- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Root causes and countermeasures for production delays in PCBA processing

2025-05-09

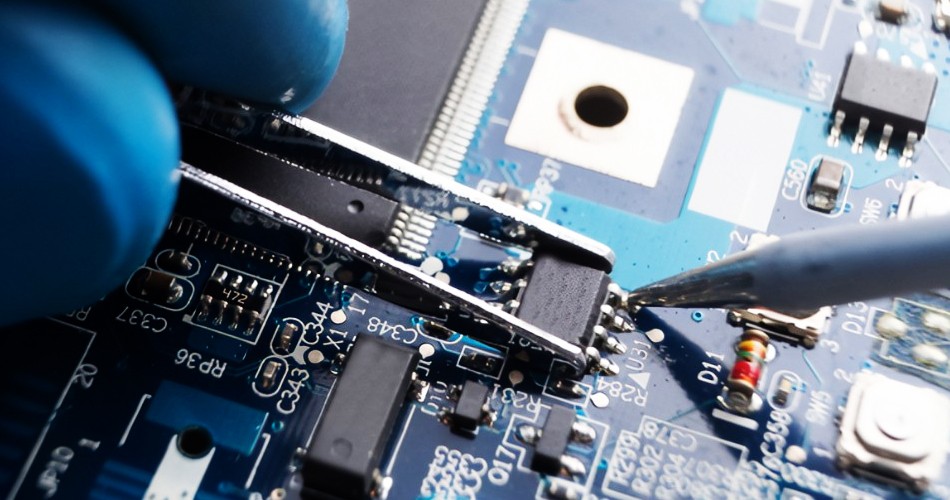

In the process of PCBA (Printed Circuit Board Assembly), production delays are one of the common challenges. Production delays not only affect delivery time, but may also lead to customer dissatisfaction and damage to the company's reputation. Understanding the root causes of production delays and taking effective countermeasures are crucial to ensuring production efficiency and improving customer satisfaction. This article will explore the main causes of production delays in PCBA processing and provide corresponding countermeasures.

I. Root causes of production delays

1. Material supply issues

Material shortages: In PCBA processing, insufficient material supply is a common cause of delays. The production line may be stagnant due to untimely delivery from suppliers, inaccurate material demand forecasts, or poor inventory management.

Material quality issues: Unqualified materials may need to be repurchased or reworked, increasing the production cycle. Material quality issues may also lead to product repairs and retesting.

2. Production process issues

Process instability: Instability of the production process, such as inaccurate soldering temperature, patch position deviation, etc., will lead to production interruptions or substandard product quality, thereby affecting production progress.

Equipment failure: Equipment failure or untimely maintenance can cause production lines to stagnate, affecting overall production progress. Old equipment may have a high frequency of failures, further exacerbating delays.

3. Design changes

Frequent changes: Frequent design changes caused by changes in customer needs or design modifications will increase production complexity and adjustment time. This not only affects the production process, but may also lead to reconfiguration of materials and processes.

Changes not handled in a timely manner: Design changes not communicated to the production line in a timely manner or failure to quickly adapt to the new design can lead to production delays and quality problems.

4. Human resource issues

Insufficient operators: Shortage of operators or insufficient skills can lead to inefficient production. Especially during peak production periods, insufficient staff can seriously affect production progress.

Inadequate training: Operators who have not received adequate training or failed to master the operation of new processes and new equipment may lead to reduced production efficiency and quality problems.

5. Quality control issues

Inadequate inspection: Quality inspections that fail to cover all key parameters or unclear inspection standards may result in defective products not being discovered in a timely manner, thereby affecting production progress.

Defects are not handled in time: After quality problems are discovered, there is a lack of effective defect handling processes, which leads to rework and repair, thereby extending the production cycle.

II. Strategies for dealing with production delays

1. Optimize material management

Establish a diversified supply chain: Work with multiple suppliers to reduce the risks caused by a single supplier. Establish a stable supply chain to ensure the continuity and reliability of material supply.

Implement a safety stock strategy: Set a reasonable safety stock level to prevent production interruptions due to material shortages. Regularly evaluate inventory status to ensure sufficient supply of materials.

2. Improve production processes

Optimize production processes: Regularly evaluate and optimize production processes to ensure process stability. Use advanced production technology and equipment to reduce process variation and production interruptions.

Equipment maintenance and update: Regularly maintain and upgrade equipment to ensure the normal operation of equipment. Develop equipment maintenance plans to reduce the impact of equipment failures on production.

3. Effectively manage design changes

Establish a change management process: Develop a strict design change management process to ensure that changes are evaluated and approved. Communicate change information to the production line in a timely manner and make corresponding process adjustments.

Predict demand in advance: Reduce the frequency of design changes through accurate demand forecasting and design planning. Communicate with customers to clarify needs and reduce frequent design adjustments.

4. Improve human resource management

Increase operators: Add temporary or full-time operators during peak production periods to ensure the normal operation of the production line. Develop a reasonable staffing plan to prevent staff shortages from affecting production progress.

Provide training: Provide regular training for operators to improve their skills and process level. The training content should include the operation and quality control requirements of new processes and new equipment.

5. Strengthen quality control

Improve inspection processes: Develop detailed inspection standards and processes to ensure comprehensive coverage of product quality. Regularly check and update inspection processes to improve the effectiveness of quality control.

Rapid defect handling: Establish a fast defect handling process to ensure that problems can be handled quickly after they are discovered. Reduce rework and repair time and improve production efficiency.

Conclusion

Production delays are a common challenge in PCBA processing, but companies can effectively respond to these challenges by optimizing material management, improving production processes, effectively managing design changes, improving human resource management, and strengthening quality control. Continuously improving the production management system and improving production efficiency will help reduce the risk of production delays and ensure the stability of production schedules and customer satisfaction. In a highly competitive market environment, companies should continue to focus on the best practices of production management to cope with changing market demands.

-

Delivery Service

-

Payment Options