- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to solve equipment failure problems in PCBA processing

2025-05-07

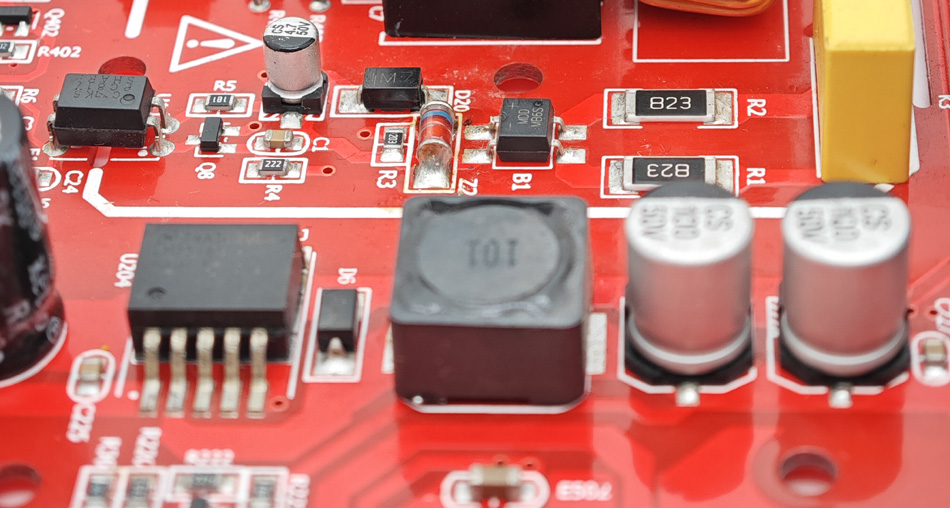

In the process of PCBA (Printed Circuit Board Assembly), equipment failure is an important factor affecting production efficiency and product quality. Equipment failure not only causes production line shutdowns, but may also cause production delays and increased costs. This article will explore how to effectively solve equipment failure problems in PCBA processing and provide some practical strategies and methods to improve the stability and reliability of production equipment.

I. Common equipment failure problems

1. Equipment aging

Wear and damage: As the equipment is used for a longer time, the equipment parts will wear and damage, affecting its normal operation. Common problems include mechanical parts wear, electrical component failure, etc.

Technology obsolescence: Old equipment may not meet the requirements of modern production processes, resulting in low production efficiency and increased failure rates.

2. Improper operation

Improper operation: The operator does not operate the equipment in accordance with the specifications, which may cause equipment failure or damage. For example, incorrect settings or maintenance operations will affect the performance of the equipment.

Insufficient training: The operator's lack of knowledge of equipment operation and maintenance may lead to operating errors and equipment failure.

3. Untimely maintenance

Lack of regular maintenance: If the equipment is not regularly maintained and inspected as required, potential faults may not be discovered and handled in time. For example, the equipment is not cleaned or the worn parts are not replaced.

Delayed maintenance: After the equipment fails, the maintenance response is not timely, which may cause the production line to stop working for a long time and affect the production plan.

4. Environmental factors

Poor environmental conditions: Factors such as temperature, humidity, and dust in the production environment may affect the normal operation of the equipment. For example, too high a temperature may cause the equipment to overheat and affect its performance.

Static electricity interference: Static electricity may interfere with electronic equipment, causing equipment failure or poor production.

II. Strategies to solve equipment failures

1. Regular maintenance and care

Develop a maintenance plan: Develop a detailed equipment maintenance plan that covers regular inspections, cleaning, and care. Regular maintenance can prevent equipment failures and improve the reliability of equipment operation.

Maintenance records: Establish equipment maintenance records to record the content, time, and results of each maintenance and overhaul. Maintenance records can help track the use of equipment and detect potential problems in a timely manner.

2. Improve operator skills

Training and certification: Regular training and skills certification for operators to improve their knowledge of equipment operation and maintenance. The training content should include equipment operating procedures, troubleshooting and maintenance.

Operation specifications: Develop and strictly implement equipment operation specifications to ensure that operators operate equipment in accordance with standards and reduce failures caused by improper operation.

3. Introduce advanced technology

Equipment upgrade: Upgrade or replace old equipment and introduce advanced production technology and equipment. New equipment usually has higher stability and reliability and can improve production efficiency.

Automation control: Introduce automated control systems to improve the automation level of the production process and reduce human operation errors and equipment failures.

4. Environmental control

Optimize the production environment: Control factors such as temperature, humidity and dust in the production environment to ensure that the equipment operates under suitable environmental conditions. For example, use air conditioning systems to maintain stable temperature and humidity.

Static protection: Take static protection measures, such as electrostatic discharge (ESD) control, to reduce the interference of static electricity on equipment. Use static protection mats and anti-static tools to protect equipment and electronic components.

5. Timely troubleshooting

Fault diagnosis: Establish equipment fault diagnosis process to identify and analyze the cause of the fault in time. Through fault diagnosis, the root cause of the problem can be quickly found and appropriate repair measures can be taken.

Maintenance response: Establish a rapid maintenance response mechanism to ensure that the equipment can be repaired as soon as possible after a fault occurs. Rapid repair can reduce production downtime and avoid impact on production plans.

Conclusion

Solving equipment failure problems in PCBA processing is crucial to improving production efficiency and product quality. Through regular maintenance and care, improving operator skills, introducing advanced technologies, optimizing the production environment and handling faults in a timely manner, companies can effectively reduce the occurrence of equipment failures and improve the stability and reliability of equipment. Looking to the future, companies should continue to pay attention to the best practices of equipment management and continuously optimize equipment maintenance strategies to maintain efficient operation of production lines and high product quality.

-

Delivery Service

-

Payment Options