- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

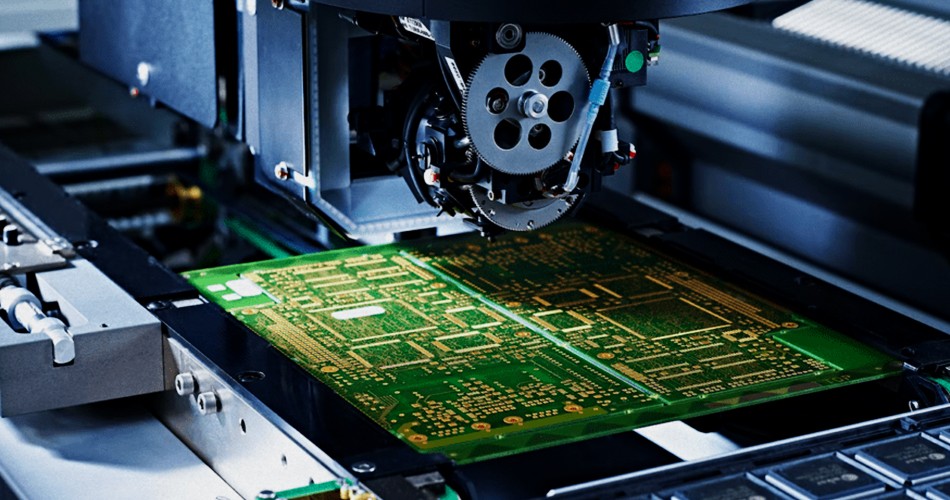

Production environment control in PCBA processing

2025-02-06

During the process of PCBA processing (Printed Circuit Board Assembly), the control of the production environment has a vital impact on product quality and production efficiency. A good production environment can ensure the quality of electronic components and soldering, reduce the defect rate, and improve the reliability and stability of products. This article will discuss in detail how to effectively control the production environment in PCBA processing.

I. Temperature and humidity control

1. Temperature control

Temperature is one of the key factors affecting the quality of PCBA processing. Too high or too low temperature will affect the quality of components and soldering.

Constant temperature environment: Maintain a constant temperature environment in the production workshop, and the temperature is usually recommended to be between 20-25℃.

Temperature monitoring: Use a temperature sensor to monitor the temperature of the production environment in real time to ensure that the temperature is within the set range.

Air conditioning system: Install an efficient air conditioning system to adjust and maintain the temperature in the workshop.

2. Humidity control

Humidity has a significant impact on soldering and component storage in PCBA processing. Excessive humidity will cause solder joint oxidation and component moisture, while too low humidity will cause static electricity problems.

Constant humidity environment: Control the humidity of the production workshop between 40%-60% to ensure that the environmental humidity is moderate.

Humidity monitoring: Use humidity sensors to monitor humidity changes in real time and adjust humidification or dehumidification equipment in time.

Dehumidification equipment: Install a dehumidifier or humidifier to adjust the humidity as needed to prevent the environment from being too dry or humid.

II. Anti-static measures

1. Static electricity hazards

Static electricity can damage electronic components, resulting in reduced product quality and increased failure rate. Therefore, anti-static measures are an indispensable part of PCBA processing.

Anti-static floor: Lay anti-static floor in the production workshop to reduce static electricity accumulation.

Anti-static workbench: Use anti-static materials to make the workbench to ensure that no static electricity is generated during operation.

Anti-static wristband: Operators wear anti-static wristbands and ground to eliminate human static electricity.

2. Static electricity monitoring

Establish an electrostatic monitoring system to detect the static electricity in the workshop in real time and take timely measures to eliminate static electricity.

Static electricity tester: Use an electrostatic tester to regularly detect the static electricity voltage in the workshop to ensure that it is within a safe range.

Static eliminator: Install a static eliminator to eliminate static electricity through ion wind and other methods to maintain the static balance of the environment.

III. Air quality control

1. Air purification

Dust and pollutants in the air will affect the quality of PCBA processing, so it is very important to keep the air in the workshop clean.

Air filtration system: Install a high-efficiency air filtration system to filter out dust and particles in the air.

Regular cleaning: Clean the production workshop regularly to reduce the accumulation of dust and pollutants.

Clean room: Set up a clean room in key process links to ensure a high-cleanliness production environment.

2. Harmful gas control

Some production processes will produce harmful gases, which must be controlled and discharged in time to ensure the health of operators and the safety of products.

Exhaust system: Install an efficient exhaust system to promptly discharge harmful gases generated during the production process.

Gas detector: Use a gas detector to monitor the concentration of harmful gases in the workshop to ensure that it is within a safe range.

Ventilation equipment: Maintain good ventilation conditions, discharge harmful gases in time, and ensure air circulation.

IV. Lighting and noise control

1. Lighting control

Good lighting conditions contribute to the efficiency of operators and the accuracy of product inspection.

Natural light: Make full use of natural light to reduce eye fatigue and improve operating efficiency.

Artificial lighting: In the case of insufficient light, artificial lighting is used to maintain a uniform and bright working environment.

Shadowless lamp: In the delicate operation and inspection process, use shadowless lamp to ensure uniform light without shadow interference.

2. Noise control

Excessive noise will affect the concentration and work efficiency of operators, so it is necessary to effectively control the noise level in the production workshop.

Sound insulation measures: Take sound insulation measures for noise-generating equipment, such as installing sound insulation covers and using sound insulation materials.

Noise monitoring: Use noise monitoring equipment to monitor the noise level in the workshop in real time to ensure that it is within a reasonable range.

Earplugs: Provide operators with anti-noise earplugs to reduce the interference of noise on work.

Conclusion

In PCBA processing, the control of the production environment is an important factor in ensuring product quality and production efficiency. By effectively controlling temperature and humidity, taking anti-static measures, maintaining air quality, and optimizing the lighting and noise environment, companies can create an efficient and safe production environment and improve the overall level of PCBA processing. In the future, with the continuous advancement of technology, production environment control will become more intelligent and refined, providing a solid guarantee for the development of the PCBA processing industry.

-

Delivery Service

-

Payment Options