- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Capacity upgrade: How can PCBA factories achieve high-speed patching?

2025-05-21

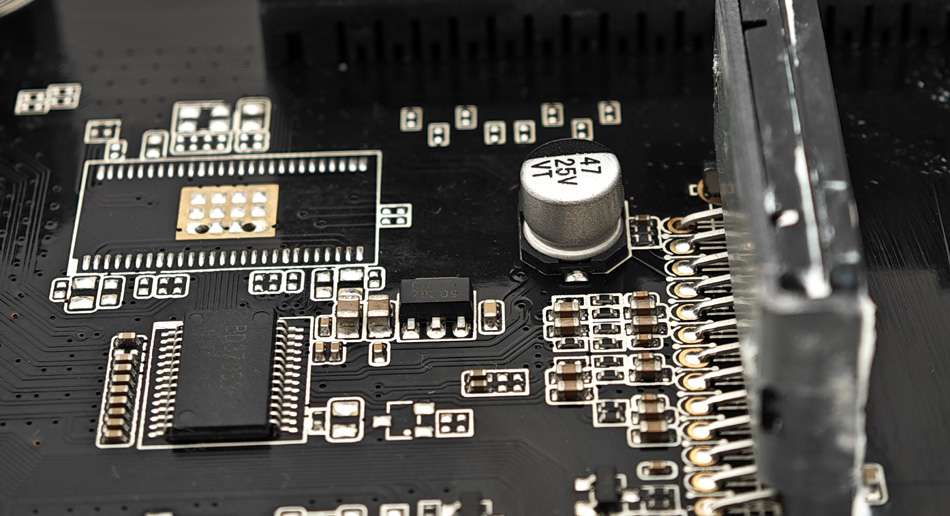

With the rapid development of the electronic products market, customers' demand for PCBA(Printed Circuit Board Assembly) processing speed and capacity is constantly increasing. As the core link in PCBA processing, high-speed patching is crucial to improving overall production efficiency. How to achieve high-speed patching and optimize production capacity in PCBA factories has become an important topic in the current industry. This article will discuss how PCBA factories can achieve capacity upgrades through high-speed patching from the aspects of key technologies, equipment selection and management strategies.

1. The importance of high-speed patching in PCBA processing

High-speed patching refers to the process of quickly and accurately pasting components to designated positions on printed circuit boards (PCBs). The speed and quality of patching directly affect the production cycle and product yield of PCBA processing. High-speed patching can not only shorten production time, but also improve the factory's order processing capabilities, making PCBA factories more competitive in the market.

2. Key technologies for achieving high-speed patching

To achieve high-speed patching, PCBA factories need to introduce a series of advanced technologies to ensure the speed and accuracy of the patching process.

Automated patching equipment

Automated patching equipment is the key to achieving high-speed patching. The current high-end SMT machines on the market can achieve a mounting speed of hundreds of thousands of components per hour. PCBA factories can choose appropriate SMT equipment according to their own production capacity requirements, improve the picking efficiency of components through multi-head mounting and multi-nozzle design, reduce the moving path, and thus achieve high-speed production.

Intelligent Vision System

High-speed SMT has extremely high requirements for accuracy, so it needs the support of intelligent vision system. Intelligent vision system can detect PCB position and component size in real time, quickly adjust the SMT position, and improve the accuracy of mounting. This system can help PCBA factories reduce the SMT error rate, reduce the rework rate, and further increase production capacity.

Efficient transmission technology

In order to reduce the non-productive time in the production process, PCBA factories can use high-speed transmission technology to efficiently connect SMT equipment with other production equipment to form a coherent assembly line operation. High-speed transmission system can speed up the movement speed of PCB in the production line, thereby improving the utilization rate and output rate of SMT machines.

3. Selection and configuration of high-speed SMT equipment

In the process of achieving high-speed SMT, the selection and configuration of equipment are very important. When choosing high-speed SMT equipment, PCBA processing factories need to comprehensively consider SMT speed, compatibility and stability.

Choose high-precision, high-speed SMT machines

SMT machines of different brands and models vary in speed and precision. PCBA factories need to choose high-precision SMT machines according to product requirements to ensure accurate placement of small-sized components. At the same time, the speed of high-speed SMT machines can significantly improve production efficiency and adapt to high production capacity requirements.

Reasonable configuration of equipment and production lines

To achieve true high-speed production, PCBA factories not only need high-speed SMT machines, but also need to reasonably configure other production equipment. By configuring high-speed AOI inspection, automated solder paste printers and other equipment, the factory can form a complete production closed loop, reduce human intervention, and realize a fully automated and efficient production process.

4. Optimize management to support high-speed SMT

In addition to hardware equipment and technical support, PCBA factories also need to optimize production management to ensure the smooth implementation of high-speed SMT. A good management system can help factories reduce equipment failure rates, optimize production plans, and thus improve production efficiency.

Implement lean production management

High-speed patch in PCBA processing requires the support of lean production management to reduce waste and optimize production processes. By implementing lean management, factories can promptly discover production bottlenecks, optimize the configuration of equipment and human resources, and further improve capacity utilization.

Strengthen equipment maintenance and training

The efficient operation of high-speed patch equipment is inseparable from daily maintenance and professional training of operators. PCBA factories should establish a complete equipment maintenance system, regularly inspect and maintain patch machines and visual systems, and ensure the stability of equipment under high-speed operation. At the same time, provide professional training for operators to help them master the operation skills of the equipment and improve production efficiency.

5. Advantages and future development of high-speed patch

By realizing high-speed patch, PCBA factories can significantly improve production capacity and competitiveness. High-speed patch not only improves the speed of product delivery, but also enhances the factory's order processing capabilities, enabling it to cope with more order requirements and shorter delivery requirements.

In the future, with the continuous development of intelligent manufacturing technology, high-speed patch in PCBA processing will also be more intelligent and automated. Advanced AI and IoT technologies are expected to further improve the efficiency and precision of SMT machines, bringing the production capacity and quality of PCBA factories to a higher level.

Conclusion

High-speed SMT is an important means to achieve capacity upgrades in PCBA processing. By introducing automated SMT equipment, intelligent visual systems, and efficient transmission technology, PCBA factories can significantly improve production efficiency. In addition, reasonable equipment configuration and scientific management models are also crucial to the successful implementation of high-speed SMT. In the future, with the continuous development of high-speed SMT technology, PCBA factories will be more competitive and able to meet the growing capacity needs of the electronics manufacturing industry.

-

Delivery Service

-

Payment Options