- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

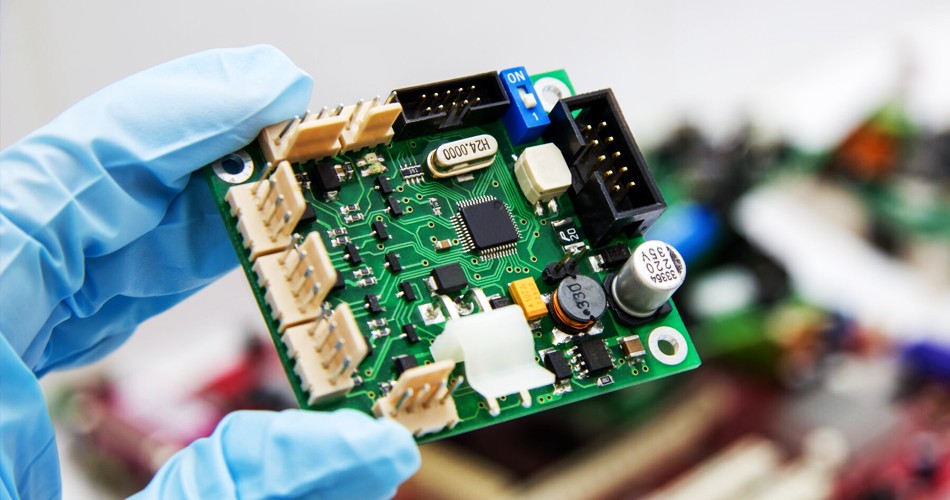

How to ensure that the quality of PCBA processing meets your product standards

2025-04-12

PCBA processing (Printed Circuit Board Assembly) is a key link in the production of modern electronic products. In order to ensure that your products are competitive in the market, quality control in PCBA processing is essential. This article will discuss in detail how to ensure that the quality of PCBA processing meets your product standards through effective measures.

1. Select high-quality raw materials and components

In the PCBA processing process, the selection of raw materials and components directly affects the quality of the final product. Therefore, it is crucial to ensure the procurement of high-quality PCB boards, electronic components and solders. When selecting suppliers, they should be subject to strict qualification review and their product quality should be evaluated regularly. In addition, suppliers can be required to provide necessary certification and test reports to ensure that the raw materials meet international standards.

2. Strict production process control

Every step of the PCBA processing process requires strict control. First, to ensure the accuracy and consistency of the soldering process, the use of advanced SMT (surface mount technology) equipment can improve the accuracy of component mounting. Secondly, during reflow soldering and wave soldering, the temperature curve needs to be controlled to avoid quality problems such as cold soldering or short circuits. Finally, after assembly, the PCBA board needs to be strictly cleaned to remove soldering residues to prevent affecting the electrical performance of the product.

3. Implement comprehensive quality inspection

Quality inspection is an important part of ensuring the quality of PCBA processing. Generally speaking, the inspection methods in PCBA processing include optical inspection (AOI), X-ray inspection (AXI), functional testing (FCT), etc. Optical inspection can quickly find problems such as misalignment and missing parts; X-ray inspection can check the quality inside the solder joint, such as bubbles, cold solder joints, etc.; and functional testing simulates actual use conditions to ensure that the PCBA board can work normally. Through these multi-level inspection methods, product quality can be ensured to the greatest extent.

4. Establish a complete quality management system

In order to systematically control the quality of PCBA processing, it is very necessary to establish and implement a quality management system of international standards such as ISO 9001. The system covers the whole process management from raw material procurement, production process control, to the final product delivery. Through continuous improvement and strict internal audits, quality risks can be effectively reduced. In addition, regular customer satisfaction surveys can also help companies to promptly discover and solve quality problems, thereby continuously improving the quality level of PCBA processing.

5. Maintain close communication with customers

Ensuring that the quality of PCBA processing meets product standards is inseparable from close communication with customers. During the processing process, timely understanding of customer needs and feedback, and making necessary adjustments to product design and processing technology are important means to ensure quality. In addition, regular project progress reports with customers to ensure information transparency and smooth communication can effectively avoid quality problems caused by information asymmetry.

Conclusion

In the fierce market competition, ensuring that the quality of PCBA processing meets product standards is the core task of every electronic manufacturing company. By selecting high-quality raw materials, strict production process control, comprehensive quality testing, establishing a sound quality management system, and maintaining close communication with customers, companies can improve customer satisfaction and market competitiveness while ensuring product quality. PCBA processing is not only a link in product production, but also an important guarantee for corporate brand and reputation.

-

Delivery Service

-

Payment Options