- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

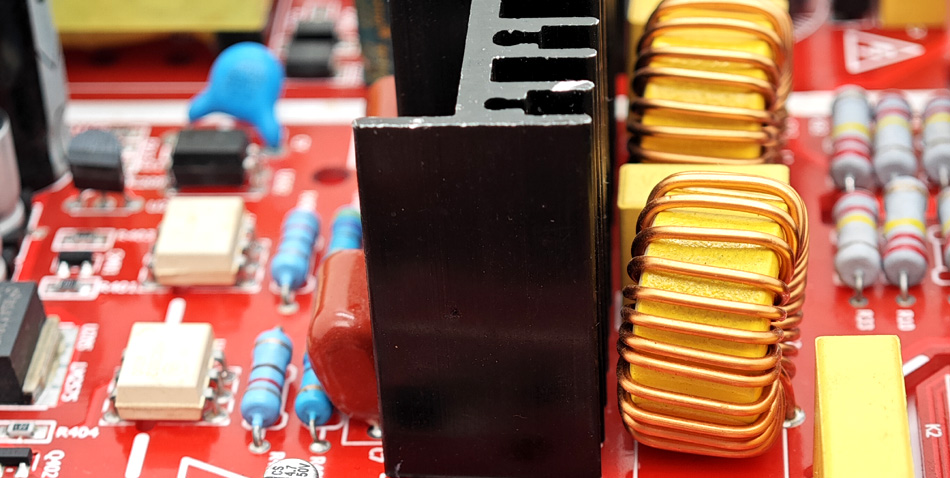

How to overcome the challenges of design changes in PCBA processing

2025-04-18

In the process of PCBA (Printed Circuit Board Assembly), design changes are an inevitable challenge. Design changes are often made to improve product performance, correct design defects or adapt to changes in market demand. However, frequent design changes may lead to production delays, increased costs and quality problems. Therefore, how to effectively respond to and overcome the challenges of design changes in PCBA processing has become an important issue for companies to maintain their competitiveness.

I. Challenges of design changes in PCBA processing

Design changes in PCBA processing usually trigger a series of chain reactions, including bill of materials (BOM) modifications, production process adjustments and increased difficulty in quality control. Specifically, the challenges brought by design changes are mainly reflected in the following aspects:

1. Production delays: After the design changes, the company needs to re-purchase new components and adjust the production line. This process may cause delays in production progress and affect the delivery cycle of the product.

2. Rising costs: Frequent design changes are often accompanied by additional procurement costs, production adjustment costs and waste disposal costs. These factors will directly lead to an increase in the overall cost of PCBA processing.

3. Quality risk: Design changes may introduce new quality issues, such as the compatibility of new components and the adaptability of production processes. If not handled properly, it may lead to a decline in product quality or even batch failure.

II. Strategies for dealing with PCBA processing design changes

In order to solve the challenges brought by design changes, PCBA processing companies can adopt a series of effective strategies to ensure smooth production and controllable costs.

1. Strengthen the design change management process: Establish a strict design change management process, including the evaluation, approval and execution of design changes. Companies should ensure that before design changes, they conduct a full feasibility analysis and evaluate the impact of changes on production, cost and quality to avoid unnecessary changes.

2. Improve communication efficiency with customers: Communicate with customers in a timely manner about the needs and possible impacts of design changes. Through efficient communication, misunderstandings and production delays caused by information asymmetry can be reduced, ensuring the smooth implementation of changes.

3. Flexibly adjust production plans: When facing design changes, companies should have the ability to flexibly adjust production plans. By optimizing production scheduling, giving priority to orders with less impact on the production line, the impact of changes on overall production can be reduced.

4. Strengthen supply chain management: Design changes often involve new material procurement. Enterprises should maintain close contact with suppliers to ensure the timely supply of key components. At the same time, you can consider establishing strategic reserves or looking for alternative suppliers to cope with sudden material needs.

5. Increase testing and verification efforts: After the design change, the company should increase the testing and verification of the new design to ensure the feasibility of the new design in actual production. Through strict quality control and testing, the quality risks brought by design changes can be effectively reduced.

Conclusion

Although the design change challenges in PCBA processing are complex, they are not insurmountable. By strengthening design change management, optimizing production plans, improving supply chain management, and increasing testing efforts, enterprises can effectively respond to various challenges brought by design changes, ensure smooth production and stability of product quality. In the future PCBA processing process, enterprises need to continuously improve their ability to respond to design changes to adapt to rapidly changing market demands and maintain competitive advantages.

-

Delivery Service

-

Payment Options