- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

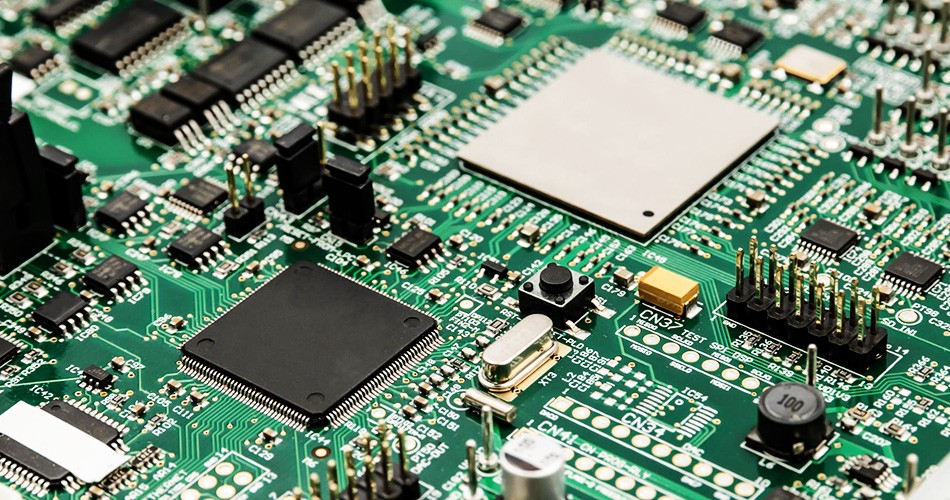

How to optimize PCBA design through user feedback

2025-03-26

In the PCBA (Printed Circuit Board Assembly) processing process, user feedback is an important basis for optimizing design and improving product quality. User feedback can not only help find problems in the design, but also provide directions for improvement. By effectively collecting and utilizing user feedback, companies can optimize PCBA design, improve product performance and user satisfaction. This article will explore how to optimize PCBA design through user feedback and provide implementation strategies.

I. Ways to collect user feedback

1. User surveys and questionnaires

Through user surveys and questionnaires, companies can systematically collect users' experience, performance requirements and improvement suggestions for PCBA products. These surveys can be conducted through online questionnaires, telephone interviews or face-to-face communication. When designing questionnaires, attention should be paid to all aspects of the product, including function, reliability, ease of use and appearance, in order to obtain comprehensive user feedback.

2. Product usage data analysis

Modern electronic devices are usually equipped with data collection functions that can record usage data in real time. By analyzing this data, companies can understand the actual usage of users and identify potential problems of products in actual use. For example, by monitoring the working status, failure frequency and usage environment of the equipment, deficiencies in the design can be found.

3. User support and after-sales service

The problems and needs encountered by users in the process of using the product are usually fed back to the company through support and after-sales service channels. Recording and analyzing these support requests and after-sales service records can help discover common problems in the design and provide a basis for improvement. Establishing an effective feedback tracking system can ensure that user problems are solved in a timely manner and collect valuable improvement suggestions.

II. Analyze and handle user feedback

1. Classification and prioritization

The collected user feedback usually involves multiple aspects, such as functional problems, performance deficiencies, and user experience. Classifying and prioritizing feedback can help companies focus resources on solving the most critical problems. For example, first deal with problems that affect the core functions of the product, and then solve improvement suggestions that have a greater impact on the user experience.

2. Cause analysis

When handling user feedback, it is crucial to conduct cause analysis. By deeply analyzing the problems mentioned in the user feedback, the root cause of the problem can be found. This may involve design defects, improper material selection, or production process problems. After finding the root cause, targeted optimization plans can be formulated to improve the reliability and performance of the design.

3. Develop an improvement plan

Developing a detailed improvement plan based on user feedback and cause analysis is the key to optimizing PCBA design. The improvement plan should include optimization goals, implementation steps, and expected results. With clear improvement goals and steps, the systematic and effective optimization process can be ensured. At the same time, a reasonable timetable should be set to ensure that improvement measures can be implemented in a timely manner.

III. Implementation of optimization and verification

1. Design optimization

Optimize the PCBA design based on user feedback and improvement plans. This may involve modifying the circuit layout, optimizing component selection, improving welding processes, etc. Design optimization should aim to improve product performance and user experience, and ensure that design improvements can solve practical problems.

2. Prototype testing and verification

After design optimization, prototype testing and verification are important steps to ensure the improvement effect. By making an optimized prototype and testing it under actual use conditions, the effectiveness of the improvement measures can be verified. Make necessary adjustments based on the test results to ensure that the final design can meet user needs.

3. Continuous feedback and improvement

Optimizing design is a continuous process. By establishing a continuous user feedback mechanism, companies can continuously collect user experience and suggestions and make timely design improvements. Continuous feedback and improvement can help companies maintain the competitiveness of their products and meet changing market demands.

Conclusion

Optimizing PCBA design through user feedback is an important strategy to improve product quality and user satisfaction. By effectively collecting user feedback, analyzing and handling feedback issues, formulating improvement plans and implementing optimization measures, companies can continuously improve product design, product performance and user experience. Establishing a continuous feedback mechanism and improvement process can ensure that PCBA design always meets user needs and enhances market competitiveness.

-

Delivery Service

-

Payment Options