- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

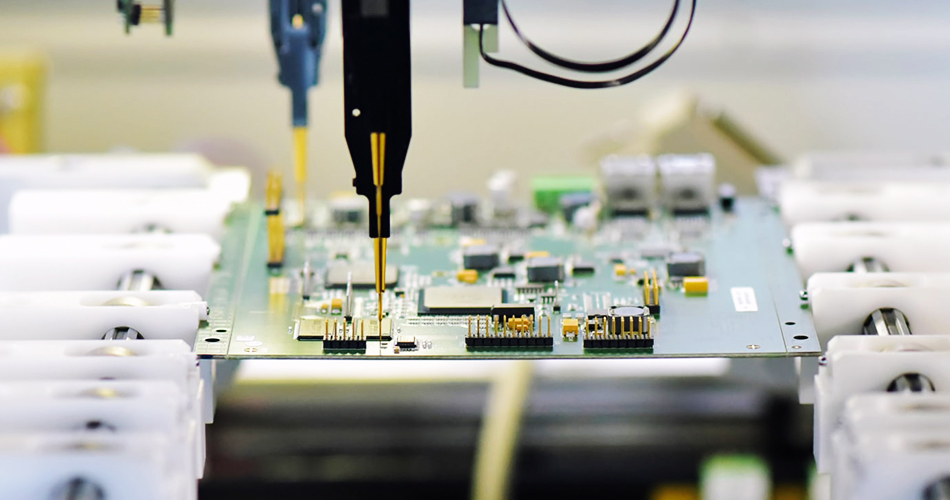

Advanced detection technology in PCBA processing

2025-02-07

In PCBA processing (Printed Circuit Board Assembly), detection technology is crucial to ensure product quality and performance. With the continuous advancement of technology, more and more advanced detection technologies are being applied to the PCBA processing process to improve detection accuracy, efficiency and reliability. This article will explore several common advanced detection technologies and their applications in PCBA processing.

I. Automatic optical inspection (AOI)

1. Overview of AOI technology

Automatic optical inspection (AOI) is a technology that uses a visual system to automatically detect circuit boards and is widely used in PCBA processing.

Working principle: The AOI system scans the circuit board through a high-resolution camera, captures the image and compares it with the preset standard to identify defects and bad points.

Detection content: AOI can detect problems such as solder joint quality, component location, missing components and short circuits.

2. Advantages of AOI

AOI technology is fast, accurate and contactless, which can significantly improve detection efficiency.

Improve production efficiency: Automated detection reduces the time of manual detection and improves production efficiency.

High accuracy: High-resolution images and intelligent algorithms can accurately identify tiny defects and reduce false detection rates.

II. X-ray detection (X-Ray)

1. Overview of X-ray technology

X-ray detection (X-Ray) is a detection technology that uses X-rays to see through the internal structure of the circuit board, which is suitable for complex PCBA detection tasks.

Working principle: X-rays penetrate the circuit board to form an image of the internal structure, and internal defects such as poor soldering and short circuits are detected by analyzing the image.

Application range: X-ray detection is particularly suitable for the detection of surface mount components such as BGA (Ball Grid Array) and CSP (Chip Scale Package).

2. Advantages of X-ray detection

X-ray detection technology can provide in-depth and detailed internal inspections and is suitable for detecting hidden defects.

Revealing hidden defects: It can detect invisible internal defects such as cold solder joints and tin beads to ensure the overall reliability of the product.

Non-destructive testing: Non-destructive testing of circuit boards does not affect the integrity of the product.

III. Infrared thermal imaging detection

1. Overview of infrared thermal imaging technology

Infrared thermal imaging detection uses infrared cameras to capture the temperature distribution image of the circuit board to detect possible overheating or thermal failure problems.

Working principle: The infrared camera captures the infrared radiation on the surface of the circuit board, converts it into a temperature image, and identifies anomalies by analyzing the thermal image.

Application scope: Suitable for detecting thermal anomalies, overheating areas and power management problems in circuit boards.

2. Advantages of infrared thermal imaging detection

Infrared thermal imaging technology can monitor the temperature changes of the circuit board in real time and provide valuable fault diagnosis information.

Real-time detection: It can monitor the temperature of the circuit board in real time and detect potential overheating problems in time.

Non-contact detection: It uses non-contact detection to avoid physical interference with the circuit board.

IV. Electrical testing (ICT)

1. Overview of ICT technology

Electrical testing (In-Circuit Testing, ICT) is a test technology for detecting the functionality and connectivity of circuit boards. The circuit board is tested through electrical signals.

Working principle: ICT uses test probes to connect to the test points of the circuit board, applies electrical signals and measures the response to check the electrical performance and connectivity of the circuit.

Detection content: Short circuit, open circuit, component value mismatch and soldering problems of the circuit board can be detected.

2. Advantages of ICT

ICT technology can perform comprehensive electrical performance tests during the production process to ensure the functionality and reliability of the circuit board.

Comprehensive test: Comprehensively test the various electrical parameters of the circuit board to ensure the functionality of the product.

High efficiency: The automated test process improves the test efficiency and reduces manual intervention.

V. Functional test

1. Overview of functional test

Functional test is a test of PCBA under actual working conditions to ensure that its various functions meet the design requirements.

Working principle: Put the PCBA in a simulated working environment and verify its functions and performance by executing the preset functional test program.

Application scope: Applicable to testing the actual working status and functions of PCBA and evaluating its performance in actual applications.

2. Advantages of functional test

Functional test can simulate real working conditions and provide test results closest to the actual use environment.

Real environment test: Test under real working conditions to ensure the performance of PCBA in actual use.

Problem discovery: It can discover functional problems and ensure the reliability and stability of the product.

Conclusion

In PCBA processing, the use of advanced detection technology is an important means to ensure product quality and performance. By introducing technologies such as automatic optical inspection (AOI), X-ray inspection, infrared thermal imaging inspection, electrical testing (ICT) and functional testing, companies can improve detection accuracy, efficiency and reliability. In the future, with the continuous advancement of technology, these detection technologies will continue to develop and further improve the overall quality and production efficiency of PCBA processing.

-

Delivery Service

-

Payment Options