- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to deal with the challenges of design changes in PCBA processing

2025-05-10

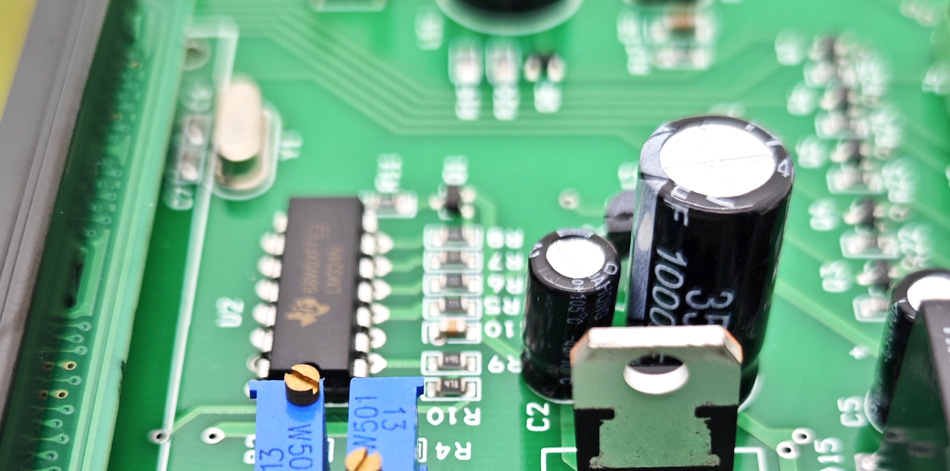

Design changes are an inevitable part of PCBA (Printed Circuit Board Assembly) processing. Design changes may occur due to customer needs, technological advances, or market feedback. Although design changes can improve the functionality and competitiveness of products, they also bring a series of challenges, such as production process adjustments, material management, and quality control. This article will explore how to effectively deal with the challenges of design changes in PCBA processing to ensure smooth production and high product quality.

I. Understanding the impact of design changes

1. Adjustment of production processes

Process changes: Design changes may require adjustments to existing production processes. For example, adding or replacing components, modifying circuit designs, etc., all require re-evaluation and adjustment of production processes.

Equipment adjustments: Some design changes may require reconfiguration or calibration of production equipment to adapt to new production requirements.

2. Material management

Introduction of new materials: Design changes may introduce new materials or components, which requires timely updating of the bill of materials and procurement plans to ensure that the supply of new materials is in place in a timely manner.

Inventory management: Materials of old designs may need to be processed or cleared. Manage inventory reasonably to avoid unnecessary inventory backlogs and waste.

3. Quality control

Inspection standard update: Design changes may affect the inspection standards of products, and quality control processes and testing methods need to be updated to ensure that the new design meets quality requirements.

Test verification: New designs need to be tested and verified to ensure that the functions and performance in actual applications meet the expected standards.

II. Strategies for effectively handling design changes

1. Establish a change management process

Change request evaluation: Before the design change is implemented, establish a strict change request evaluation process to evaluate the necessity of the change and the impact on production. Ensure that the change request is reviewed and approved to avoid unnecessary changes.

Change records and communication: Record all design change information, including the reasons for the change, implementation plan and expected impact. Ensure timely communication between relevant departments and teams to maintain transparency and consistency of information.

2. Optimize the implementation of design changes

Design verification: Before the design change is implemented, conduct sufficient design verification and simulation testing to ensure the feasibility and stability of the new design. Reduce potential problems after the change is implemented through verification.

Gradual implementation: For complex design changes, it is recommended to implement them in stages. Gradual implementation can reduce interference with production and facilitate monitoring and adjustment of implementation effects.

3. Update production and material management

Adjust production processes: According to design changes, timely adjust production processes and processes. Make necessary equipment adjustments and process improvements to adapt to new design requirements.

Material procurement and management: Update material procurement plans and inventory management strategies according to new design requirements. Ensure timely supply of new materials and reasonable handling of old material inventory.

4. Strengthen quality control

Update inspection standards: According to design changes, update product inspection standards and test methods. Ensure that the quality control process can cover all key parameters of the new design.

Conduct comprehensive testing: Conduct comprehensive functional and performance tests on the changed products to ensure that the new design can achieve the expected results in actual applications.

5. Training and support

Operator training: Train production and inspection personnel to ensure that they master the new design changes and operating requirements. The training content should include the use of new processes, new materials and the implementation of new quality standards.

Technical support: Provide technical support and consultation to help relevant teams solve problems encountered during the design change process. Through technical support, ensure the smooth implementation of changes and the stability of production.

Conclusion

Dealing with the challenges of design changes in PCBA processing requires companies to develop effective change management strategies and carry out careful planning and coordination during the implementation process. By establishing a sound change management process, optimizing design change implementation, updating production and material management, strengthening quality control, and providing training and technical support, companies can effectively respond to the challenges brought by design changes and ensure smooth production and high product quality. In a highly competitive market environment, companies should continue to pay attention to the management practices of design changes and continuously improve their response capabilities to meet customer needs and market development.

-

Delivery Service

-

Payment Options