- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

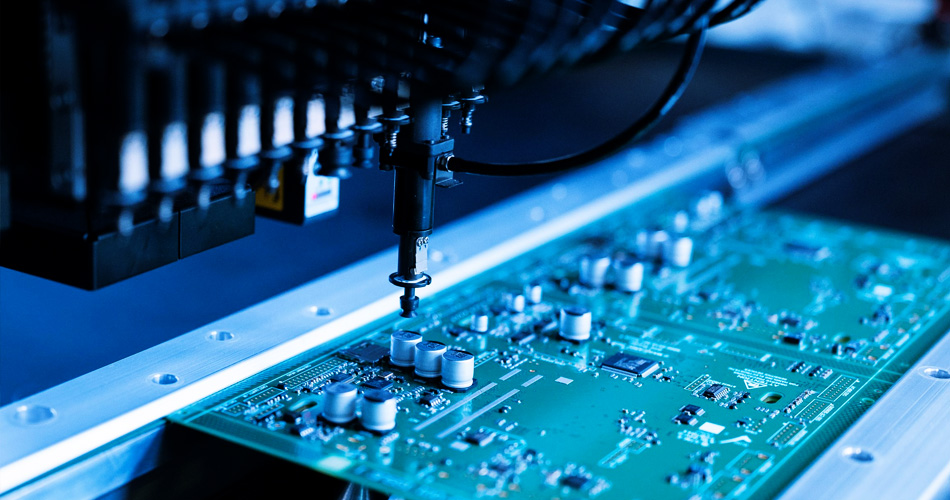

Common pain points and solutions in PCBA processing

2025-04-14

During the PCBA processing (Printed Circuit Board Assembly) process, manufacturers often face a series of challenges and pain points. If these problems are not solved, it will not only affect production efficiency, but also lead to product quality decline and even affect customer satisfaction. Therefore, it is crucial for PCBA processing companies to understand and effectively deal with these common pain points. This article will explore several common pain points in PCBA processing and provide corresponding solutions.

1. Quality control problems in the production process

Pain point analysis:

Quality control in PCBA processing is the core of ensuring product performance and reliability. However, due to the complexity of the production process, involving a variety of processes and equipment, quality control problems such as component misalignment, soldering defects, cold soldering or cold soldering are prone to occur in production. These problems not only affect the function of the final product, but also may lead to large-scale rework, increase costs and delivery cycles.

Solution strategy:

To solve the quality control problem, the application of automated inspection equipment, such as automatic optical inspection (AOI) and X-ray inspection (AXI), should be strengthened first. These devices can monitor product quality in real time during the production process, and detect and correct problems in time. In addition, establishing a strict quality management system, formulating detailed operating procedures and inspection standards, and conducting regular training for operators are also effective means to improve quality control.

2. Supply chain challenges in material management

Pain point analysis:

In PCBA processing, material management is a key link to ensure smooth production. However, due to the instability of the supply chain, material shortages or delivery delays often occur, which disrupts production plans and even affects the on-time delivery of orders.

Solution strategy:

In order to cope with supply chain challenges, companies should establish a diversified supply chain system to avoid dependence on a single supplier. In addition, the use of a digital supply chain management system can track the procurement, inventory and delivery of materials in real time, and warn of potential supply chain risks in advance. At the same time, establish long-term cooperative relationships with suppliers and ensure a stable supply of materials through strategic cooperation agreements.

3. Technical difficulties in soldering process

Pain point analysis:

The soldering process is one of the most critical steps in PCBA processing. With the high integration and miniaturization of electronic products, the complexity of the soldering process is also increasing. For example, small-pitch solder joints and double-sided board soldering have put forward higher requirements for soldering technology. If the soldering process is not properly controlled, it may lead to problems such as loose soldering and cold soldering, which seriously affect the performance and reliability of the product.

Solution strategy:

For the technical difficulties in the soldering process, the precision and stability of soldering can be improved by introducing advanced soldering technologies such as reflow soldering, wave soldering and selective soldering. At the same time, strengthen the temperature control during the soldering process to ensure that the soldering temperature curve meets the process requirements. Regular maintenance and calibration of soldering equipment to ensure that it operates in the best condition is also an important measure to ensure soldering quality.

4. Optimization of production efficiency and delivery cycle

Pain point analysis:

Competition in the PCBA processing industry is becoming increasingly fierce, and customers have higher and higher requirements for delivery cycles. However, problems such as inefficiency, equipment failure, and process bottlenecks in production often lead to production delays and failure to deliver products on time. This will not only affect customer satisfaction, but may also lead to the loss of orders.

Solution strategy:

To improve production efficiency and shorten delivery cycles, it is first necessary to conduct a comprehensive optimization analysis of the production process to identify and eliminate bottlenecks that affect efficiency. Implement Lean Manufacturing methods to reduce waste and optimize resource allocation. In addition, a flexible production line design is adopted to enhance the flexibility of the production system to cope with changes in different order requirements. At the same time, the equipment is regularly maintained to reduce the failure rate and ensure the continuity of production.

Conclusion

Although the common pain points in PCBA processing are diverse, these problems can be effectively solved through systematic strategies and continuous improvements. Enterprises should constantly sum up experience, optimize processes, and improve technical levels during the production process, so as to stand out in the fierce market competition. By solving the pain points in quality control, supply chain management, soldering technology and production efficiency, PCBA processing companies can not only improve production efficiency and product quality, but also improve customer satisfaction, and ultimately achieve sustainable development of the company.

-

Delivery Service

-

Payment Options