- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does the functional testing of PCBA factories improve product reliability?

2025-08-07

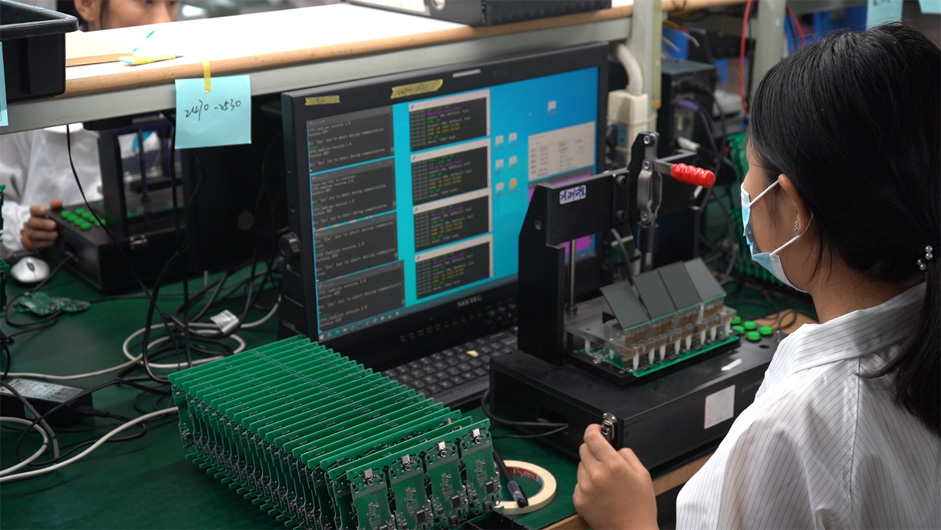

In the PCBA process, functional testing is an important part to ensure that the circuit board operates normally and meets the design requirements. The role of functional testing is not only to test the stability of the circuit board under various conditions, but also the key to improving product reliability and customer satisfaction. This article will explore how the functional testing of PCBA factories can help improve product reliability.

1. The importance of functional testing in PCBA processing

Ensure the normal performance of the circuit board

Functional testing can ensure that each PCBA can work normally according to the design specifications after production. This link is crucial, especially in the context of increasingly complex electronic products. Functional testing can identify potential problems in the circuit board and ensure that it is repaired or replaced before leaving the factory.

Improve product reliability

Through functional testing, the factory can find weak links that may cause product failures under extreme conditions, ensuring the stable operation of the product in harsh environments. Products with high reliability not only reduce the cost of rework and after-sales service, but also win the trust of customers and enhance brand reputation.

2. Types and steps of functional testing

Basic functional testing

Basic functional testing is designed to detect the basic functions of PCBA, such as voltage, current and signal path. This type of test can help engineers quickly find simple short circuits, open circuits or other hardware failures.

Specific functional testing

PCBA factories usually perform specific functional tests for different product application requirements. For example, for communication equipment, the test will involve the stability of signal transmission and data processing capabilities; for household appliances, the test may include the accuracy and safety of the control circuit.

High temperature testing and pressure testing

In some cases, functional testing also includes testing under extreme temperature or high pressure environments. This type of test can simulate the actual use environment of the product and help verify the reliability of PCBA under extreme conditions.

3. How does PCBA factory functional testing improve product reliability

Identify early faults

Functional testing can detect early faults that may cause product failure at the end of the production line, such as circuit mismatch, poor component soldering and other problems. If these faults are identified and repaired before leaving the factory, they can avoid problems during customer use, thereby reducing after-sales problems.

Improve long-term stability

By simulating long-term operation, functional testing can detect whether PCBA will have problems under long-term use. Such tests help confirm the durability and long-term stability of the product, especially for equipment that needs to work for a long time, such as industrial control systems or communication infrastructure.

Reduce the rework rate

Rework not only increases production costs, but also affects customer experience. Functional testing ensures that each product meets the design requirements by fully checking the functions of the PCBA before leaving the factory, thereby effectively reducing unnecessary rework and improving the production efficiency of the factory.

4. Advantages of automated functional testing

Improve test efficiency

In mass production, manual functional testing obviously cannot meet efficiency requirements. The automated functional testing system can test multiple PCBAs at the same time with higher accuracy and faster speed, which can greatly improve the efficiency of testing.

Improve test accuracy

Automated functional testing can detect potential problems faster and more accurately than manual testing through high-precision equipment and programmed testing processes, thereby improving product reliability.

Reduce labor costs

The use of automated testing equipment can not only reduce the errors of manual operation, but also reduce labor costs. For PCBA processing plants, this can not only improve the quality of testing, but also improve the economic benefits of the entire production line.

5. Combination of continuous improvement and functional testing

Continuously optimize the testing process

Functional testing is not static. With the upgrading of products and the development of technology, PCBA factories should continuously optimize the testing process to ensure that the test can cover all important functions of the product. Continuously improving the testing process can not only improve product quality, but also reduce testing costs.

Introducing customer feedback

Customer feedback is an important source for improving functional testing. By analyzing the problems encountered by customers in using the product, the factory can further adjust the test content to ensure that these problems can be identified and solved in future tests, thereby improving the reliability of the product.

Conclusion

Functional testing is a crucial link in PCBA processing. It not only ensures that the product functions normally when it leaves the factory, but also improves the long-term stability and reliability of the product. Through basic functional testing, automated testing, and testing that simulates extreme environments, PCBA factories can significantly reduce the defective rate, reduce rework, and improve customer satisfaction. With the advancement of technology and the optimization of factory management, functional testing will continue to play a key role in product quality assurance and provide strong support for the sustainable development of the PCBA processing industry.

-

Delivery Service

-

Payment Options