- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Climate-Adaptive Design in PCBA Processing: How to Cope with Global Warming

2025-03-27

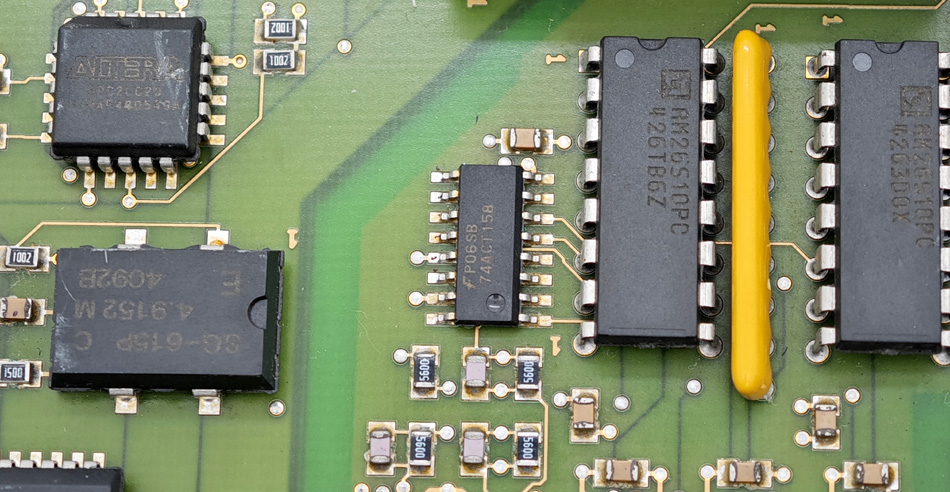

Global warming has had a profound impact on various industries, and the electronics manufacturing industry is no exception. In PCBA (Printed Circuit Board Assembly) processing, climate-adaptive design has become an important consideration. With extreme weather events and temperature fluctuations brought about by climate change, PCBA processing needs to be adjusted accordingly to ensure product reliability and performance. This article will explore how to implement climate-adaptive design in PCBA processing to cope with the challenges brought about by global warming.

I. The necessity of climate-adaptive design

1. Impact of global warming

Global warming has led to an increase in climate change and extreme weather events, including high temperatures, increased humidity, and frequent extreme climates. These changes pose challenges to the performance and stability of electronic products, especially in PCBA processing. High temperature and humidity may cause aging of electronic components, soldering defects, and material degradation, thus affecting the long-term reliability of the product.

2. Challenges in PCBA processing

In the PCBA process, high temperature and humidity changes brought about by climate change may cause defects in the soldering process, such as cold soldering and false soldering. In addition, thermal expansion and contraction in high temperature environments may also affect the structure and function of the circuit board. Therefore, climate-adaptive design is the key to ensure product quality and stability.

II. Climate-adaptive design strategy

1. Select high-temperature resistant materials

In PCBA processing, selecting high-temperature resistant materials can effectively cope with the high-temperature challenges brought about by global warming. The use of soldering materials and substrate materials with high thermal stability, such as high-temperature resistant epoxy resins and high-temperature alloys, can improve the stability and reliability of circuit boards in high-temperature environments. These materials are able to maintain their physical and chemical properties and ensure good soldering quality and electrical performance under extreme temperatures.

2. Enhance thermal management design

Enhancing thermal management design is an important strategy for coping with high-temperature environments. By optimizing heat dissipation design and adding heat sinks, the operating temperature of PCBA can be effectively reduced. For example, adding heat pipes or heat sinks to the circuit board, or designing a reasonable heat dissipation channel, can help dissipate heat more effectively and maintain stable operating temperatures.

3. Control humidity effects

High humidity environments may cause corrosion and material degradation of circuit boards. To meet this challenge, moisture-proof coatings and protective materials such as waterproof coatings and sealing materials can be used during PCBA processing. These protective measures can effectively isolate moisture and protect circuit boards and components from humidity, thereby improving the long-term reliability of products.

4. Conduct environmental testing

Conducting environmental testing is an important means to ensure that PCBA operates reliably under various climatic conditions. By simulating high temperature, high humidity and extreme weather conditions for testing, the performance of the product in actual use can be evaluated and potential design defects can be discovered. Environmental testing can help engineers optimize the design and improve the climate adaptability of the product.

5. Implement quality control

In PCBA processing, the implementation of strict quality control and monitoring systems can effectively respond to the challenges brought by climate change. By real-time monitoring of temperature and humidity during processing, potential problems can be discovered and adjusted in a timely manner to ensure that the production process and product quality remain stable. In addition, a sound quality management system is established to ensure that each link meets the requirements of climate adaptability design.

III. Prospects

1. Technological innovation

With the increasing severity of climate change issues, climate adaptability design in PCBA processing will continue to receive attention and development. The emergence of new materials and technologies will provide more solutions to help meet the challenges brought by global warming. For example, high-performance heat dissipation materials and improved moisture-proof technology will further enhance the climate adaptability of PCBA.

2. Industry standards

Industry standards and specifications will also be gradually strengthened, requiring PCBA processing companies to consider climate adaptability factors in design and production. Companies should pay close attention to the update of relevant standards and actively adjust the design and production processes to meet new requirements.

3. Environmental trends

With the improvement of environmental awareness, climate adaptability design in PCBA processing will also focus on sustainable development. By using environmentally friendly materials and optimizing production processes, companies can achieve environmental protection and energy saving goals while responding to climate change.

Conclusion

Global warming has brought many challenges to PCBA processing, including high temperature, increased humidity and extreme weather events. Through climate adaptability design, such as selecting high temperature resistant materials, enhancing thermal management design, controlling humidity effects, conducting environmental testing and implementing quality control, companies can effectively respond to these challenges and improve product reliability and stability. With the continuous development of technological innovation and industry standards, climate adaptability design will play an increasingly important role in PCBA processing, driving the industry towards higher environmental protection and sustainable development goals.

-

Delivery Service

-

Payment Options