- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

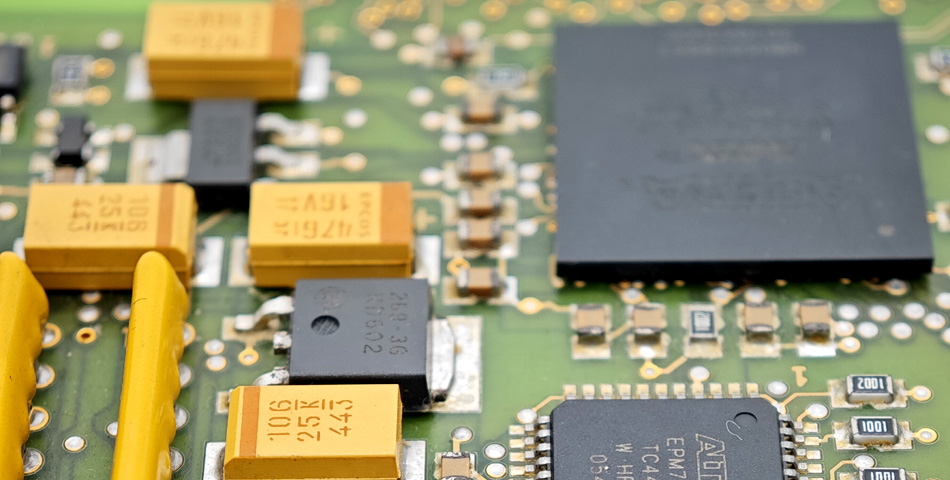

Low yield problem and solution in PCBA processing

2025-05-08

In the process of PCBA (Printed Circuit Board Assembly), low yield is a common production problem. Low yield not only affects production efficiency, but also may lead to delivery delays and customer dissatisfaction. Solving the problem of low yield is crucial to improving the production capacity and economic benefits of the production line. This article will explore the root causes of low yield in PCBA processing and provide corresponding solutions.

I. The root cause of low yield

1. Production equipment problems

Equipment failure: Equipment failure or unstable performance is one of the main reasons for low yield. Equipment failure may cause the production line to stagnate and affect production progress.

Equipment aging: Old equipment may have insufficient performance and cannot meet the requirements of high yield. This will reduce production efficiency and lead to reduced output.

2. Process problems

Process instability: Process instability or improper process parameter settings may lead to unsmooth production and affect output. For example, inconsistent soldering temperature, patch position deviation and other problems.

Process complexity: Complex production processes may require more time and steps, resulting in inefficient production lines and affecting output.

3. Material management issues

Material shortage: Insufficient or insufficient supply of materials may lead to production interruptions and affect production output. Material shortages may be caused by supply chain problems, inaccurate demand forecasts, etc.

Material quality issues: The use of unqualified materials may lead to an increase in defective products in production, which in turn affects production efficiency and output.

4. Human resource issues

Insufficient operators: Insufficient operators on the production line or low skill levels may lead to low production efficiency and affect output.

Insufficient training: Inadequate operator training may lead to operational errors or inefficiency, thereby affecting production output.

5. Quality control issues

Insufficient quality inspection: Incomplete or inadequate quality inspection links may lead to defective products not being discovered in time, affecting production efficiency and output.

Rework and repair: Frequent rework and repair will waste production time and reduce the effective output of the production line.

II. Strategies to solve the problem of low output

1. Improve equipment performance

Equipment maintenance and upgrade: Regularly perform equipment maintenance and maintenance to ensure the normal operation of the equipment. Invest in upgrading production equipment, adopt new technologies and efficient equipment, and improve production capacity and efficiency.

Equipment calibration: Calibrate equipment regularly to ensure that its performance meets production requirements. Reduce errors and downtime in production through precise equipment settings.

2. Optimize process flow

Process standardization: Develop and implement standardized process flow to reduce the impact of human factors on production. Ensure consistency and stability of the production process through standardized operations.

Simplify process: Optimize complex production processes to reduce unnecessary steps and operations. Improve production efficiency and output by simplifying process flow.

3. Improve material management

Optimize material supply chain: Establish a diversified material supply chain to reduce the risks brought by a single supplier. Ensure the stability of material supply and prevent production interruptions due to material shortages.

Strengthen material quality control: Conduct strict quality inspections on materials to ensure that they meet production requirements. Reduce defective products and production delays caused by material quality problems.

4. Improve human resource management

Increase operators: Add temporary or full-time operators during peak production periods to ensure the normal operation of the production line. Improve production efficiency through reasonable allocation of personnel.

Strengthen training: Conduct regular training for operators to improve their skills and work efficiency. The training content should include the operation and quality control requirements of new processes and new equipment.

5. Strengthen quality control

Improve the inspection process: Develop detailed quality inspection standards and processes to ensure that each production link is strictly inspected. Improve production quality and reduce defective products through a complete inspection process.

Reduce rework and repair: Establish a fast and effective defect handling process to reduce the time of rework and repair. Reduce the defective rate in production by improving the process and quality control.

Conclusion

Solving the problem of low yield in PCBA processing requires starting from multiple aspects such as equipment, process, materials, human resources and quality control. By improving equipment performance, optimizing process flow, improving material management, improving human resource management and strengthening quality control, enterprises can effectively increase the output of production lines, improve production efficiency and product quality. In a highly competitive market environment, continuous attention and improvement of the production process will help improve the production capacity and market competitiveness of enterprises.

-

Delivery Service

-

Payment Options