- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Component mounting technology in PCBA processing

2025-02-18

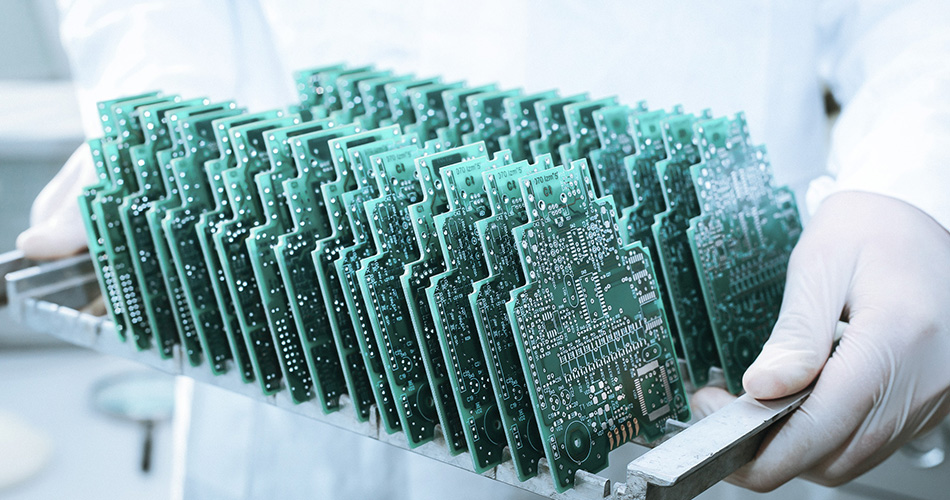

In the process of PCBA (Printed Circuit Board Assembly), component mounting technology is a crucial link. It directly affects the reliability, performance and production efficiency of the product. With the continuous development of electronic products, component mounting technology is also constantly improving to meet the increasingly complex circuit design and improve production efficiency. This article will explore the component mounting technology in PCBA processing, including its importance, main technical methods and future development trends.

I. The importance of component mounting technology

Component mounting technology is the process of accurately placing electronic components on the circuit board in PCBA processing. The quality of this process directly determines the performance, stability and production cost of the product.

1. Improve product reliability

Accurate component mounting can effectively reduce solder joint defects and poor connections, ensuring the stability and reliability of electronic products. The position and connection quality of components are crucial to the normal operation of the circuit. Poor mounting may cause problems such as circuit short circuit, open circuit or signal interference, thereby affecting the overall performance of the product.

2. Improve production efficiency

The use of advanced component mounting technology can significantly improve production efficiency. Automated placement equipment can complete component placement at high speed and high precision, reduce manual operations, and improve the overall production capacity of the production line. In addition, automated equipment can also reduce human errors and reduce production costs.

II. Main placement technology methods

In PCBA processing, commonly used component placement technologies mainly include manual placement, surface mount technology (SMT) and through-hole placement technology (THT).

1. Manual placement

Manual placement is a traditional placement method that is mainly used in small-batch production or prototype development stages. In this method, the operator manually places the components on the circuit board and then fixes them by manual soldering. Although this method is flexible, it has low efficiency and large errors, and is suitable for small-scale production or special situations that require manual intervention.

2. Surface mount technology (SMT)

Surface mount technology (SMT) is the most commonly used placement method in modern PCBA processing. SMT technology directly mounts components on the surface of the circuit board and fixes them by reflow soldering. The advantages of SMT include high-density assembly, short production cycle and low cost. SMT equipment can achieve high-speed and high-precision placement, suitable for large-scale production.

2.1 SMT process flow

The SMT process flow includes the following steps: solder paste printing, component placement, reflow soldering and AOI (automatic optical inspection). Solder paste printing is used to apply solder paste on the pads of the circuit board, and then the components are placed on the solder paste by the placement machine, and finally heated by the reflow soldering equipment to melt the solder paste and fix the components.

3. Through-hole placement technology (THT)

Through-hole placement technology (THT) inserts the pins of the components into the holes on the circuit board and then fixes them by soldering. This technology is often used in situations where high mechanical strength is required or large components are installed on the circuit board. THT is suitable for medium and low-density circuit boards and is usually used in combination with SMT to meet different production needs.

III. Future development trend of component placement technology

With the continuous evolution of electronic products, component placement technology is also constantly developing to cope with higher integration and more complex circuit designs.

1. Automation and intelligence

The future component placement technology will be more automated and intelligent. Advanced automatic placement equipment is equipped with high-precision visual systems and intelligent algorithms, which can adjust placement parameters in real time and optimize the production process. Intelligent equipment can also perform self-diagnosis and maintenance to improve the stability and reliability of the production line.

2. Miniaturization and high density

With the miniaturization trend of electronic products, the component placement technology in PCBA processing also needs to adapt to the requirements of high density and miniaturization. New placement equipment will support smaller components and more complex circuit board designs to meet the needs of future electronic products.

3. Environmental protection and energy saving

Environmental protection and energy saving are important development directions for component placement technology in the future. New placement equipment will use more environmentally friendly materials and processes to reduce waste and energy consumption in the production process, meeting the requirements of green manufacturing.

Summary

In PCBA processing, component placement technology is a key factor in ensuring product quality and production efficiency. By selecting appropriate placement technology, optimizing process flow and paying attention to future development trends, companies can improve the functionality and reliability of products and meet the market demand for high-performance electronic products. Continuous attention to and application of advanced mounting technology will help companies gain advantages in the fierce market competition.

-

Delivery Service

-

Payment Options