product quality problems.

4. Strengthen project management: Improve the controllability of delivery

A perfect project management system is the core means for PCBA factories to control project risks. Through innovative project management methods, factories can ensure the orderly progress of production plans and improve the controllability of project delivery.

Agile project management method: Agile project management can help PCBA factories flexibly respond to changes in the production process, and achieve efficient control of projects through phased management and continuous improvement.

Real-time data analysis: Through real-time analysis of production data, project managers can promptly discover anomalies in the production process and take quick measures to avoid the expansion of problems.

Innovative project management methods can help PCBA factories better respond to emergencies and ensure the smooth implementation of projects.

5. Customer collaboration and feedback mechanism: reduce customer satisfaction risk

Customer feedback is an important risk control factor in PCBA processing projects. By establishing a close customer collaboration mechanism, the factory can understand customer needs in a timely manner, respond to customer feedback quickly, and avoid risks caused by poor communication or changes in demand.

Project phase review with customer participation: Invite customers to participate in the review of key nodes of each project, so that customers have a clear understanding of the project progress and reduce their doubts about the project.

Quick response to customer feedback: By establishing a quick feedback mechanism, the factory can quickly adjust the production plan to meet the sudden needs of customers, thereby improving customer satisfaction.

Establishing a good customer collaboration mechanism can help PCBA factories effectively avoid customer dissatisfaction risks and increase customer trust in the factory.

Conclusion

In PCBA processing projects, innovative solutions are the key means for factories to reduce project risks. By optimizing production processes, flexible supply chain management, strict quality control, innovative project management methods and active customer collaboration, PCBA factories can significantly reduce various project risks and increase the success rate of projects. In the future, with the continuous development of technology, PCBA factories can further utilize new technologies and innovative management methods to enhance project risk control capabilities and provide customers with a better service experience.

-

Delivery Service

-

Payment Options