- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Environmentally friendly manufacturing solutions in PCBA processing

2025-02-19

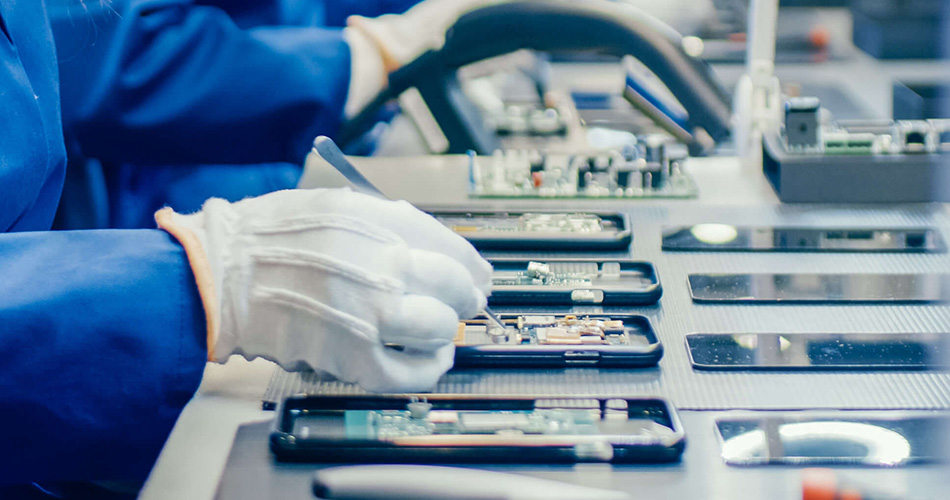

As the world pays more attention to environmental protection, the electronics manufacturing industry is also facing increasingly stringent environmental protection requirements. In PCBA (Printed Circuit Board Assembly) processing, environmentally friendly manufacturing not only helps to reduce the impact of production on the environment, but also enhances the social responsibility and market competitiveness of enterprises. This article will explore environmentally friendly manufacturing solutions in PCBA processing, including reducing waste, improving resource utilization, selecting environmentally friendly materials and implementing clean production technologies.

I. Reducing waste and by-products

Reducing waste and by-products is one of the core strategies of environmentally friendly manufacturing. By optimizing production processes and procedures, the amount of waste generated during the production process can be significantly reduced.

1. Precise process control

In PCBA processing, precise process control can effectively reduce production waste. The use of advanced production equipment and processes, such as high-precision placement machines and reflow soldering machines, can reduce the defect rate during component placement and soldering, thereby reducing the scrap rate. Real-time monitoring of production data and timely adjustment of process parameters can also effectively control the generation of waste.

2. Production process optimization

By optimizing the production process and reducing unnecessary operations and steps, the generation of waste can be further reduced. For example, in the PCB design stage, the reasonable layout of the circuit board and the reduction of useless lines can help reduce material waste in production. Implementing lean production concepts and reducing excess production and inventory can also help reduce waste generation.

II. Improve resource utilization

Improving resource utilization not only helps save costs, but also reduces the burden on the environment. Through the following measures, enterprises can effectively improve resource utilization.

1. Recycling

In PCBA processing, the recycling of waste and by-products is an effective environmental protection measure. For example, waste generated during the production process, such as PCB scraps, can be recycled and reprocessed to produce new PCB boards or other products. This not only reduces the cost of waste treatment, but also reduces the cost of purchasing raw materials.

2. Resource management system

Implementing a resource management system (such as an ERP system) can help companies track and manage resource usage in production in real time. Through data analysis, companies can optimize resource allocation and reduce resource waste. For example, the system can monitor the efficiency of raw material use and adjust procurement plans in time to reduce inventory backlogs and over-purchasing.

III. Select environmentally friendly materials

Selecting environmentally friendly materials is an important way to achieve sustainable manufacturing in PCBA processing. Environmentally friendly materials not only comply with environmental regulations, but also enhance the market competitiveness of products.

1. Environmentally friendly PCB materials

During the PCB manufacturing process, selecting environmentally friendly materials such as lead-free solder and low-pollution PCB substrates can reduce the negative impact on the environment. Lead-free solder can effectively reduce the harm of lead to the environment and health, while low-pollution PCB substrates can reduce the emission of harmful substances in the production process.

2. Green packaging materials

The use of recyclable or biodegradable packaging materials can reduce the impact of packaging waste on the environment. Green packaging materials not only meet environmental protection requirements, but also enhance the green image of the company. For example, using paper or degradable plastics as packaging materials instead of traditional plastic packaging can help reduce environmental pollution.

IV. Implement clean production technology

Clean production technology is an effective means to improve the environmental friendliness of production, and improve the environmental friendliness of the production process by reducing the generation and emission of pollutants.

1. Low emission technology

During PCBA processing, the use of low emission technology can reduce the emission of harmful gases and pollutants. For example, the use of cleaning agents and coatings with low volatile organic compound (VOC) content can effectively reduce the harmful gases generated during the production process. Optimizing the exhaust gas treatment system to ensure that the exhaust gas meets environmental protection standards is also an important clean production measure.

2. Energy-saving technology

The application of energy-saving technology can not only reduce energy consumption, but also reduce production costs. The use of high-efficiency production equipment and energy-saving lighting systems can significantly reduce energy consumption. Implementing energy-saving management measures, such as regularly checking equipment energy efficiency and optimizing energy use in the production process, can also help achieve energy-saving goals.

Summary

In PCBA processing, implementing environmentally friendly manufacturing solutions is an important measure to respond to global environmental trends and enhance corporate competitiveness. From reducing waste, improving resource utilization, selecting environmentally friendly materials to implementing clean production technology, each measure can effectively reduce the impact of production on the environment. Through scientific management and technological innovation, enterprises can not only achieve sustainable development, but also establish a good social image and win market recognition.

-

Delivery Service

-

Payment Options