- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Soldering quality problems and improvement methods in PCBA processing

2025-05-16

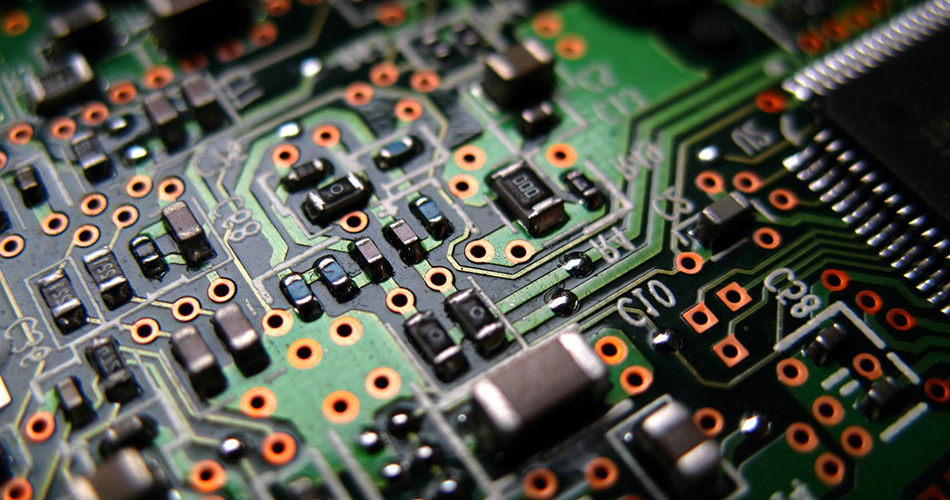

In PCBA (Printed Circuit Board Assembly) processing, soldering quality directly affects the overall reliability and performance of the product. Poor soldering can lead to product failure, performance degradation, and may even cause the entire production line to stagnate. This article will explore common soldering quality problems in PCBA processing and provide targeted improvement methods to help improve soldering quality and production efficiency.

1. Common soldering quality problems

In PCBA processing, common soldering quality problems include:

Solder joints are not soldered: The solder joints are not firmly connected, which may cause poor circuit contact.

Over-soldering of solder joints: Too much solder may cause short circuits or interfere with signal transmission.

Insufficient solder joints: Insufficient solder may cause unstable connections or open circuits.

Solder bridging: The solder between adjacent solder joints forms a bridge, which may cause a short circuit.

Solder joint cracking: Cracks appear in the solder joints after soldering, which may cause insufficient mechanical strength or poor electrical contact.

2. Cause analysis of soldering quality problems

Solving soldering quality problems requires in-depth understanding of the causes of their occurrence, mainly including:

soldering material problems: The composition or quality of the solder does not meet the requirements, which may affect the soldering effect.

soldering process problems: Incorrect soldering temperature, time or other process parameters may cause soldering defects.

Equipment problems: Insufficient precision or poor maintenance of soldering equipment may lead to unstable soldering quality.

Operation problems: The technical level or operating specifications of the operator are not rigorous, which may cause poor soldering.

3. Methods to improve soldering quality

In order to improve the soldering quality in PCBA processing, the following improvement measures can be taken:

3.1 Optimize soldering process

Optimizing soldering process is the key to improving soldering quality. Enterprises should:

Adjust soldering parameters: According to different soldering materials and components, adjust parameters such as soldering temperature, time and speed to ensure a stable soldering process.

Use suitable solder: Select solder with reliable quality and suitable for specific applications to ensure solder joint strength and electrical performance.

Improve soldering process: Optimize the soldering process to reduce the occurrence of soldering defects, such as using preheating process or using hot air reflow soldering.

3.2 Regularly maintain soldering equipment

Maintenance of soldering equipment is crucial to soldering quality. Enterprises should:

Regularly calibrate equipment: ensure the accuracy of soldering equipment and avoid soldering problems caused by equipment deviation.

Check equipment status: Regularly check various components of soldering equipment, including nozzles, heating elements and transmission systems, to ensure that the equipment is in good working condition.

Clean equipment: Keep the equipment clean to avoid solder residue or contaminants affecting the soldering effect.

3.3 Improve operator skills

The skill level of operators directly affects the quality of soldering. Enterprises should:

Provide training: Regularly provide soldering technology training to operators to improve their professional skills and operating specifications.

Implement operating specifications: Develop detailed operating specifications and standards to ensure that operators operate in accordance with the specifications and reduce soldering defects caused by human factors.

3.4 Conduct strict quality inspections

Strict quality inspections can detect and solve soldering problems early. Enterprises should:

Implement online inspections: Use online inspection technologies such as automatic optical inspection (AOI) to monitor soldering quality in real time.

Conduct post-testing: Ensure that the soldering quality meets product requirements through functional testing and environmental testing.

Record and analyze data: Collect data during the soldering process, analyze defects, identify common problems and develop improvement plans.

Conclusion

In PCBA processing, soldering quality issues are an important factor affecting product reliability and production efficiency. By optimizing the soldering process, regularly maintaining soldering equipment, improving operator skills and conducting strict quality inspections, companies can effectively improve soldering quality and reduce failure rates. These improvement measures not only help improve product quality, but also enhance the competitiveness of companies in the market.

-

Delivery Service

-

Payment Options