- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

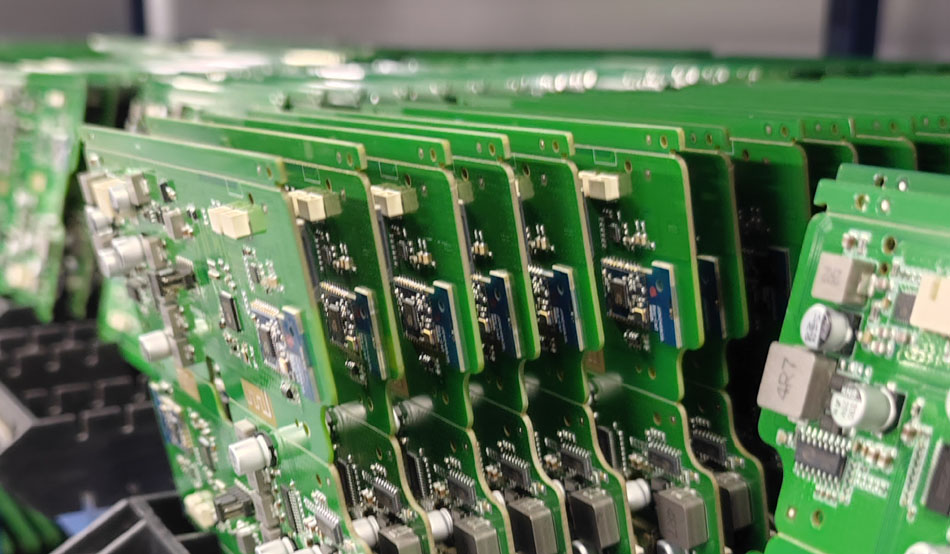

Countermeasures for supply chain disruption in PCBA processing

2025-05-13

In a globalized market environment, the stability of the supply chain is critical to the success of an enterprise. Especially in the PCBA (Printed Circuit Board Assembly) processing industry, supply chain disruptions may seriously affect production schedules and costs. This article will explore countermeasures for supply chain disruptions in PCBA processing to help companies maintain business continuity and reduce potential losses.

1. Common causes of supply chain disruptions

In PCBA processing, supply chain disruptions may be caused by a variety of factors, including:

Raw material shortages: Raw materials may be in short supply due to natural disasters, political unrest, or insufficient supplier production capacity.

Transportation issues: Logistics delays or transportation disruptions may prevent key components from arriving on time.

Supplier bankruptcy: The financial problems of suppliers may prevent them from fulfilling their contracts, affecting the normal progress of PCBA processing.

2. Establish a diversified supplier network

To reduce the risk of supply chain disruptions, PCBA processing companies should consider establishing a diversified supplier network. By working with multiple suppliers, companies can reduce their dependence on a single supplier, allowing them to quickly find alternatives when problems arise. This not only helps maintain production stability, but also provides more options in terms of price and quality.

3. Implement supply chain risk assessment

Performing supply chain risk assessment regularly is the key to identifying potential problems and developing response strategies. By analyzing each link in the supply chain, companies can identify possible risk points and develop emergency plans in advance. This includes evaluating the financial health, transportation capacity, and production capacity of suppliers.

4. Establish an inventory buffer mechanism

During the PCBA processing process, establishing a reasonable inventory buffer mechanism can effectively respond to supply chain disruptions. Companies can maintain a certain amount of safety inventory based on demand forecasts and production plans. This will help companies maintain production operations and meet customer needs when encountering supply disruptions.

5. Adopt advanced supply chain management systems

Modern supply chain management systems can provide real-time data monitoring and analysis to help companies identify and respond to supply chain problems in a timely manner. By using advanced supply chain management software, companies can improve visibility into supply chain conditions and make faster and more accurate decisions.

6. Strengthen supplier relationship management

Establishing a good cooperative relationship with suppliers is an effective means to reduce the risk of supply chain disruptions. Through regular communication and cooperation, companies can enhance suppliers' willingness to cooperate and receive priority support when problems arise. In addition, signing clear contracts and service level agreements (SLAs) with suppliers can ensure that suppliers can respond quickly when problems occur.

7. Develop contingency plans

Despite various measures taken to reduce the risk of supply chain disruptions, unexpected situations may still occur. Therefore, it is essential to develop a detailed contingency plan. The contingency plan should include response strategies, alternatives, and resource allocation plans for various potential problems. By rehearsing contingency plans, companies can ensure that normal production can be quickly restored when supply chain disruptions occur.

Conclusion

Supply chain disruptions are a major challenge facing PCBA processing companies, but by establishing a diversified supplier network, implementing supply chain risk assessments, establishing inventory buffer mechanisms, adopting advanced supply chain management systems, strengthening supplier relationship management, and developing contingency plans, companies can effectively reduce the risk of supply chain disruptions. Maintaining flexibility and resilience will help companies maintain competitiveness and business continuity in an uncertain market environment.

-

Delivery Service

-

Payment Options