- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

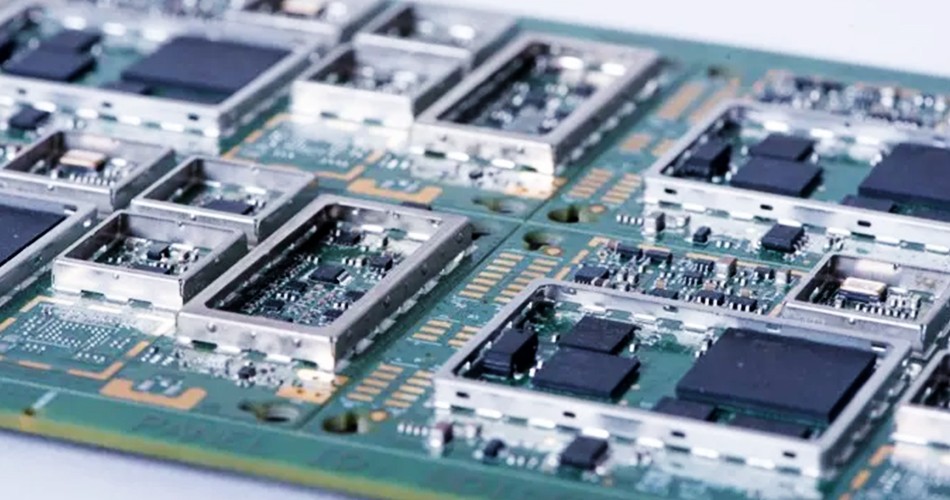

High reliability design in PCBA processing

2025-02-05

In PCBA processing (Printed Circuit Board Assembly), high reliability design is the key to ensure product performance and life. Especially in demanding applications such as aerospace, medical equipment and automotive electronics, high reliability design can significantly reduce failure rates and improve product stability and durability. This article will explore the core elements and methods of achieving high reliability design in PCBA processing.

I. Optimize circuit design

1. Reduce signal interference

The first step in high reliability design is to optimize circuit design and reduce signal interference.

Reasonable wiring: Use reasonable wiring schemes to avoid long lines and cross wiring to reduce signal interference.

Shielding measures: Use shielding measures on key signal lines, such as adding metal shielding layers to prevent external interference.

Ground design: Use good ground design to ensure stable signal transmission and reduce noise interference.

2. Choose the right components

Choosing high-quality and applicable components is essential to ensure the reliability of PCBA.

Component selection: Use electronic components with high reliability, such as certified components and brands, to avoid system problems caused by component failure.

Adaptation specifications: Ensure that the working specifications of the components match the circuit requirements to avoid component failure due to overload or overtemperature.

Reliability test: Perform reliability tests on components, such as high temperature and high humidity tests, to ensure their stability in extreme environments.

II. Design redundancy and protection

1. Redundant design

Redundant design is an important strategy to improve system reliability.

Redundant circuit: Design redundant circuits and backup systems to ensure that the backup system can continue to work when the main system fails.

Dual design: Use dual design on key functional modules to improve the fault tolerance of the system.

2. Overcurrent and overvoltage protection

Effective protection measures can prevent failures caused by abnormal current or voltage.

Protection circuit: Add overcurrent and overvoltage protection circuits, such as fuses, TVS diodes, etc., to the circuit design to prevent electrical abnormalities from damaging components.

Voltage regulator: Use a voltage regulator or power filter to ensure the stability of the circuit power supply and avoid the impact of voltage fluctuations on the circuit.

III. Implement thermal management

1. Thermal design

Thermal management design helps control the temperature on the circuit board and prevent failures caused by overheating.

Heat dissipation design: Design effective heat dissipation solutions, such as using heat sinks, thermal conductive materials, etc., to help dissipate heat and cool down.

Thermal analysis: Use thermal analysis tools to simulate the thermal distribution of the circuit board, optimize thermal design, and ensure stability in high temperature environments.

2. Environmental testing

Perform environmental testing during the design phase to verify reliability in high and low temperature environments.

Environmental simulation: Perform high temperature, high humidity and vibration tests on PCBA to evaluate its performance in extreme environments.

Reliability testing: Perform long-term stability tests, such as accelerated aging tests, to predict the life and reliability of PCBA in actual use.

IV. Ensure manufacturing process control

1. Quality control

Quality control in the manufacturing process is a key link to ensure the reliability of PCBA.

Process monitoring: Real-time monitoring of key parameters in the production process, such as soldering temperature, component placement accuracy, etc., to ensure the stability of the production process.

Defect detection: Use automated inspection equipment, such as AOI (automatic optical inspection) systems, to detect defects in production and ensure product quality.

2. Process verification

Verify and optimize the production process to ensure that it meets design requirements and reliability standards.

Process verification: Verify and test the manufacturing process to ensure that the reliability of the product is not affected during the production process.

Process optimization: Continuously optimize the production process, improve production efficiency and product quality, and ensure the high reliability of PCBA in actual applications.

V. Implement system-level testing

1. Functional testing

Perform comprehensive functional testing before product delivery to ensure its reliability in actual applications.

Functional verification: Perform comprehensive functional verification tests on PCBA to ensure that its various functions work properly.

Environmental adaptability testing: Perform environmental adaptability testing to evaluate the performance of PCBA under different environmental conditions.

2. Fault analysis

In-depth analysis of the faults found, find out the root cause of the problem, and make improvements.

Fault analysis: Use fault analysis tools, such as X-ray inspection and electron microscopes, to analyze the cause of the fault.

Improvement measures: According to the results of fault analysis, take corresponding improvement measures to improve the reliability and stability of the product.

Conclusion

In PCBA processing, achieving high reliability design is the key to ensuring product performance and stability. By optimizing circuit design, designing redundancy and protection, implementing thermal management, ensuring manufacturing process control and system-level testing, companies can effectively improve the reliability of PCBA. High-reliability PCBA can not only operate stably in various application environments, but also improve the market competitiveness of products. With the continuous development of technology, high-reliability design will play an increasingly important role in PCBA processing.

-

Delivery Service

-

Payment Options