- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does component procurement management of PCBA factories affect delivery time?

2025-07-24

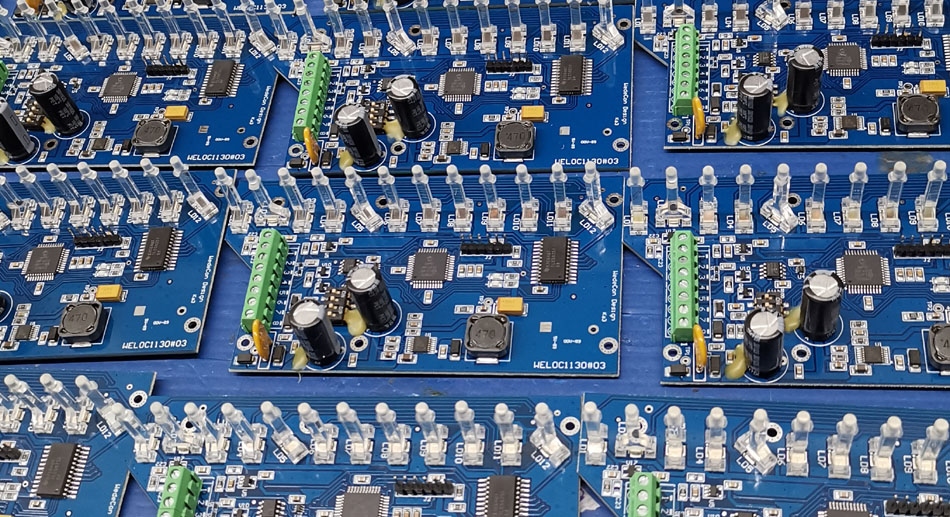

In the field of PCBA processing, component procurement management is one of the key factors affecting delivery time. Effective procurement management can not only ensure the smooth production process, but also significantly improve customer satisfaction and market competitiveness. This article will explore in depth how PCBA factories can shorten delivery time by optimizing component procurement management.

1. Supplier selection and management

1.1 Select high-quality suppliers

Selecting component suppliers with good reputation and stable supply capacity is the basis for ensuring timely supply. PCBA factories should select the most reliable partners by evaluating the supplier's historical delivery record and customer evaluation to ensure the timely supply of components.

1.2 Establish long-term cooperative relationships

Signing a long-term cooperation agreement with a supplier can not only lock in prices, but also improve the reliability of supply. In the contract, a regular supply plan can be agreed to ensure that a stable supply of materials can still be obtained during peak demand periods.

2. Procurement process optimization

2.1 Implement JIT (Just-in-Time) management

Implementing JIT management is an efficient supply chain management strategy. PCBA factories can accurately calculate the quantity and arrival time of required components according to production plans and actual needs. This management method helps to reduce inventory costs and reduce risks caused by excess or insufficient materials.

2.2 Dynamic procurement strategy

PCBA factories should flexibly adjust procurement strategies according to market changes and order conditions. When demand surges, the procurement volume can be increased in time, and when demand decreases, the procurement scale can be appropriately reduced. This dynamic procurement strategy can help factories cope with market uncertainties.

3. Inventory management and control

3.1 Accurate inventory forecasting

Through accurate demand forecasting and inventory management, PCBA factories can reduce inventory backlogs and related costs. With advanced inventory management systems, real-time monitoring of inventory levels and automatic replenishment can be achieved to ensure that production needs are met in a timely manner.

3.2 Regular inventory audits

Perform regular inventory audits to ensure the accuracy of inventory data. This helps to promptly identify and resolve problems in inventory, such as expired, damaged or excess components, thereby avoiding production delays.

4. Risk Management and Contingency Plan

4.1 Supplier Diversification

Establishing a diversified supplier network can reduce the risk caused by a single supplier problem. When the main supplier cannot deliver on time, the factory can quickly turn to other suppliers to ensure the continuity of production.

4.2 Emergency Procurement Strategy

Develop an emergency procurement strategy to deal with supply disruptions caused by emergencies. This includes establishing an emergency contact mechanism, a list of backup suppliers, and a rapid response process to ensure that quick action can be taken in an emergency.

5. Technology and Automation

5.1 Use Advanced Procurement Technology

Use advanced procurement technology and tools, such as supply chain management software and intelligent procurement platforms, to improve procurement efficiency and accuracy. These tools can help factories automate procurement processes, reduce human errors, and improve response speed.

5.2 Data-driven decision-making

By collecting and analyzing historical sales data, market trends, and customer feedback, PCBA factories are able to make accurate demand forecasts. This accurate forecast can help factories arrange production plans reasonably and reduce resource waste caused by insufficient or excessive inventory.

Conclusion

Component procurement management plays a vital role in the operation of PCBA factories. By optimizing supplier selection, procurement process, inventory management, risk management and adopting advanced technology, PCBA factories can significantly shorten delivery time, improve customer satisfaction and market competitiveness. In the ever-changing market environment, continuous innovation and improvement are the key to ensure the success of PCBA factories.

-

Delivery Service

-

Payment Options