- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Complex design problems and solutions in PCBA processing

2025-05-15

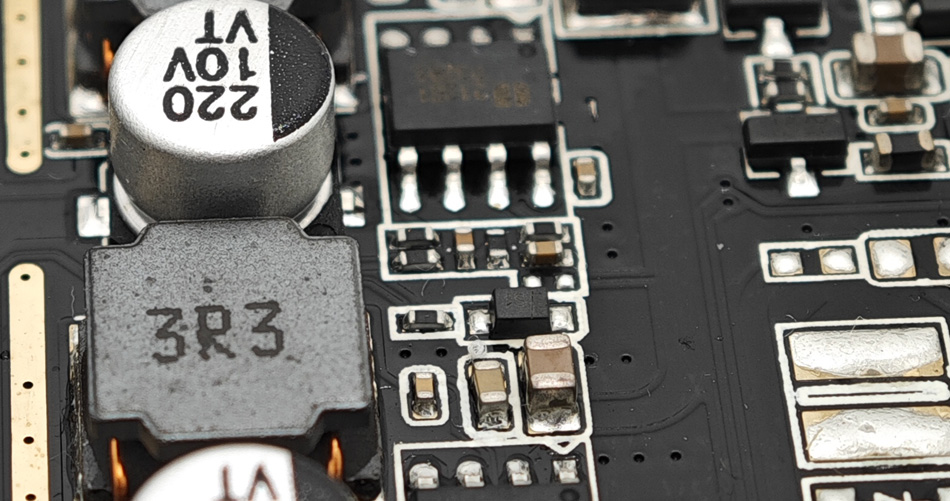

In the process of PCBA (Printed Circuit Board Assembly), complex design problems are an important factor affecting production efficiency and product quality. Complex design not only increases the difficulty of manufacturing, but may also cause a series of quality problems. This article will explore the complex design problems in PCBA processing and their solutions to help companies improve production efficiency and product reliability.

1. Main types of complex design problems

In PCBA processing, common complex design problems include:

High-density wiring: As electronic products develop towards miniaturization and high-function integration, the wiring on the circuit board becomes more and more complex, which easily leads to signal interference and wiring congestion.

Multi-layer circuit boards: Multi-layer circuit boards require precise alignment and soldering during the manufacturing process, which increases the difficulty and risk of production.

Complex component layout: High-density and complex component layout may increase the difficulty of assembly, affecting soldering quality and assembly accuracy.

Special functional requirements: Special functional requirements such as high-speed signal transmission and high-frequency applications put forward higher requirements for the design and manufacture of circuit boards.

2. Solutions to high-density wiring

The problem of high-density wiring is mainly reflected in signal interference and insufficient wiring space. This can be solved by the following strategies:

Optimize wiring design: Use high-frequency wiring design rules to lay out signal lines reasonably, avoid long lines and cross lines, and reduce signal interference.

Use multi-layer boards: Distribute circuits in multiple layers, use the inner layer as the signal layer, and the outer layer as the power layer or ground layer to optimize the wiring space.

Apply signal integrity analysis: Use signal integrity analysis tools to evaluate the impact of wiring on signals, and make necessary adjustments and optimizations.

3. Manufacturing challenges and responses for multi-layer circuit boards

The manufacturing of multi-layer circuit boards requires precise alignment and stable inter-layer connections. Strategies include:

Strictly control the production process: Ensure the accuracy and consistency of each manufacturing link (such as lamination, drilling, and soldering) to prevent inter-layer misalignment and poor connection.

Use high-precision equipment: Invest in high-precision production equipment and testing instruments to improve the stability of the manufacturing process and product quality.

Perform multi-layer board testing: During the production process, perform multi-layer board testing to check the inter-layer connection quality and electrical performance, and promptly discover and correct problems.

4. Optimization of complex component layout

Complex component layout may lead to increased difficulty in assembly and soldering. Optimization strategies include:

Modular design: Design the circuit board into multiple modules to simplify the layout and assembly process and reduce complexity.

Use automated equipment: Use automated placement machines and soldering equipment to improve the placement accuracy and consistency of components.

Improve soldering process: For complex layouts, adjust soldering process parameters to ensure solder joint quality and connection stability.

5. Countermeasures for special function design

For designs with special functions (such as high-speed signal transmission), the following measures can be taken:

Design optimization: Optimize the design for specific functions, such as optimizing signal paths, improving anti-interference capabilities, and using high-frequency materials.

Perform simulation analysis: Use simulation tools to perform performance analysis during the design phase, evaluate the impact of the design on special functions, and make necessary adjustments.

Select appropriate materials: Select appropriate circuit board materials and components according to functional requirements to ensure that performance requirements are met.

6. Design Verification and Testing

Verifying and testing complex designs is the key to ensuring successful production:

Conduct design reviews: Conduct detailed design reviews during the design phase to identify and solve potential problems.

Conduct prototype testing: Produce samples for testing to verify the feasibility and performance of the design, and discover and solve problems early.

Implement production testing: Perform rigorous testing during the production process to ensure that the product meets design requirements and quality standards.

Conclusion

In PCBA processing, complex design issues are important challenges faced during the production process. By optimizing wiring design, strictly controlling multi-layer board manufacturing processes, improving component layout, responding to special functional design requirements, and conducting sufficient design verification and testing, companies can effectively solve the problems caused by complex designs and improve production efficiency and product quality. These strategies not only help to enhance the competitiveness of companies in the market, but also promote the sustainable development of their business.

-

Delivery Service

-

Payment Options