- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Human errors in PCBA processing: How to reduce the impact?

2025-05-12

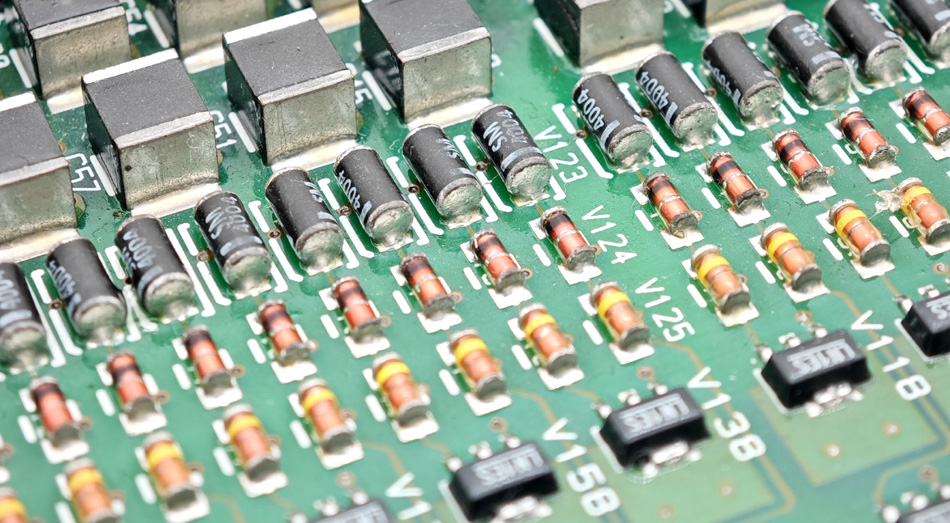

In PCBA (Printed Circuit Board Assembly) processing, human errors are an important factor affecting production efficiency and product quality. Human errors not only lead to product defects, but may also cause rework and additional repair costs. Therefore, effectively reducing the impact of human errors is the key to improving production quality and efficiency. This article will explore how to reduce the impact of human errors in PCBA processing, thereby optimizing production processes and improving product quality.

1. Standardized operating procedures

Standardized operating procedures can effectively reduce the occurrence of human errors:

Develop standard operating instructions: Write detailed operating instructions covering all production and assembly steps. These instructions should clarify each operating step to ensure that workers can operate in accordance with the specifications.

Implement standardized training: Conduct systematic training for employees to ensure that they understand and can proficiently perform standard operating procedures. Update training content regularly to reflect the latest operating specifications and technical requirements.

2. Introduce automated equipment

Automated equipment can significantly reduce the occurrence of human errors:

Automated assembly: Invest in automated assembly equipment, such as automatic placement machines and soldering robots, which can improve assembly accuracy and reduce errors caused by improper human operation.

Automated inspection system: Real-time inspection using automated inspection systems (such as automatic optical inspection, AOI) can promptly detect and correct errors in production, reducing the burden and error rate of manual inspection.

3. Strengthen quality control

Quality control is the key to ensuring that every link in the production process meets standards:

Process inspection: Conduct process inspections at all stages of production to promptly detect and correct problems. For example, inspections are conducted after key operating steps to ensure that each step meets requirements.

Final inspection: Final inspection is conducted after production is completed to check whether the product meets specifications and quality standards. Through strict final inspection, defective products caused by human errors can be screened out.

4. Optimize the working environment

The working environment has a direct impact on the operating accuracy of employees:

Good working conditions: Provide a good working environment, including sufficient light, a comfortable workbench and appropriate tools. Good working conditions help improve employees' operating accuracy and comfort.

Reduce distractions: Ensure that the production area is quiet and minimize unnecessary distractions. Distractions may distract employees and increase the probability of operational errors.

5. Use a quality feedback system

The quality feedback system can help identify and solve problems in a timely manner:

Real-time feedback: Establish a real-time feedback mechanism so that employees can quickly report and solve problems in operation. Through rapid feedback and adjustments, the spread and impact of errors can be reduced.

Data recording and analysis: Record and analyze error data that occurs during the production process to identify common problems and trends. Based on this data, take targeted improvement measures to prevent the recurrence of similar errors.

6. Implement process improvement

Process improvement is an effective means to continuously reduce the impact of human errors:

Continuous improvement: Regularly evaluate and optimize the production process, identify and improve links that may cause errors. Implement improvement measures to improve production efficiency and accuracy.

Employee participation: Encourage employees to participate in the improvement process, and through their feedback and suggestions, discover and solve problems encountered in actual operations. Employee participation can improve the effectiveness and acceptance of improvement measures.

7. Establish a reward and punishment system

An effective reward and punishment system can motivate employees to maintain a high level of operating accuracy:

Reward mechanism: Reward employees with excellent performance and accurate operation to motivate them to maintain good operating habits. The reward mechanism can improve employees' enthusiasm and work quality.

Corrective measures: Provide targeted training and guidance to employees who frequently make mistakes to help them correct problems in operation and reduce the error rate.

Conclusion

Reducing the impact of manual errors in PCBA processing requires multiple aspects, including standardized operating procedures, introduction of automated equipment, strengthening quality control, optimizing the working environment, using quality feedback systems, implementing process improvements, and establishing a reward and punishment system. By combining these strategies, the occurrence of manual errors can be effectively reduced, production quality and efficiency can be improved, and the smooth progress of the PCBA processing process can be ensured. Taking active measures to deal with manual errors will help improve the overall production level and enhance the competitiveness of the enterprise.

-

Delivery Service

-

Payment Options