- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Application and Challenges of 3D Printing Technology in PCBA Processing

2025-03-18

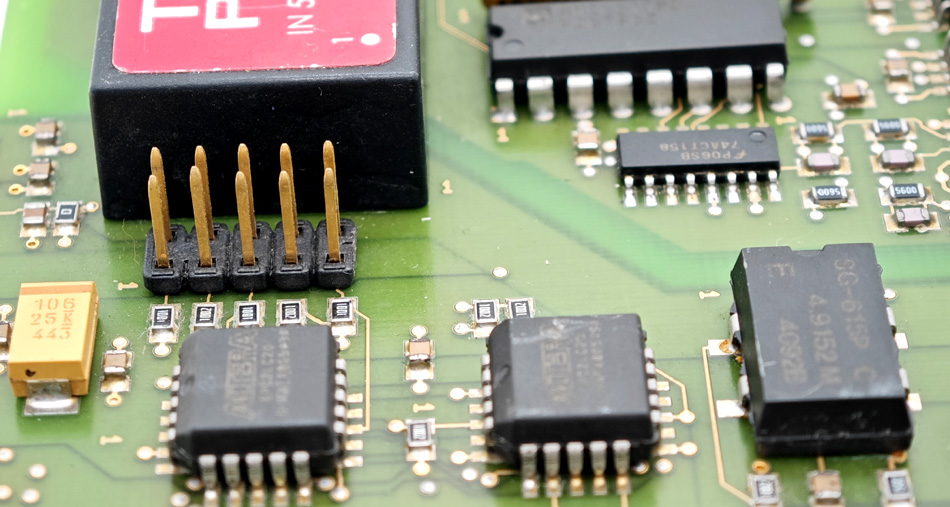

With the continuous advancement of science and technology, 3D printing technology has shown great potential in many fields. In PCBA (Printed Circuit Board Assembly) processing, the application of 3D printing technology has gradually attracted attention. This article will explore the application advantages and challenges of 3D printing technology in PCBA processing to help companies better understand and apply this emerging technology.

I. Application of 3D printing technology in PCBA processing

1. Rapid prototyping

A major application of 3D printing technology in PCBA processing is rapid prototyping. The traditional circuit board prototyping process usually takes a long time and is costly. Through 3D printing, circuit board prototypes can be quickly produced, helping engineers to conduct design verification and functional testing faster. This rapid feedback mechanism can accelerate the product development cycle and increase the speed of product launch.

2. Customized component production

3D printing technology allows customized production of complex components and structures according to needs. In PCBA processing, 3D printing can be used to manufacture some components with special shapes or complex structures to meet specific design requirements. This flexibility enables engineers to achieve a higher level of design innovation and product personalization.

3. Support complex geometric design

3D printing can produce complex geometric shapes that are difficult to achieve with traditional manufacturing methods. For complex circuit board designs and three-dimensional structures in PCBA processing, 3D printing technology can provide greater design freedom. Engineers can integrate more functions on the circuit board to improve the overall performance and application range of the circuit board.

II. Challenges

1. Material limitations

Although 3D printing technology has high flexibility, its material selection is still limited. In PCBA processing, circuit boards usually require specific conductive and insulating materials, and the material library of 3D printing technology cannot fully meet these needs at present. Although some emerging conductive and insulating materials have been developed, their performance and cost still need to be further improved.

2. Precision and consistency

3D printing technology still has certain challenges in high precision and consistency. For fine circuits and tiny solder joints in PCBA processing, 3D printing technology may find it difficult to achieve the same precision and consistency as traditional manufacturing methods. This may lead to reliability and performance issues in actual applications. Therefore, when applying 3D printing technology to PCBA processing, it is necessary to consider the impact of its precision on the quality of the final product.

3. Cost Issues

Although 3D printing technology can save time in the prototyping stage, its cost may be high in large-scale production. The purchase, maintenance and material costs of 3D printing equipment may affect the overall cost-effectiveness. Therefore, for the large-scale production of PCBA processing, how to balance the costs and benefits of 3D printing is an urgent problem to be solved.

4. Production Speed

Although 3D printing technology can quickly produce prototypes, its production speed is relatively slow. In the case of rapid production of large quantities of PCBA, the efficiency of traditional manufacturing methods is still relatively high. How to improve the production speed of 3D printing to meet the needs of large-scale production is a topic that needs further research.

3D printing technology has broad application prospects in PCBA processing, and can bring advantages such as rapid prototyping, customized component production and support for complex geometric designs. However, challenges such as material limitations, precision issues, cost and production speed still need to be overcome. With the continuous development of technology and the advancement of materials science, 3D printing is expected to play a greater role in PCBA processing and promote innovation and development in the industry. When applying 3D printing technology, companies need to consider these factors comprehensively to achieve optimal production efficiency and product quality.

-

Delivery Service

-

Payment Options