- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to evaluate the special material processing capabilities of PCBA factories?

2025-08-01

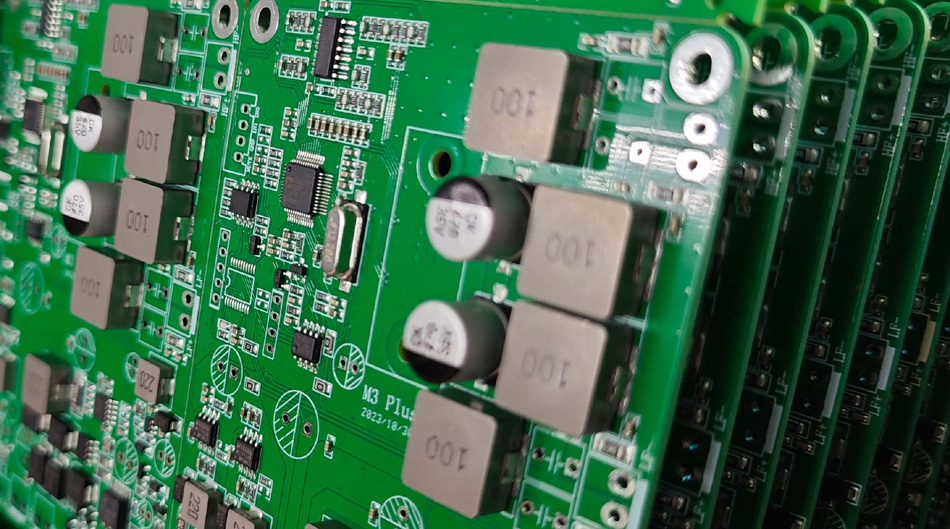

In the electronics manufacturing industry, the use of special materials is becoming increasingly common, such as high-frequency materials, thermal management materials, and flexible materials. These materials are often used in high-performance electronic products, requiring PCBA processing (Printed Circuit Board Assembly) to have high technical capabilities and processing levels. Therefore, evaluating the special material processing capabilities of PCBA factories is crucial to ensuring product quality and performance. This article will explore how to evaluate the capabilities of PCBA factories in special material processing.

1. Material properties and application understanding

Material properties

The properties of special materials directly affect their processing methods. For example, high-frequency materials usually have low dielectric constants and low loss factors, while thermal management materials require good thermal conductivity and high temperature resistance. When evaluating the special material processing capabilities of PCBA factories, you first need to have an in-depth understanding of the properties of the materials used in order to select the appropriate processing technology.

Application areas

Different special materials have different application areas in electronic products. Understanding the specific application of the material helps to evaluate whether the factory has the experience and ability to handle specific materials. For example, if the factory has successfully processed the materials required for high-frequency communication equipment, it may be more comfortable in processing similar materials.

2. Process capability assessment

Equipment capability

The equipment capability of the PCBA factory is an important factor in evaluating its special material processing capability. High-performance materials often require special equipment for processing, such as heat presses, laser cutters, or advanced printers. When evaluating, you should check whether the factory's equipment can meet the processing requirements of special materials, and understand the technical parameters and update frequency of the equipment.

Processing technology

Evaluate the factory's process capabilities in special material processing, including processes such as patching, soldering, cutting, and drilling. The processing of special materials often requires specific process parameters and processes. Ensuring that the factory has clear process specifications and corresponding quality control measures is an important indicator for judging its processing capabilities.

3. Quality control system

Quality standards

The processing of special materials requires a strict quality control system. Evaluate whether the quality control system of the PCBA factory meets international standards, such as ISO9001, IPC-A-610, etc. These standards ensure consistency and traceability during the processing process, which is crucial to ensuring the quality of the final product.

Testing capability

For finished products of special materials, the factory needs to have corresponding testing capabilities. Evaluating the factory's testing equipment and technology, such as dielectric performance testing, thermal conductivity testing, soldering strength testing, etc., can help determine its ability to monitor the quality of special material processing.

4. Technical support and R&D capabilities

Technical team

Evaluate the level of the PCBA factory's technical team, including the experience, professional background and knowledge reserves of engineers in special material processing. A high-level technical team can respond quickly to customer needs and provide effective solutions when encountering processing problems.

R&D capabilities

Evaluate the factory's R&D capabilities in special material processing, especially its exploration and application capabilities of new materials and new processes. Strong R&D capabilities can not only promote the advancement of processing technology, but also provide customers with more competitive product solutions.

5. Customer cases and feedback

Successful cases

Understanding the successful cases of PCBA factories in special material processing can help determine their true processing capabilities. Referencing the customer orders it has handled in the past, especially those involving complex materials or high-difficulty requirements, can provide a reliable basis for evaluation.

Customer feedback

Customer feedback and evaluation are also important aspects of evaluating the special material processing capabilities of PCBA factories. By communicating with existing customers and understanding the problems they encounter during processing and the factory's solutions, you can form a comprehensive understanding of the factory's service quality and technical level.

Conclusion

Evaluating the special material processing capabilities of PCBA factories is an important step to ensure the quality and performance of electronic products. By understanding material characteristics, evaluating process capabilities, reviewing quality control systems, examining technical support and R&D capabilities, and referring to customer cases and feedback, you can fully understand the factory's capabilities in special material processing. This not only helps to choose the right PCBA partner, but also lays the foundation for the success of the final product.

-

Delivery Service

-

Payment Options