- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How do PCBA factories cope with the challenges of mounting complex components?

2025-08-02

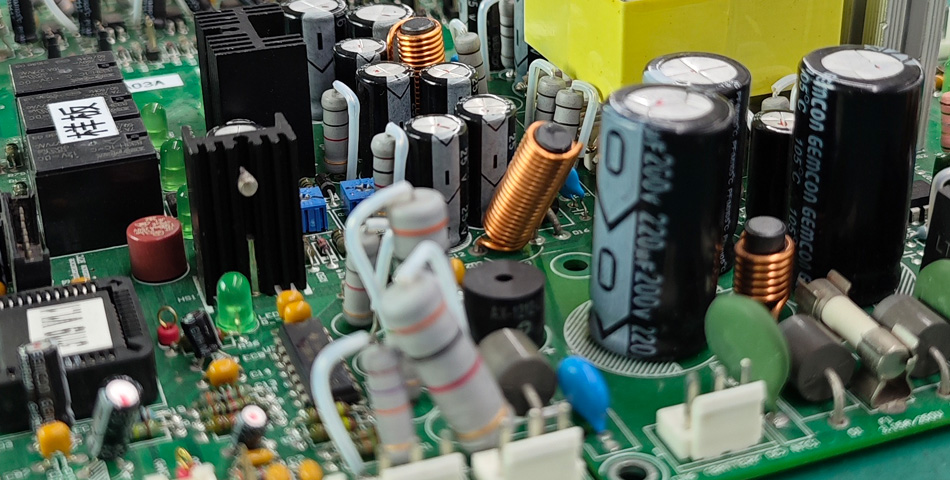

In the manufacturing process of modern electronic products, PCBA processing (Printed Circuit Board Assembly) has become a crucial link. With the development of technology, the functions of electronic components have become more powerful, and the size has become smaller and smaller, which has brought challenges to the mounting of complex components. How to deal with these challenges has become a problem that PCBA factories must solve. This article will explore the strategies of PCBA factories to cope with the challenges of mounting complex components.

1. Understand the characteristics of complex components

Complex components usually refer to components with high functional integration, small size and variable shapes, such as BGA (Ball Grid Array), QFN (Quad Flat No-lead) and CSP (Chip Size Package). These components have high mounting accuracy requirements, and any minor errors may cause functional failure. Therefore, when mounting these complex components, PCBA factories must fully understand their characteristics to ensure processing quality.

2. Introduce advanced equipment

Automated mounting equipment

In order to improve the mounting accuracy of complex components, PCBA factories need to introduce advanced automated mounting equipment. These devices are usually equipped with high-precision visual recognition systems and mounting technology, which can complete high-precision component mounting in a short time. The use of automated equipment not only improves production efficiency, but also reduces the errors caused by human operation.

Multifunctional soldering machine

For the soldering of complex components, traditional soldering methods may not meet the requirements. PCBA factories can introduce multifunctional soldering machines that support multiple soldering methods such as reflow soldering, wave soldering, etc. to meet the soldering needs of different components. By choosing the appropriate soldering method, the soldering quality can be ensured and the reliability of the product can be improved.

3. Improve the process flow

Strict process control

PCBA factories need to establish a complete set of process flows and strictly control each link. Before mounting components, the factory can inspect and classify components to ensure that only components that meet the standards can enter the production line. In addition, process parameters such as temperature, pressure and time need to be precisely controlled to prevent mounting problems caused by improper process.

Continuous process optimization

With the continuous emergence of new technologies and new materials, PCBA factories need to regularly evaluate and optimize production processes. Through the analysis of production data, potential problems can be found and process parameters can be adjusted in time to improve the quality of placement and production efficiency.

4. Strengthen employee training

The operators of PCBA factories are the key to ensuring the quality of complex component placement. Regular training of employees to make them aware of the latest production equipment, process flow and quality standards will help improve the overall production level. Especially when dealing with high-precision components, the technical ability and experience of employees are particularly important.

5. Quality monitoring and feedback

Real-time monitoring system

In order to ensure the placement quality of complex components, PCBA factories should establish a real-time monitoring system to comprehensively monitor the production process. Through data collection and analysis, problems in production can be discovered and corrected in time to reduce the defect rate.

Feedback mechanism

It is also very important to establish a sound feedback mechanism. Problems that arise during the production process should be recorded and fed back to the relevant departments in a timely manner for improvement. This feedback can not only solve current problems, but also provide reference for future production, thereby improving the overall production quality.

Conclusion

To cope with the challenges of mounting complex components, PCBA factories need to start from multiple aspects, including introducing advanced equipment, improving process flow, strengthening employee training, and establishing real-time monitoring and feedback mechanisms. Only in this way can we maintain competitiveness in the increasingly complex electronics market, ensure high-quality PCBA processing products, and meet the diverse needs of customers. Through continuous innovation and optimization, PCBA factories will be able to effectively cope with future mounting challenges.

-

Delivery Service

-

Payment Options