- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are the core elements to ensure on-time delivery of PCBA factories?

2025-07-23

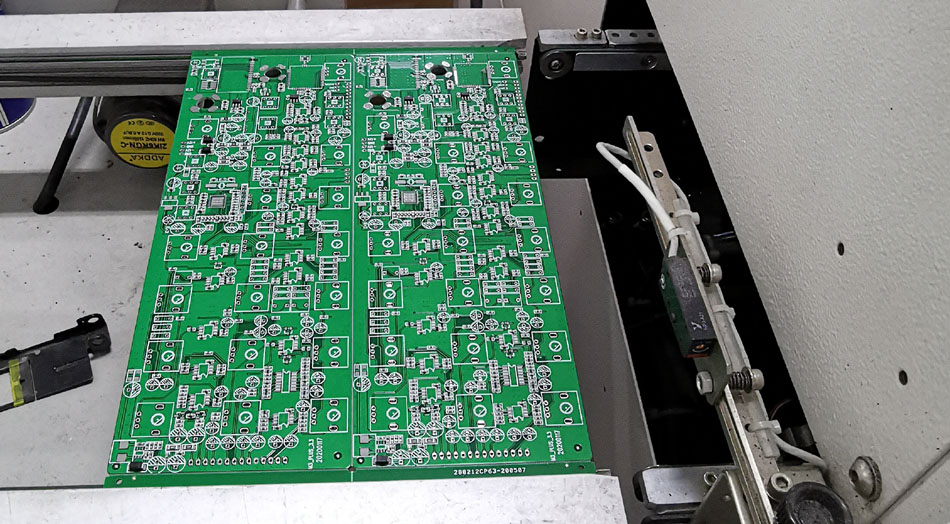

In the PCBA processing industry, on-time delivery is not only the basic expectation of customers for factories, but also the key ability of factories to stand out in the competition. The on-time delivery of PCBA processing depends not only on the efficiency of the production process, but also on production planning, resource management, quality control and other factors. This article will explore in depth the core elements to ensure on-time delivery of PCBA factories to help factories improve their delivery capabilities and win customer trust.

1. Reasonable production plan and progress control

Scientificity of production plan

In order to achieve on-time delivery, PCBA factories must have a scientific and reasonable production plan. The production plan should fully consider the order volume, delivery date, availability of production equipment and personnel arrangements to ensure that each batch of products can be advanced according to the time node.

Progress control and dynamic adjustment

Progress control in the production process is crucial. Using digital management tools such as ERP (Enterprise Resource Planning) system or MES (Manufacturing Execution System), real-time monitoring of the production process can be achieved. Once the progress is delayed, the factory can quickly adjust the production rhythm and allocate resources to ensure that the overall progress is not affected.

2. Equipment automation level and maintenance

Application of highly automated equipment

Automated equipment plays an important role in PCBA processing. For example, automated equipment such as placement machines and wave soldering machines can greatly improve production efficiency and reduce errors caused by human operation. Factories with higher automation levels are usually able to complete orders more efficiently, thereby ensuring on-time delivery.

Daily maintenance and care of equipment

Even with highly automated equipment, daily maintenance cannot be ignored. Regular maintenance can prevent equipment failures and improve the continuity and stability of production. Equipment that has not been regularly maintained may cause production stagnation when it fails, directly affecting delivery time. Therefore, factories need to establish detailed equipment maintenance and maintenance plans to ensure that the equipment is always in the best condition.

3. Stability of the material supply chain

Timeliness of the material supply chain

Materials in PCBA processing, including PCB boards, electronic components, solder, etc., are indispensable resources in the production process. Shortage of any material will affect the overall production progress. Therefore, factories need to establish a cooperative relationship with stable and reliable suppliers to ensure that materials arrive on time.

Inventory management of raw materials

To avoid production delays caused by material delays, factories can establish appropriate safety stocks based on historical order volumes and production needs. At the same time, monitor material inventory through a real-time inventory management system, purchase key materials in advance, and reduce the risk of delivery being affected.

4. Quality control system

Strict quality management process

Quality control in PCBA processing is not only related to product reliability, but also affects the continuity of production. A higher production qualification rate can reduce the number of reworks, thereby shortening the production cycle. Factories should establish a complete quality management system and use data analysis tools such as SPC (statistical process control) to ensure that the quality of each production link is qualified.

Inspection and feedback mechanism in the process

PCBA factories can set up inspection points in each production link to conduct comprehensive inspections and rapid feedback on products. For example, product defects can be detected through means such as automatic optical inspection (AOI) and online testing (ICT) to ensure that potential problems are discovered and resolved during the production process to avoid delivery delays.

5. Employee training and team management

Technical training for operators

PCBA processing has high technical requirements for operators, and skilled employees can complete production tasks faster and reduce mistakes. Therefore, the factory needs to conduct technical training regularly so that employees can master the latest processing technology and equipment operation specifications.

Coordination ability of the management team

The coordination ability of the management team directly affects the smooth completion of the order. An efficient management team can reasonably arrange production plans, coordinate human and material resources, and quickly respond to emergencies in the production process to ensure smooth production. The scientific coordination of the management team can effectively avoid problems such as production line congestion and material backlogs to ensure that orders are completed on time.

6. Smoothness of supply chain and customer communication

Transparent information communication

PCBA factories should maintain transparent information communication with customers and inform them of production progress and delivery expectations at any time. If abnormal situations occur during the production process and delivery may be delayed, the factory should communicate with customers in a timely manner to seek solutions to reduce the impact of delivery.

Emergency plan and resource allocation

In some urgent orders or emergencies, PCBA factories should have the ability to quickly allocate resources, such as overtime production or calling spare equipment. The perfection of the emergency plan is an important guarantee for the factory to handle emergencies and ensure on-time delivery.

Summary

The core elements to ensure on-time delivery of PCBA factories include scientific production planning, equipment automation and maintenance, stable material supply chain, perfect quality control system, professional quality of employees and coordination ability of management team. By continuously optimizing production processes, strengthening resource management and customer communication, PCBA factories can significantly improve the on-time delivery rate of orders, win customer trust and market competitive advantage.

-

Delivery Service

-

Payment Options