- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

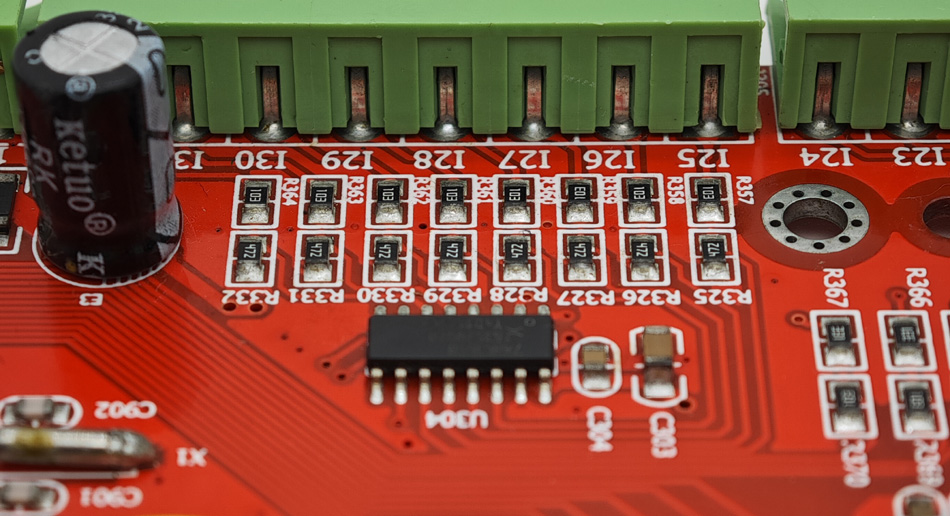

Quality Certification System in PCBA Processing

2025-03-17

In the process of PCBA (Printed Circuit Board Assembly), the quality certification system plays a vital role. Quality certification not only helps to ensure the consistency and reliability of products, but also improves customer trust and market competitiveness. This article will explore the main quality certification systems in PCBA processing, including its standards, certification process and its impact on production and enterprises, to help understand how to improve product quality and corporate image through quality certification.

I. Main quality certification standards

In PCBA processing, common quality certification standards include ISO 9001, IATF 16949, IPC standards and UL certification. These standards have different focuses and cover multiple aspects from management systems to specific processes.

1. ISO 9001:

Overview: ISO 9001 is a quality management system standard issued by the International Organization for Standardization (ISO) and is applicable to all types of organizations.

Requirements: Emphasize customer satisfaction, process management and continuous improvement. Enterprises are required to establish a comprehensive quality management system to ensure the consistency and reliability of products and services.

Application: Applicable to the overall quality management of PCBA processing enterprises, including supply chain management, production process control and customer service.

2. IATF 16949:

Overview: IATF 16949 is a quality management system standard for the automotive industry, which is a supplement and extension of ISO 9001.

Requirements: Special attention is paid to the special requirements of the automotive industry, such as product safety, zero defects and continuous improvement.

Application: For PCBA processing enterprises involving automotive electronic products, IATF 16949 certification can improve product quality and market competitiveness.

3. IPC Standards:

Overview: A series of electronic industry standards issued by IPC (Institute for Interconnecting and Packaging Electronic Circuits) cover all aspects from circuit board design to assembly and testing.

Requirements: Including IPC-A-610 (electronic component assembly standard), IPC-2221 (circuit board design standard), etc., providing detailed technical requirements and test standards.

Application: Guide the design, manufacturing and assembly processes in PCBA processing to ensure that products meet international standards.

4. UL Certification:

Overview: UL (Underwriters Laboratories) certification is a certification for product safety and performance, ensuring the safety of the product during use.

Requirements: Includes testing and certification of materials, electrical performance and environmental adaptability.

Application: For PCBA products that need to be sold on the market, UL certification can improve the market acceptance and reputation of the product.

II. Certification process

Obtaining quality certification requires a series of processes, including preparation, review and continuous improvement.

1. Preparation stage:

Establish a management system: Establish and improve the quality management system according to the requirements of the certification standards, including relevant processes and procedures.

Training and education: Train employees on the quality management system and certification standards to ensure that all personnel understand and can implement the relevant requirements.

2. Audit stage:

Internal audit: Conduct self-inspection to ensure that the management system meets the requirements of the certification standards, and identify and correct potential problems.

External audit: Invite the certification body to conduct a formal audit to verify whether the company meets the requirements of the certification standards. The audit process includes document inspection, on-site inspection and employee interviews.

3. Continuous improvement:

Tracking and evaluation: After obtaining certification, internal and external audits are conducted regularly to continuously track and evaluate the effectiveness of the quality management system.

Corrective measures: According to the audit results, corrective measures are formulated and implemented to continuously improve the quality management system and production process.

III. Impact on production and enterprises

Quality certification has a far-reaching impact on the production and business operations of PCBA processing companies.

1. Improve product quality:

Consistency and reliability: Through quality certification, companies can ensure the consistency and reliability of products and reduce defect rates and rework rates.

Customer satisfaction: High-quality products can improve customer satisfaction and trust and enhance market competitiveness.

2. Optimize the production process:

Process management: Quality certification requires companies to establish a sound production process management and control mechanism to optimize production efficiency and process flow.

Reduce waste: Through standardization and process improvement, reduce waste and resource consumption in production and improve production efficiency.

3. Improve corporate image:

Market recognition: Obtaining international certification can enhance the recognition of companies in the market and increase customer trust in corporate products.

Competitive advantage: Quality certification can bring competitive advantages to enterprises, especially in the international market, to meet the needs and expectations of different customers.

Conclusion

In PCBA processing, the quality certification system is an important tool to ensure product quality and enhance the competitiveness of enterprises. By understanding the main quality certification standards, the certification process, and the impact of certification on production and enterprises, enterprises can better implement quality management and improve the market recognition of products. Establishing and maintaining an effective quality management system can not only improve product quality, but also enhance the market position and customer trust of enterprises, laying a solid foundation for the long-term development of enterprises.

-

Delivery Service

-

Payment Options