- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to achieve product customization through PCBA processing

2025-02-15

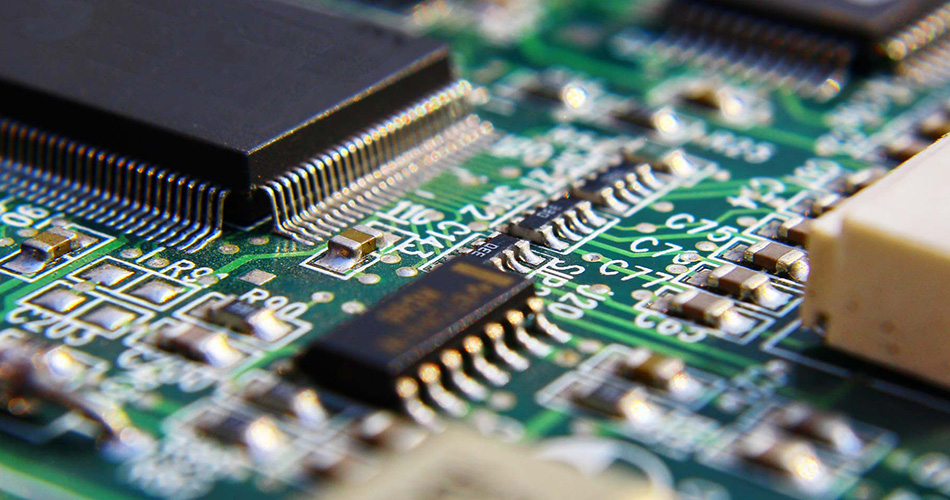

With the development of science and technology and the diversification of consumer needs, product customization has gradually become a major trend in the electronics manufacturing industry. PCBA (Printed Circuit Board Assembly) processing is a key link in the manufacturing of electronic products. How to achieve high customization of products through it has become the focus of many companies. This article will explore how to achieve product customization through PCBA processing, improve product competitiveness, and meet the diversified needs of the market.

I. The importance of product customization through PCBA processing

In today's highly competitive market, standardized products have been difficult to meet the personalized needs of consumers. Product customization through PCBA processing can not only provide products that better meet customer needs, but also help companies stand out in the market and establish differentiated competitive advantages.

1. Meet personalized needs

With the continuous improvement of consumer requirements for the functions and appearance of electronic products, customization has become a new consumer trend. Through PCBA processing, companies can flexibly adjust the design of circuit boards, the selection of components, and the configuration of functional modules according to the specific requirements of customers, so as to produce customized products that meet customer needs.

2. Increase product added value

Customized products usually have higher added value and can bring higher profits to companies. Through PCBA processing to achieve product customization, enterprises can provide differentiated solutions according to the needs of different customers, thereby enhancing the market competitiveness and added value of products.

II. Key factors for PCBA processing to achieve product customization

To achieve product customization in PCBA processing, it is necessary to comprehensively consider multiple key factors, including circuit design, material selection, production process and production management.

1. Flexibility of circuit design

Circuit design is the basis for achieving customized PCBA processing. In order to meet the needs of different customers, enterprises need to have flexible circuit design capabilities. This means that in the design stage, it is necessary to fully consider the combination and configuration of different functional modules so that they can be quickly adjusted and optimized according to customer needs in the subsequent processing process.

2. Diversity of material selection

Material selection also plays a vital role in PCBA processing customization. Different application scenarios and customer needs may put forward different requirements on the materials of circuit boards, the performance of components, etc. Therefore, enterprises need to establish a diversified material supply chain to ensure that they can provide materials that meet customer requirements in a short time, so as to achieve product customization.

3. Flexibility of production process

In PCBA processing, the flexibility of production process is an important guarantee for achieving customization. Enterprises need to introduce flexible production technology and automation equipment on the production line to achieve rapid switching and adjustment between different products. At the same time, by optimizing the process flow and reducing switching time and resource waste, production efficiency can be effectively improved to meet the requirements of customized production.

4. Efficient production management

Efficient production management is also a key factor in achieving customized PCBA processing. Enterprises need to use information management systems to monitor and coordinate various links such as orders, production, and materials in real time to ensure that customized orders can be completed on time and in quality. In addition, the refinement of production management can also help enterprises reduce costs and improve production efficiency, thereby better meeting customers' customized needs.

III. Application examples of PCBA processing to achieve product customization

In actual applications, customization of PCBA processing has been widely used in many industries. For example, the demand for customized products in the fields of smart home, medical equipment, automotive electronics, etc. is increasing. PCBA processing companies have successfully achieved customized production of products through flexible production methods and efficient management systems.

1. Smart home products

The diversified demand for smart home products has brought new opportunities for the customization of PCBA processing. Through PCBA processing, companies can customize smart home control boards with different functions according to customer needs, such as lighting control, security systems, temperature control, etc., so as to provide customers with personalized smart home solutions.

2. Medical equipment

In the field of medical equipment, customization needs are more prominent. Through PCBA processing, companies can customize dedicated circuit boards for different medical equipment to meet the needs of specific functions, such as patient monitoring, diagnostic instruments, etc. This highly customized PCBA processing not only improves the reliability of medical equipment, but also enhances its competitiveness in the market.

Summary

Product customization through PCBA processing is an important way for electronic manufacturing companies to enhance their market competitiveness. Through flexible circuit design, diverse material selection, flexible production process and efficient production management, companies can meet the personalized needs of customers and provide customized products with high added value. In the future development, the customization of PCBA processing will further promote the innovation and progress of the electronic manufacturing industry and help companies occupy a favorable position in the fierce market competition.

-

Delivery Service

-

Payment Options