- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

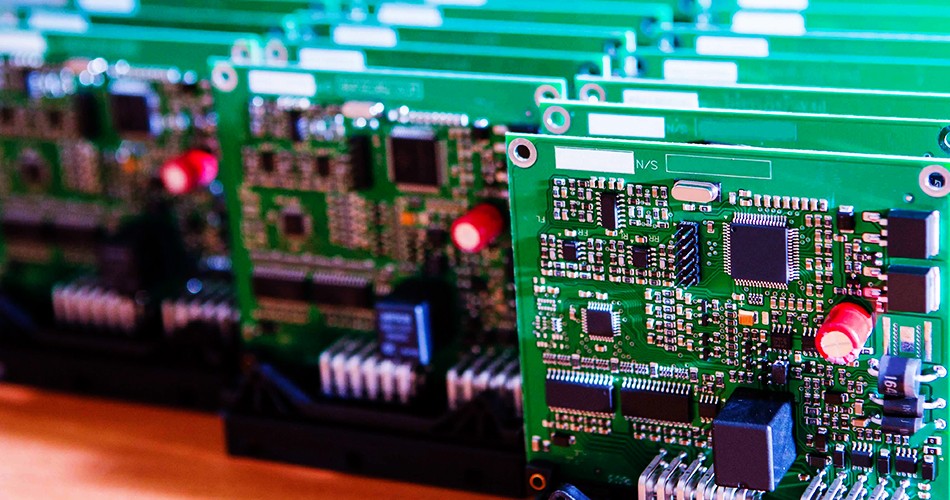

High rework rate in PCBA processing: how to reduce it?

2025-05-05

In the process of PCBA (Printed Circuit Board Assembly), high rework rate is an important issue that seriously affects production efficiency and cost. High rework rate not only increases production costs, but may also affect product delivery and customer satisfaction. This article will explore the main reasons for high rework rate in PCBA processing and provide effective strategies to reduce the rework rate.

I. Main reasons for high rework rate

1. Production process problems

soldering defects: Soldering is a key process step in PCBA processing. Poor soldering process may cause solder joints to be cold, short or open, which in turn leads to functional failure of the circuit board.

Poor patch: During the patch process, if the components are not placed accurately or the bonding is not firm, it will also cause problems in the circuit board during testing or use.

2. Raw material problems

Unqualified material quality: The quality of raw materials directly affects the quality of the final product. If unqualified components or PCB boards are used, it may lead to high rework rates.

Poor material management: Poor material management may lead to improper material storage, affecting the performance and reliability of the materials, and thus affecting production quality.

3. Equipment failure

Aging equipment: As the production equipment is used for a longer time, it may experience performance degradation or failure, affecting the processing quality. For example, inaccurate temperature control of soldering equipment may lead to poor soldering.

Inadequate equipment calibration: If the equipment is not calibrated regularly, it may cause processing errors and quality problems.

4. Operator problems

Irregular operation: If the operator does not strictly follow the process regulations, it may cause processing defects. For example, improper operation during soldering may cause solder joint problems.

Insufficient skills: Insufficient skill level and experience of operators may lead to inaccurate process control, thereby increasing the rework rate.

5. Inadequate testing and inspection

Incomplete testing: If the testing and inspection are not sufficient during the production process, defective products may not be discovered and handled in time, thus affecting product quality.

Unclear inspection standards: Unclear or lax inspection standards may cause products that do not meet quality requirements to flow into the next production link.

II. Effective strategies to reduce high rework rates

1. Optimize production processes

Improve soldering processes: Use advanced soldering techniques, such as wave soldering or reflow soldering, optimize soldering parameters, and ensure soldering quality. Regularly maintain and calibrate soldering equipment to keep equipment performance stable.

Improve patch accuracy: Use high-precision patch equipment and technology to ensure accurate placement of components. Regularly calibrate and maintain patch equipment to avoid poor patch performance.

2. Strictly control raw materials

Select high-quality materials: Purchase high-quality raw materials from reliable suppliers and conduct strict quality inspections on incoming materials to ensure that the materials meet specification requirements.

Improve material management: Establish a scientific material management system to ensure the correct storage and use of materials and avoid quality defects caused by material problems.

3. Strengthen equipment management

Regular maintenance and care: Develop equipment maintenance and care plans, regularly inspect and maintain production equipment to ensure normal operation of the equipment and reduce rework problems caused by equipment failures.

Equipment calibration: Calibrate equipment regularly to ensure processing accuracy and consistency. Calibration records should be complete to facilitate tracking of equipment status and performance.

4. Improve operator skills

Strengthen training: Regularly conduct technical training for operators to improve their operating skills and quality awareness. The training content should include process procedures, quality control and troubleshooting.

Implement standardized operations: Develop and implement standardized operating procedures to ensure that operators operate equipment in accordance with standards and reduce quality problems caused by human factors.

5. Improve testing and inspection

Comprehensive testing: Conduct comprehensive testing and inspection during the production process to promptly detect and handle defective products. The test items should cover all key parameters to ensure that the product meets quality requirements.

Clarify inspection standards: Develop clear inspection standards and processes to ensure the accuracy and reliability of inspection work. Inspectors should receive professional training to ensure that they have the necessary testing capabilities.

Conclusion

High rework rate is an important quality issue in PCBA processing, affecting production efficiency and customer satisfaction. By optimizing production processes, strictly controlling raw materials, strengthening equipment management, improving operator skills, and improving testing and inspection, companies can effectively reduce high rework rates and improve production quality and efficiency. In the face of future market competition, companies should continue to focus on best practices in quality management and continuously optimize production processes to meet customers' high standards.

-

Delivery Service

-

Payment Options