- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Advanced soldering technology in PCBA processing

2025-03-07

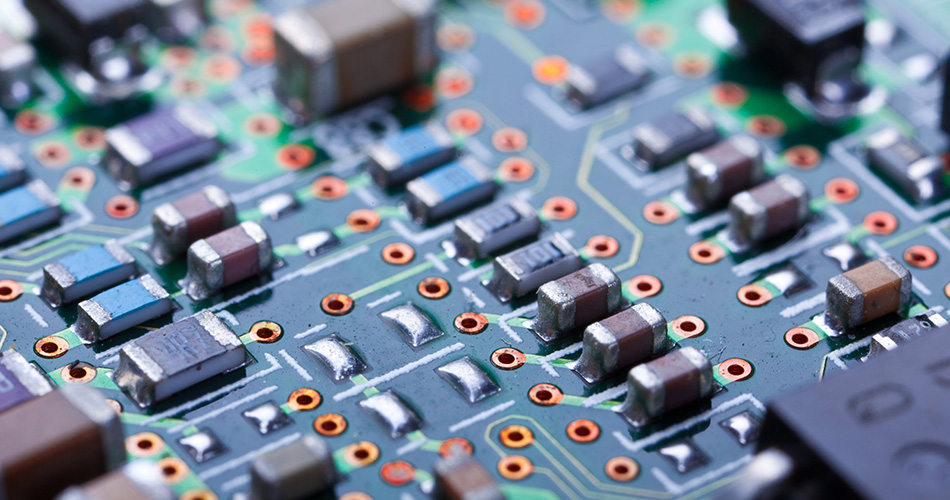

In PCBA (Printed Circuit Board Assembly) processing, soldering process is one of the key steps, and its quality directly affects the performance and reliability of the circuit board. With the continuous advancement of technology, many advanced soldering processes have been introduced into PCBA processing. These processes not only improve the soldering quality, but also improve production efficiency. This article will introduce several advanced soldering processes used in PCBA processing, including lead-free soldering, reflow soldering, wave soldering, and laser soldering.

I. Lead-free soldering technology

Lead-free soldering technology is one of the most important soldering processes in PCBA processing. Traditional soldering materials contain lead, which is a hazardous substance and has potential harm to the environment and health. In order to meet international environmental standards such as RoHS (Restriction of the Use of Certain Hazardous Substances Directive), many companies have turned to lead-free soldering technology.

Lead-free soldering mainly uses tin-silver-copper alloy (SAC), which is not only environmentally friendly, but also has excellent soldering performance. Lead-free soldering can effectively reduce the use of hazardous substances, improve soldering quality, and comply with strict environmental regulations.

II. Reflow soldering technology

Reflow soldering is a commonly used soldering process in PCBA processing, especially for circuit boards with surface mount technology (SMT). The basic principle of reflow soldering is to apply solder paste on the pads on the circuit board, and then melt the solder paste by heating to form a reliable solder joint.

1. Preheating stage: First, pass the circuit board through the preheating zone and gradually increase the temperature to avoid damage to the circuit board caused by sudden temperature rise.

2. Reflow stage: Entering the reflow zone, the solder paste melts, flows and forms solder joints at high temperature. Temperature control at this stage is crucial to the quality of soldering.

3. Cooling stage: Finally, the temperature is quickly reduced through the cooling zone to solidify the solder joint and form a stable soldering connection.

Reflow soldering technology has the advantages of high efficiency and high precision, and is suitable for large-scale production and high-density circuit boards.

III. Wave soldering technology

Wave soldering is a traditional soldering process for soldering plug-in components (THD). The basic principle of wave soldering is to pass the circuit board through a solder wave, and solder the pins of the plug-in components to the circuit board through the flow of solder.

1. Solder wave: There is a continuously flowing solder wave in the wave soldering machine. When the circuit board passes through the wave, the pins contact the pads and complete the soldering.

2. Preheating and soldering: Before entering the solder wave, the circuit board will pass through the preheating zone to ensure that the solder can melt and flow evenly.

3. Cooling: After soldering, the circuit board passes through the cooling zone, and the solder quickly solidifies to form a stable solder joint.

Wave soldering technology is suitable for mass production and has the advantages of fast soldering speed and high stability.

IV. Laser soldering technology

Laser soldering is an emerging soldering process that uses the high energy density of the laser beam to melt the soldering material to form a solder joint. This process is particularly suitable for high-precision, small-size and high-density PCBA processing.

1. Laser beam irradiation: The laser beam emitted by the laser soldering machine is concentrated on the soldering area to melt the solder material at high temperature.

2. Melting and solidification: The high temperature of the laser beam causes the solder material to melt rapidly and form solder joints under laser irradiation. Subsequently, the solder joints cool and solidify rapidly to form a reliable connection.

3. Precision and control: Laser soldering technology can achieve high-precision soldering and is suitable for micro components and complex soldering tasks.

Laser soldering technology has the advantages of high precision, high efficiency, and low thermal impact, but the equipment cost is high and it is suitable for high-end application scenarios.

Summary

In PCBA processing, advanced soldering processes such as lead-free soldering, reflow soldering, wave soldering and laser soldering can significantly improve soldering quality, production efficiency and environmental protection level. According to different production needs and product characteristics, enterprises can choose appropriate soldering technology to optimize the production process and improve product performance. By continuously applying and improving advanced soldering processes, enterprises can stand out in the fiercely competitive market and achieve higher production quality and efficiency.

-

Delivery Service

-

Payment Options