- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to handle changing customer needs and specifications in PCBA processing

2025-04-30

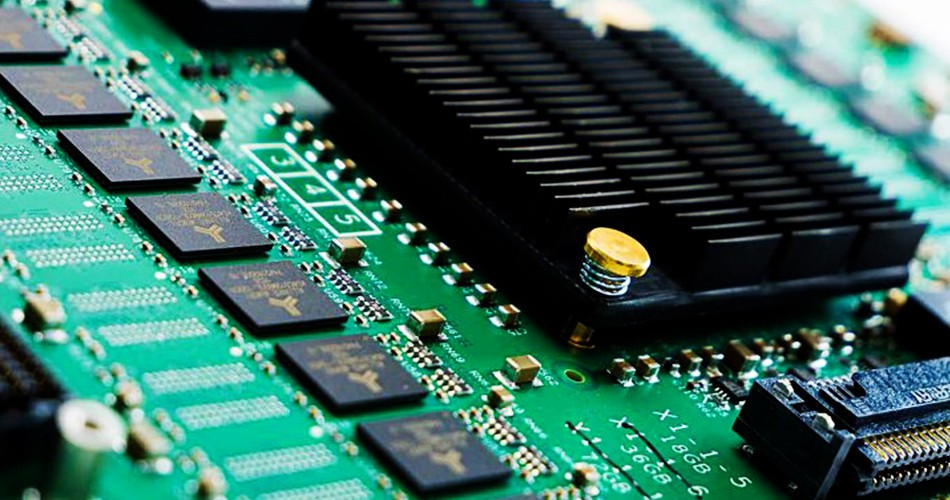

In the PCBA (Printed Circuit Board Assembly) processing process, the variability of customer needs and specifications is a common and challenging problem. Customer needs may change frequently due to market trends, technological advances or product upgrades, which requires companies to have the ability to adapt flexibly. This article will explore how to effectively handle these changing customer needs and specifications in PCBA processing and provide some practical strategies and methods.

I. Understanding and managing customer needs

1. Clarify the definition of needs

Detailed communication: Communicate with customers in detail to clarify needs and specifications. Ensure accurate understanding of customer needs through face-to-face communication, telephone conferences or email confirmation.

Requirement documents: Require customers to provide detailed requirement documents, including product specifications, design requirements and functional descriptions. The requirement documents can serve as the basis for project execution and reduce subsequent misunderstandings and changes.

2. Requirements change management

Change control process: Establish a requirement change control process to evaluate and manage the requirements changes proposed by customers. The change control process should include change application, evaluation, approval and implementation to ensure that changes can be effectively managed.

Change impact analysis: Conduct an impact analysis on each demand change to evaluate the impact of the change on production plans, costs and delivery dates. According to the results of the impact analysis, formulate corresponding adjustment measures.

II. Optimize production and supply chain management

1. Flexible production plan

Flexible production line: Design and use flexible production lines to adapt to different production needs and specifications. Flexible production lines can quickly adjust production processes and equipment configurations according to actual needs to improve production flexibility.

Dynamic adjustment: Dynamically adjust production plans according to changes in customer demand. Real-time monitoring of production progress and inventory to ensure rapid response to changes in demand.

2. Supply chain collaboration

Diversified suppliers: Cooperate with multiple suppliers to ensure that procurement strategies can be adjusted quickly when demand changes. Diversified suppliers can provide raw materials and components of different specifications to meet the diverse needs of customers.

Supply chain integration: Establish close cooperative relationships with all parties in the supply chain (such as suppliers and logistics companies) to achieve information sharing and collaboration. Supply chain integration can improve response speed and reduce delivery delays caused by supply chain problems.

III. Improve product design and development capabilities

1. Modular design

Design modularization: Use modular design methods to split products into multiple functional modules. Modular design allows products to be quickly adjusted between different specifications and functions, reducing the complexity of design changes.

Standardized components: Use standardized components and interfaces to improve the versatility and flexibility of design. Standardized components can reduce the complexity and change costs of design.

2. Rapid prototyping

Prototyping: During the product design phase, rapid prototyping is performed to verify the feasibility of the design and the degree to which it meets customer needs. Rapid prototyping can shorten the design cycle and reduce design risks.

Design verification: Use prototypes to verify the functions and performance of the design, and promptly discover and solve problems. The verification results can provide reliable data support for subsequent production.

IV. Improve customer communication and service

1. Real-time communication

Regular updates: Regularly provide customers with updated information on project progress to ensure that customers are aware of the latest status of the project. Regular updates can enhance customer trust and reduce concerns about progress.

Quick response: Quickly respond to customer inquiries and changes in requirements and provide timely solutions. Quick response can improve customer satisfaction and enhance customer willingness to cooperate.

2. Customer feedback mechanism

Establish feedback channels: Establish customer feedback channels to collect customer opinions and suggestions on products and services. Customer feedback can help companies understand customers' real needs and expectations and optimize products and services.

Feedback processing: Carefully handle and analyze customer feedback and promptly solve customer questions. Feedback processing results can serve as an important basis for improving products and services.

Conclusion

In PCBA processing, handling changing customer needs and specifications is the key to improving competitiveness and customer satisfaction. By understanding and managing customer needs, optimizing production and supply chain management, improving product design and development capabilities, and enhancing customer communication and services, companies can effectively respond to changes in demand and achieve efficient production and services. In the face of future market challenges, companies should continue to pay attention to changes in customer needs and continuously optimize and adjust strategies to maintain market competitiveness and customer satisfaction.

-

Delivery Service

-

Payment Options