- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Discussion on the multi-variety and small batch production mode of PCBA factory

2025-05-22

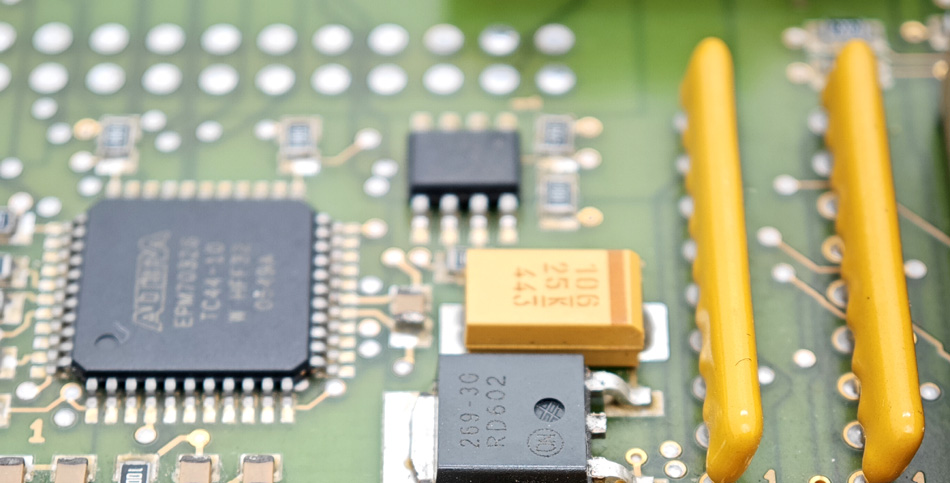

In today's electronic manufacturing industry, the market demand for product diversity and customization is growing, prompting PCBA(Printed Circuit Board Assembly) factories to turn to a multi-variety and small batch production mode. This mode can help companies respond to market demand quickly and meet customers' requirements for personalization and flexibility. However, the multi-variety and small batch production mode also brings challenges in management and efficiency. This article will explore in depth how PCBA processing factories can cope with these challenges through reasonable strategies to achieve higher production efficiency and market competitiveness.

1. Characteristics of multi-variety and small batch production mode

The multi-variety and small batch production mode refers to the production of multiple models or specifications of products at the same time under limited production capacity, and the production quantity of each product is relatively small. The characteristics of this mode are:

Quick response to market demand: multi-variety production can meet customers' diverse needs for different products.

Strong flexibility: The factory can quickly adjust the production plan according to customer orders and market demand, and increase or reduce the output of specific products.

Personalized customization: Through this production mode, PCBA factories can achieve a higher degree of customization to meet customer specific needs.

However, this mode also puts higher requirements on production management and equipment flexibility.

2. Challenges of the multi-variety and small batch mode

Although the multi-variety and small batch production mode can enhance the market adaptability of PCBA processing, it is also accompanied by the following challenges:

Long production preparation time: Each product needs to be prepared for process, material preparation and equipment adjustment before production, which increases the production preparation time and affects the overall production efficiency.

Increased production costs: Compared with mass production, the costs of material procurement, inventory management, etc. for multi-variety and small batch production are relatively high.

Complex production scheduling management: Multi-variety production requires frequent adjustments to production plans, which increases the complexity of production scheduling and equipment switching.

Faced with these challenges, PCBA factories need to develop effective strategies to optimize production processes and improve production efficiency.

3. Key strategies for achieving multi-variety and small batch production

To successfully implement the multi-variety and small batch production mode in PCBA processing, factories can adopt the following strategies:

Introducing flexible manufacturing systems

Flexible manufacturing systems (FMS) refer to the use of flexible equipment and flexible processes in the production process to adapt to diversified production needs. PCBA factories can reduce downtime caused by product changes by introducing automated production lines and flexible process settings. For example, the use of programmable devices and modular fixtures can quickly adapt to different product specifications and improve production efficiency.

Strengthen the production management system

Production management systems (such as ERP and MES systems) can help factories monitor production progress, inventory status, and equipment operation in real time. Through these systems, PCBA factories can better arrange production plans and optimize material flow, thereby reducing inventory pressure and controlling costs. In addition, the production management system can also realize information sharing and rapid feedback, which helps to adjust production strategies in a timely manner and ensure on-time delivery of orders.

Establish efficient supply chain management

Multi-variety small-batch production has high requirements for material supply. PCBA factories should establish close cooperative relationships with suppliers to ensure the timely supply of key materials. At the same time, the "on-demand procurement" model can be adopted to reduce inventory pressure and avoid material backlogs. In addition, it is also possible to communicate with suppliers to shorten the supply cycle and improve the flexibility of material supply, so as to better meet the production needs of small-batch orders.

Optimize equipment switching and maintenance

In multi-variety production, equipment switching is frequent. PCBA factories can shorten equipment adjustment time and improve production efficiency by introducing fast switching technology (such as quick-change fixtures). At the same time, formulate regular maintenance plans to reduce production interruptions caused by equipment failures and ensure the stability of multi-variety small batch production.

4. Advantages of multi-variety small batch mode

Although multi-variety small batch production faces some challenges, if it can be dealt with reasonably, this mode will bring significant advantages to PCBA factories:

Meet customer needs: The multi-variety small batch production mode can quickly respond to customer needs, improve customer satisfaction, and enhance customer loyalty.

Improve market competitiveness: In a market environment where customization and small batch demand are gradually increasing, this production mode can enable PCBA factories to maintain competitiveness and occupy market advantages.

Increase profit margins: Although the unit cost of small batch production is high, the added value of multi-variety products is also high, giving the factory a strong profit margin.

Conclusion

The multi-variety small batch production mode in PCBA processing has become a key means to adapt to market changes and meet the diverse needs of customers. PCBA factories can effectively respond to the challenges of multi-variety small batch production and achieve stable and efficient production processes by introducing flexible manufacturing systems, strengthening production management, optimizing supply chain management and equipment maintenance. In the future, with the continuous changes in customer needs and the rapid development of the market, the multi-variety and small-batch model will become an important choice for PCBA processing factories to maintain their competitiveness.

-

Delivery Service

-

Payment Options