- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does the quality assurance system of the PCBA factory ensure the long-term stability of the product?

2025-08-06

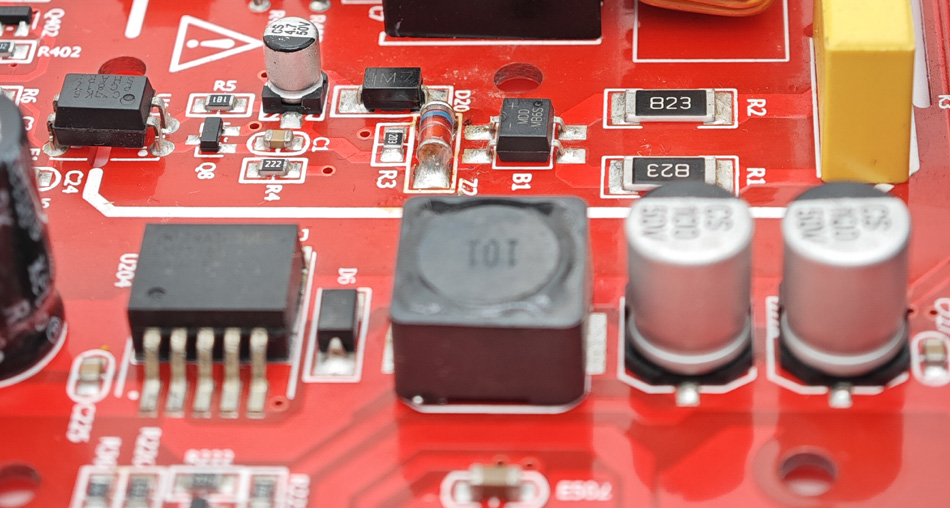

In the electronics manufacturing industry, PCBA(printed circuit board assembly) processing is a crucial link. With the rapid development of science and technology and the intensification of market competition, customers' requirements for product quality are increasing. In order to ensure the long-term stability of products, PCBA factories must establish a complete quality assurance system. This article will explore how the quality assurance system of the PCBA factory can effectively guarantee the quality and stability of products.

1. The basic composition of the quality assurance system

Quality policy and objectives

An effective quality assurance system must first clarify the quality policy and quality objectives. These policies and objectives provide a clear direction for the company so that all employees can work towards common quality standards. PCBA factories ensure that quality management runs through the entire production process by setting specific quality goals, such as reducing the defective rate and improving customer satisfaction.

Quality management process

The quality assurance system of the PCBA factory should include a complete quality management process from raw material procurement, production process control to finished product inspection. Standards and procedures need to be set for each link to ensure the standardization and traceability of the production process. Through strict process control, the factory can promptly detect and correct potential problems and reduce the risk of product defects.

2. Quality control of key links

Raw material control

During the PCBA processing process, the quality of raw materials directly affects the stability of the final product. The factory should establish a cooperative relationship with a reputable supplier and conduct strict warehousing inspection on raw materials to ensure that they meet relevant standards. Through effective control of materials, the factory can lay a solid foundation for subsequent production.

Production process monitoring

During the production process, PCBA factories should implement real-time monitoring and data collection to ensure the stability of various production parameters. Using automated equipment and monitoring systems, factories can track the production process in real time and adjust parameters that do not meet standards in a timely manner, thereby reducing human errors and fluctuations.

Finished product inspection

Finished product inspection is a vital part of the quality assurance system. PCBA factories should establish complete inspection standards and processes, and conduct strict functional testing, appearance inspection and reliability testing on finished products. Through comprehensive testing, the factory can promptly discover and eliminate unqualified products to ensure product quality and stability.

3. Continuous improvement and customer feedback

Continuous improvement mechanism

PCBA factories should establish a continuous improvement mechanism and regularly evaluate and optimize the quality management system. Through data analysis and problem summary, the factory can identify potential quality risks and take targeted improvement measures. This continuous optimization can effectively improve the long-term stability of the product.

Utilization of customer feedback

Customer feedback information is an important basis for improving product quality. PCBA factories should attach importance to customer opinions and suggestions, regularly collect and analyze customer feedback, and adjust production and management strategies in a timely manner. By maintaining good communication with customers, the factory can understand changes in market demand and respond quickly.

4. Construction of quality culture

Cultivation of quality awareness

In PCBA factories, quality is not only the responsibility of the quality assurance department, but also the common mission of all employees. Through training and publicity, the factory can establish quality awareness among employees so that every employee can consciously abide by quality standards and processes, thus forming a good quality culture.

Incentive mechanism

Establishing an incentive mechanism is also an important means to improve quality culture. Factories can motivate employees to actively participate in quality management and encourage them to put forward improvement opinions and suggestions by setting up quality awards and performance appraisals. Through these means, the factory can effectively improve the overall quality level.

Conclusion

The quality assurance system of the PCBA factory is an important guarantee to ensure the long-term stability of products. Through clear quality policies, strict production control, continuous improvement and a good quality culture, the factory can remain invincible in the fierce market competition. In the future, as the market's quality requirements continue to increase, PCBA factories need to continue to strengthen the construction of quality assurance systems to ensure product quality and stability in order to meet customer needs and win the trust of the market.

-

Delivery Service

-

Payment Options