- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to ensure product quality in PCBA processing

2025-02-17

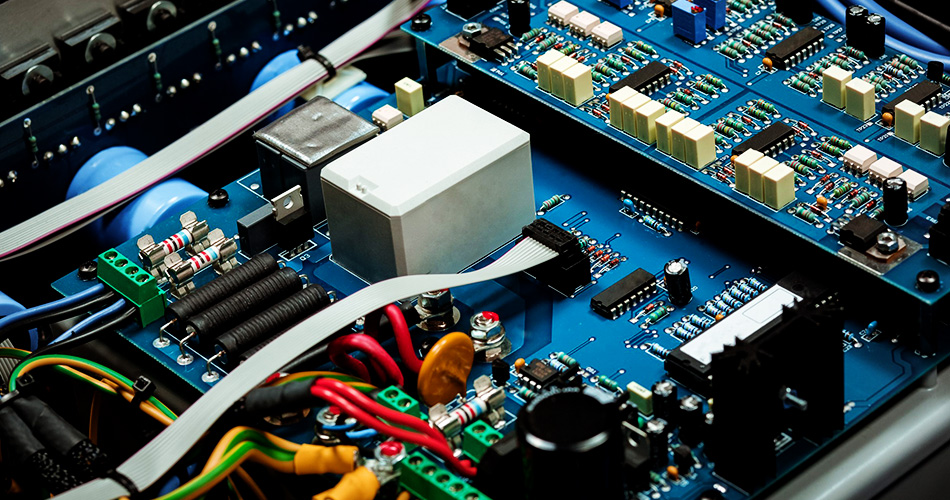

In the electronics manufacturing industry, PCBA (Printed Circuit Board Assembly) processing is a key link in producing high-quality electronic products. Ensuring the quality of PCBA processed products can not only enhance the market competitiveness of enterprises, but also enhance customer trust and satisfaction. This article will explore the key methods and measures to ensure product quality in PCBA processing.

I. Strict component procurement and inspection

The first step to ensure the quality of PCBA processed products is to select high-quality components. The quality of components directly affects the performance and reliability of PCBA finished products. Therefore, in the procurement process, the qualifications of suppliers must be strictly controlled, and all components must be strictly inspected before entering the warehouse.

1. Supplier management

Selecting qualified suppliers is the basis for ensuring the quality of components. Enterprises should establish long-term cooperative relationships with certified suppliers and conduct regular audits on them to ensure that the components they supply meet quality standards. Establishing cooperative relationships with multiple suppliers can disperse risks to a certain extent and avoid production being affected by problems with a single supplier.

2. Warehouse inspection

Warehouse inspection is an indispensable part of PCBA processing. All purchased components must be inspected before entering the warehouse, including electrical performance testing, appearance inspection and packaging inspection. For key components, enterprises should consider using advanced testing equipment, such as X-ray detectors, to ensure that the internal structure of the components is defect-free.

II. Optimize PCBA processing technology

In the process of PCBA processing, optimizing the process flow is the key to ensuring product quality. The use of advanced processing technology and equipment can greatly reduce the defect rate in the production process and improve the consistency and reliability of products.

1. Optimization of surface mount technology (SMT)

Surface mount technology (SMT) is one of the core processes of PCBA processing. In the SMT process, the quality of solder paste printing and reflow soldering directly determines the connection reliability of components. Enterprises should use high-precision solder paste printing equipment to ensure uniform distribution of solder paste; at the same time, reflow soldering equipment should be equipped with a multi-zone temperature control system to accurately control the temperature curve and avoid the generation of solder joint defects.

2. Strict process control

In the process of PCBA processing, strict process control is the key to ensuring quality. Enterprises should formulate detailed process specifications and operating standards, and conduct strict training for operators to ensure that each process is carried out in accordance with the standards. In addition, enterprises should also use tools such as SPC (statistical process control) to monitor possible deviations in the production process in real time, and make timely adjustments to prevent quality problems.

III. Comprehensive quality inspection and control

In order to ensure the quality of the final product processed by PCBA, comprehensive quality inspection and control must be carried out during the production process. Through advanced testing equipment and technical means, enterprises can detect and correct quality problems in production as early as possible to ensure the reliability of shipped products.

1. Automatic optical inspection (AOI)

Automatic optical inspection (AOI) is a non-contact inspection technology that is widely used in quality control of PCBA processing. AOI equipment can quickly detect the position of components, solder joint quality, component polarity, etc. on the PCB to ensure that each circuit board meets the design requirements. For complex PCBs, enterprises should give priority to high-resolution AOI equipment to improve detection accuracy.

2. Functional testing

Functional testing is the last line of defense to ensure the quality of PCBA finished products. By simulating the actual use environment and performing functional testing on PCBA, it is possible to verify whether the circuit board works normally under specific conditions. Enterprises should design comprehensive test solutions based on different application scenarios of the product to cover all factors that may affect product performance.

IV. Continuous quality improvement

In PCBA processing, continuous quality improvement is the key to the company's long-term competitiveness. Through continuous quality analysis and improvement measures, companies can gradually improve product quality and meet the market demand for high-quality electronic products.

1. Quality data analysis

By systematically analyzing the quality data in the production process, companies can discover potential quality problems and improvement opportunities. With the help of big data analysis tools, companies can identify key factors that affect product quality and develop targeted improvement measures. For example, by analyzing the data of soldering defects, companies can adjust soldering process parameters and improve soldering quality.

2. PDCA cycle

The PDCA (Plan-Do-Check-Act) cycle is a common tool for quality management. Companies should apply the PDCA cycle to every link of PCBA processing, formulate improvement plans, implement improvement measures, regularly check the improvement effects, and continuously optimize the process flow. Through this continuous improvement process, enterprises can gradually reduce quality problems and improve product reliability and customer satisfaction.

Summary

Ensuring product quality in PCBA processing is the basis for the survival and development of electronic manufacturing companies. From the procurement and inspection of components, optimization of processing technology, comprehensive quality inspection and control, to continuous quality improvement, every link is crucial. By fully implementing these measures, enterprises can effectively improve the quality of PCBA processed products and win a dominant position in market competition.

-

Delivery Service

-

Payment Options