- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

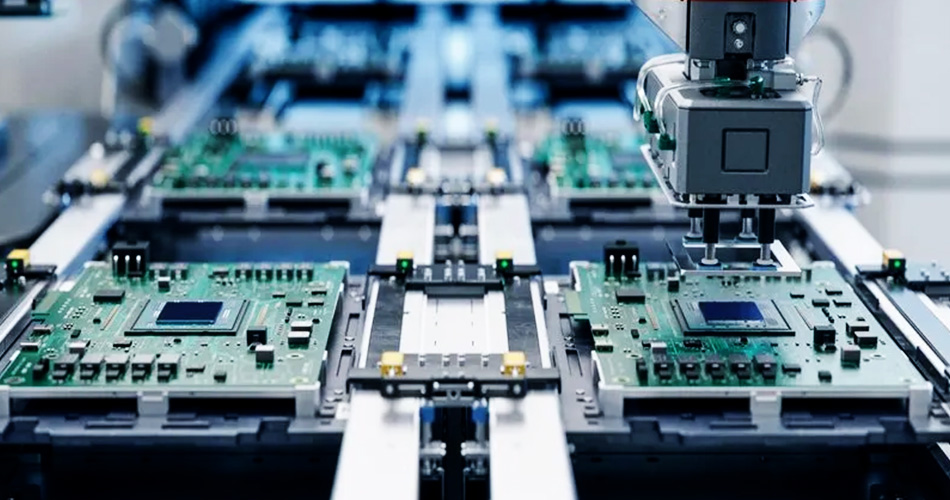

Selection of electronic components in PCBA processing

2025-02-03

In the process of PCBA processing (Printed Circuit Board Assembly), the selection of electronic components is crucial. Reasonable selection of electronic components can not only ensure the performance and reliability of the circuit, but also reduce costs and improve production efficiency. This article will discuss in detail the key factors and methods of selecting electronic components in PCBA processing.

I. Understanding design requirements

1. Functional requirements

When selecting electronic components, the functional requirements of the circuit must be clarified first.

Power management: Select appropriate power management components, such as regulators, converters, etc., to ensure the stability of the voltage and current of the circuit.

Signal processing: According to the signal processing requirements of the circuit, select appropriate amplifiers, filters and other components to ensure accurate signal processing.

2. Performance requirements

The performance requirements of the circuit are also an important basis for the selection of electronic components.

Frequency characteristics: High-frequency circuits need to select components with good high-frequency characteristics, such as high-frequency capacitors, high-frequency crystal oscillators, etc.

Temperature range: According to the working environment of the circuit, select components that adapt to different temperature ranges to ensure that the circuit can still work normally under extreme temperatures.

II. Consider the reliability of components

1. Quality and brand

Choose high-quality, well-known brand components to ensure their reliability and stability.

Well-known brands: Components from brands such as TI and ADI have a good reputation for quality and performance.

Reliability certification: Choose components that have passed relevant reliability certifications, such as ISO and RoHS certification, to ensure the quality of components.

2. Failure rate

Consider the failure rate of components and choose components with low failure rates to reduce the possibility of circuit failure.

MTBF (mean time between failures): Choose components with high MTBF to improve the overall reliability of the circuit.

Environmental adaptability: Choose components with strong adaptability that can work stably in harsh environments.

III. Optimize costs

1. Balance between price and performance

On the premise of ensuring performance and reliability, choose cost-effective components.

Cost control: Under the premise of meeting the circuit requirements, try to choose lower-priced components to reduce overall costs.

Performance priority: For critical circuits, performance and reliability are given priority, and even if the price is slightly higher, it is worth investing.

2. Bulk purchase

By purchasing in bulk, the purchase cost of a single component can be reduced.

Supplier cooperation: Establish long-term cooperative relationships with suppliers and strive for bulk purchase discounts.

Purchase plan: Develop a reasonable purchase plan to avoid high costs caused by emergency purchases.

IV. Compatibility and substitutability

1. Size and package

Select components with compatible size and package to ensure the flexibility and maintainability of circuit board design.

Standard package: Select components that meet standard packages, such as SMD and DIP packages, to facilitate production and maintenance.

Size consistency: Select components with consistent size to avoid design changes and assembly difficulties caused by size differences.

2. Substitutability

Select components with strong substitutability to ensure the stability of the supply chain.

Multiple suppliers: Select components provided by multiple suppliers to avoid out-of-stock caused by problems with a single supplier.

General components: Select general components commonly found in the market to facilitate procurement and inventory management.

V. Compliance with environmental requirements

1. Environmental certification

Select components that have passed environmental certification to ensure that the product meets environmental requirements.

RoHS certification: Select components that have passed RoHS certification to reduce the use of hazardous substances.

Lead-free soldering: Select components suitable for lead-free soldering to comply with environmental regulations.

2. Recyclability

Select components with strong recyclability to reduce environmental pollution.

Degradable materials: Give priority to components using degradable materials to reduce the impact of electronic waste on the environment.

Recycling: Select components that are easy to recycle to promote the sustainable use of resources.

Conclusion

In PCBA processing, the selection of electronic components is a key link to ensure product quality and performance. By understanding design requirements, considering component reliability, optimizing costs, focusing on compatibility and substitutability, and complying with environmental protection requirements, companies can achieve efficient and stable production in PCBA processing. Reasonable selection of electronic components can not only enhance the market competitiveness of products, but also promote the sustainable development of the electronics manufacturing industry.

-

Delivery Service

-

Payment Options