- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to improve product market competitiveness through PCBA processing

2025-03-06

In the fierce market competition, enterprises need to continuously improve the competitiveness of their products to gain market share. PCBA (Printed Circuit Board Assembly) processing is an important link in the production of electronic products, and its quality and efficiency directly affect the market performance of products. This article will explore how to improve the market competitiveness of products by optimizing PCBA processing, including improving product quality, shortening production cycle, reducing costs and enhancing product innovation.

I. Improve product quality

Improving product quality is the key to improving market competitiveness. High-quality PCBA processing can ensure the stability and reliability of electronic products and reduce the failure rate. To achieve high-quality processing, we can start from the following aspects:

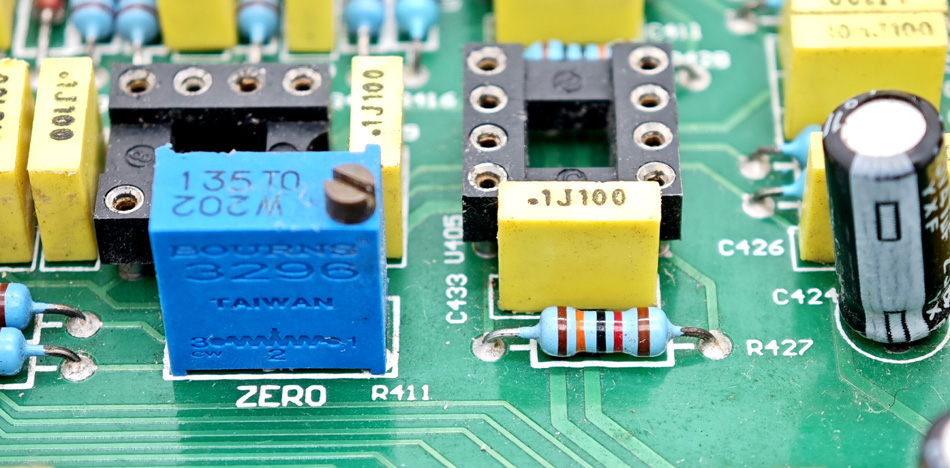

1. Use advanced production equipment: introduce high-precision placement machines, automated welding equipment and testing instruments to improve production accuracy and consistency.

2. Strict quality control: Establish a complete quality management system, from raw material incoming inspection to real-time monitoring during the production process, and then to the final product testing, to ensure that each link meets quality standards.

3. Lead-free soldering technology: Use environmentally friendly lead-free soldering materials that meet international environmental standards to improve the market acceptance of products.

II. Shorten the production cycle

In the market, fast product launch time often can gain competitive advantage. By optimizing PCBA processing, the production cycle can be effectively shortened:

1. Optimize the layout of the production line: Rationally arrange the workstations of the production line, reduce the material handling distance and production waiting time, and improve production efficiency.

2. Introduce automation technology: Use automation equipment, such as automatic placement machines and automatic welding machines, to reduce manual operation time and increase production speed.

3. Improve the flexibility of the production process: Adopt flexible production line design to quickly adapt to the production needs of different products and shorten production preparation time.

III. Reduce production costs

Reducing production costs is another important factor in improving market competitiveness. Optimizing PCBA processing can effectively control and reduce production costs:

1. Reduce material waste: By optimizing design and production processes, reduce the waste of raw materials and control production costs.

2. Improve production efficiency: By introducing automation equipment and optimizing production processes, improve production efficiency and reduce labor costs.

3. Procurement strategy: Select cost-effective raw material suppliers, establish long-term cooperative relationships with suppliers, and obtain more favorable procurement prices.

IV. Enhance product innovation

In the market, innovative products often stand out. PCBA processing can support product innovation in the following ways:

1. Support complex circuit design: Use advanced PCBA processing technology to support high-density and complex circuit design to achieve product multi-function and high performance.

2. Rapid prototyping: Through rapid prototyping technology, shorten the product development cycle and speed up the launch of innovative products.

3. Customized production: Provide personalized and customized PCBA processing services to meet the special needs of different customers and enhance the market appeal of products.

V. Improve product reliability and durability

Reliability and durability are important considerations for consumers when choosing electronic products. PCBA processing can improve product reliability and durability in the following ways:

1. High-standard inspection and testing: Use advanced inspection equipment such as automatic optical inspection (AOI) and electrical testing (ICT) to ensure that the product is defect-free during the production process.

2. Environmentally friendly technology: Use environmentally friendly materials and technologies, such as lead-free soldering and green chemicals, to improve product durability and meet international environmental standards.

3. Rigorous process flow: Optimize the production process to ensure that each process is strictly controlled to reduce the failure rate of the product.

Summary

By optimizing PCBA processing, companies can improve the market competitiveness of their products in many aspects. Improving product quality, shortening production cycles, reducing production costs, enhancing innovation, and improving reliability and durability are all important measures to enhance market competitiveness. Companies should use these strategies in combination to ensure the efficiency and high quality of the PCBA processing process, thereby gaining an advantage in market competition and winning more customers and market share.

-

Delivery Service

-

Payment Options