- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Data management and analysis in PCBA processing

2025-04-07

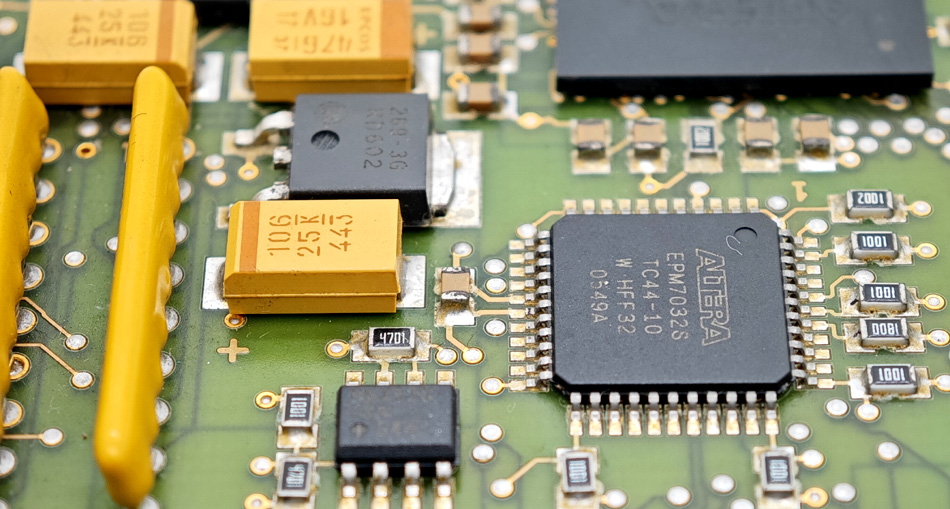

PCBA processing (Printed Circuit Board Assembly) is an important part of modern electronic product manufacturing. With the advancement of technology and the diversification of market demand, data management and analysis have become increasingly important in PCBA processing. Through effective data management and analysis, enterprises can optimize production processes and improve product quality and production efficiency. This article will discuss in detail the importance of data management and analysis in PCBA processing and how to implement it.

I. The importance of data management in PCBA processing

In the PCBA processing process, data management runs through the entire production chain, from raw material procurement, production planning, process parameters to final product testing, and each link involves a large amount of data. Good data management can bring the following advantages:

1. Improve production efficiency: Through data management, real-time monitoring and optimization of the production process can be achieved, reducing production stagnation and resource waste.

2. Improve product quality: Data management can help enterprises discover and solve quality problems in a timely manner and ensure that products meet quality standards.

3. Reduce production costs: Through data analysis, bottlenecks and waste in production can be identified and eliminated, reducing production costs.

4. Achieve traceability: Data management can record every link in the production process, realize full traceability of products, and facilitate the tracing and resolution of quality issues.

II. Key links in data management

In PCBA processing, data management involves multiple key links, mainly including:

1. Raw material management: record and manage the data of raw materials entering the factory to ensure the quality and timeliness of material supply.

2. Production plan management: formulate a reasonable production plan based on order requirements and production capacity, and monitor and adjust the execution of the plan.

3. Process parameter management: record and manage various process parameters used in the production process to ensure the stability and consistency of the process.

4. Quality inspection management: record and analyze data for each quality inspection link in the production process to ensure the controllability of product quality.

5. Equipment management: record and manage the operating status of production equipment to ensure the normal operation and maintenance of equipment.

III. Application of data analysis in PCBA processing

Data analysis is the core of data management. Through the analysis of production data, enterprises can obtain valuable information and insights, optimize production processes and improve product quality. Specific applications include:

1. Production optimization: Through the analysis of production data, bottlenecks and problems in production can be identified, production processes can be optimized, and production efficiency can be improved.

2. Quality improvement: Through the analysis of quality inspection data, the root causes of quality problems can be found, and effective improvement measures can be taken to improve product quality.

3. Cost control: Through the analysis of production cost data, waste in production can be identified and eliminated, and production costs can be reduced.

4. Predictive analysis: Through the analysis of historical data, future production needs and quality trends can be predicted, preparations can be made in advance, and production flexibility and adaptability can be improved.

IV. Implementation methods of data management and analysis

In PCBA processing, the following steps are required to achieve effective data management and analysis:

1. Data acquisition: Through automated equipment and sensors, various data in the production process are collected in real time to ensure the accuracy and timeliness of the data.

2. Data storage: Classify and store the collected data to ensure data security and traceability.

3. Data processing: Clean, organize and process the collected data to ensure data integrity and consistency.

4. Data analysis: Use data analysis tools and methods to analyze the processed data and extract valuable information and insights.

5. Data application: Apply the analysis results to production management, optimize the production process, and improve product quality and production efficiency.

Conclusion

Data management and analysis play an important role in PCBA processing, which can significantly improve production efficiency, improve product quality, reduce production costs and achieve traceability. Through effective data collection, storage, processing, analysis and application, enterprises can optimize production processes, solve problems in production and enhance market competitiveness. PCBA processing enterprises should actively adopt advanced data management and analysis technologies to realize the intelligence and refinement of production management and provide strong data support for the development of enterprises.

-

Delivery Service

-

Payment Options