- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to overcome the cost overrun problem in PCBA processing

2025-05-14

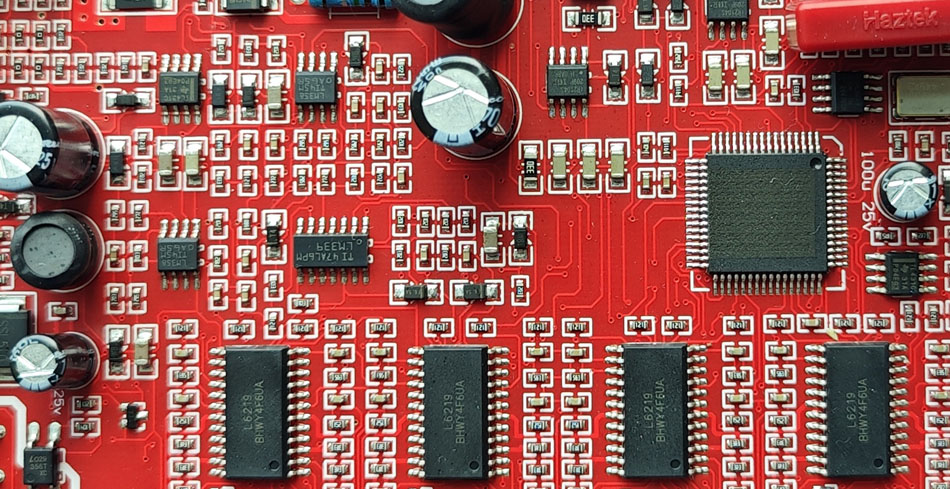

In PCBA (Printed Circuit Board Assembly) processing, cost control is an important challenge faced by every manufacturing company. Cost overruns not only affect the company's profit margins, but may also lead to a decline in competitiveness. This article will explore how to effectively overcome the cost overrun problem in PCBA processing and help companies achieve cost optimization while ensuring quality.

1. Optimize design to reduce costs

Design is one of the key factors affecting PCBA processing costs. Optimizing design can significantly reduce production costs:

Simplify design: During the design stage, try to simplify the structure of the circuit board. Complex design not only increases the difficulty of production, but may also lead to increased material and assembly costs.

Standardize components: Choose standardized and common electronic components. This not only helps to reduce procurement costs, but also reduces the complexity of inventory management.

Design for Manufacturability (DFM): Apply DFM principles to ensure that the design is easy to manufacture and assemble. This can reduce problems in the production process, thereby reducing the cost of rework and repair.

2. Improve procurement efficiency

Procurement costs are another major source of expenses in PCBA processing. By improving procurement efficiency, costs can be effectively controlled:

Multi-supplier procurement: Establish cooperative relationships with multiple suppliers to increase competition and obtain more advantageous prices. Avoid relying on a single supplier to reduce cost increases caused by supply chain disruptions.

Centralized procurement: By centrally purchasing large quantities of components, lower unit prices can usually be obtained. Negotiate bulk purchase discounts with suppliers to reduce material costs.

3. Implement lean production

Lean production methods can help reduce waste in PCBA processing and thus reduce costs:

Reduce scrap rate: Reduce scrap rate by improving production processes and quality control. High scrap rate not only increases material waste, but also increases the cost of handling scrap.

Optimize production processes: Analyze and optimize production processes, eliminate unnecessary steps and links, and improve production efficiency. This not only saves time, but also reduces manpower and equipment costs.

4. Control process and test costs

Process and testing are important links in PCBA processing. It is crucial to effectively control the costs of these links:

Choose the right process: Choose the most appropriate process according to product requirements. For example, for some simple products, a lower-cost soldering process can be selected, while a more efficient automated process can be used for complex products.

Optimize the test process: During the test phase, use automated test equipment to improve test efficiency and reduce labor costs. At the same time, ensure that the test process can accurately detect problems and avoid later rework and repairs caused by insufficient testing.

5. Invest in advanced technology

The application of advanced technology can significantly improve production efficiency and reduce costs:

Automated equipment: Invest in automated production lines and equipment to improve production speed and accuracy and reduce labor costs. Automated equipment can also reduce human errors and improve product consistency.

Real-time data analysis: Use real-time data analysis tools to monitor key indicators in the production process. Through data analysis, potential problems can be discovered in a timely manner and preventive measures can be taken to avoid cost increases caused by problems not being discovered in a timely manner.

6. Establish an effective cost control mechanism

Establishing a scientific cost control mechanism helps manage and control various expenses in PCBA processing:

Budget management: Develop a detailed budget plan and regularly compare and analyze actual expenditures with the budget. Adjust the budget in a timely manner to ensure that all expenses are within a controllable range.

Cost audit: Conduct cost audits regularly to review the expenses in production and procurement, find out the reasons for overspending and take corrective measures.

Conclusion

Overcoming the cost overspending problem in PCBA processing requires multiple aspects, including optimizing design, improving procurement efficiency, implementing lean production, controlling process and testing costs, investing in advanced technology, and establishing an effective cost control mechanism. Through a systematic cost management strategy, companies can not only reduce production costs, but also improve overall production efficiency and product quality, thereby gaining an advantage in the highly competitive market.

-

Delivery Service

-

Payment Options