- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

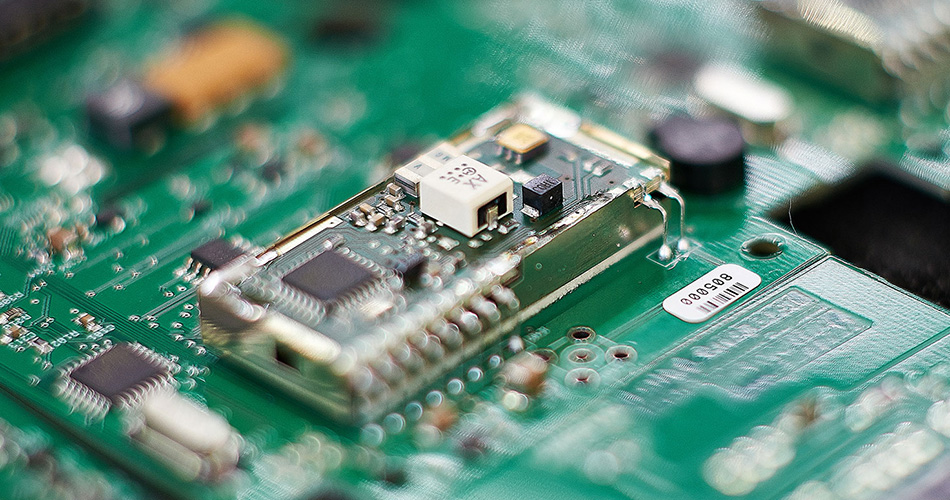

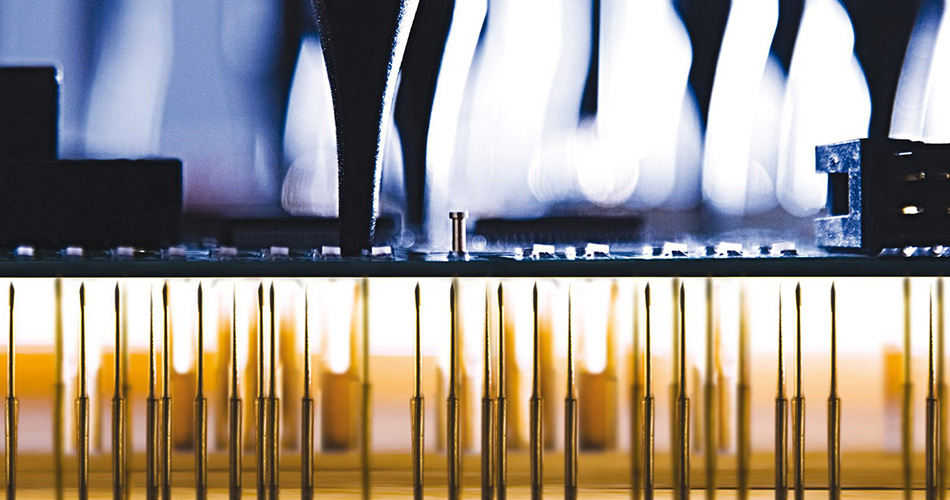

High-reliability soldering in PCBA processing

In the field of electronic manufacturing, PCBA processing (Printed Circuit Board Assembly) is a key link that directly affects the quality and reliability of electronic products. Among them, soldering is one of the most important processes in PCBA processing, and high-reliability soldering is the ke......

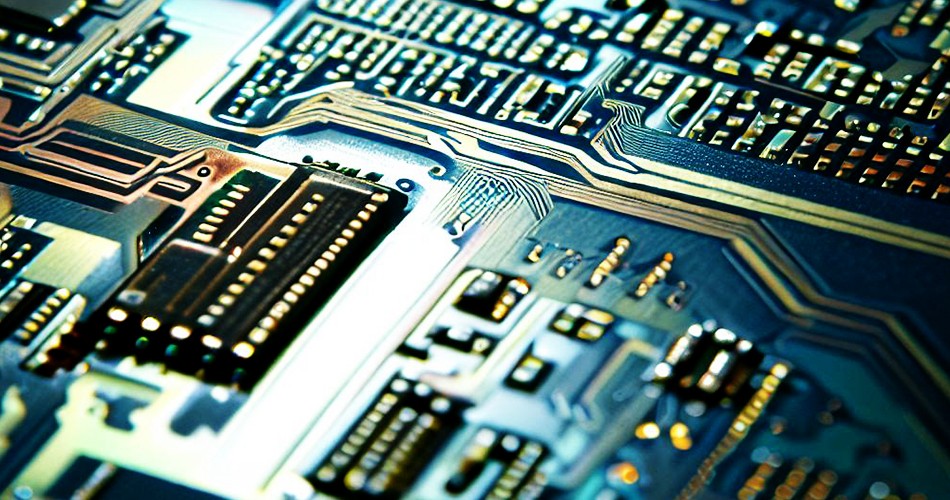

Read MoreElectromagnetic compatibility design in PCBA processing

Electromagnetic compatibility design in PCBA processing (Printed Circuit Board Assembly) is a crucial task, which is related to the stability, reliability and safety of electronic products. This article will explore the electromagnetic compatibility design in PCBA processing, introduce its concept, ......

Read MoreHalogen-free materials in PCBA processing

With the increasingly stringent environmental regulations and the improvement of people's awareness of environmental protection, halogen-free materials are increasingly widely used in PCBA processing (Printed Circuit Board Assembly). Halogen-free materials not only meet environmental protection requ......

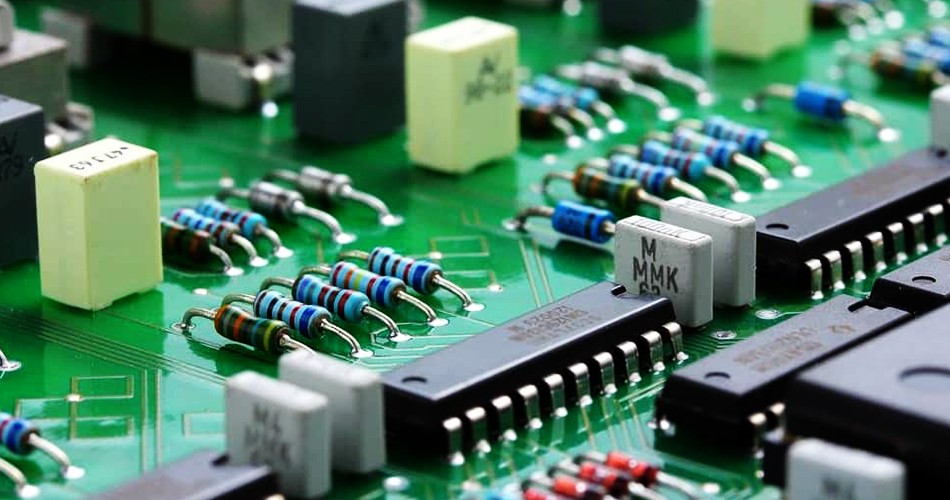

Read MoreSolderability coating in PCBA processing

PCBA processing (Printed Circuit Board Assembly) is one of the key links in the electronic manufacturing process. In PCBA processing, solderability coating is an important technology that directly affects the welding quality and the reliability of the circuit board. This article will explore the sol......

Read MoreHigh temperature solder in PCBA processing

In PCBA processing (Printed Circuit Board Assembly), high temperature solder is a key material that directly affects the welding quality and the reliability of the circuit board. This article will explore the high temperature solder in PCBA processing, introduce its role, types and advantages, and p......

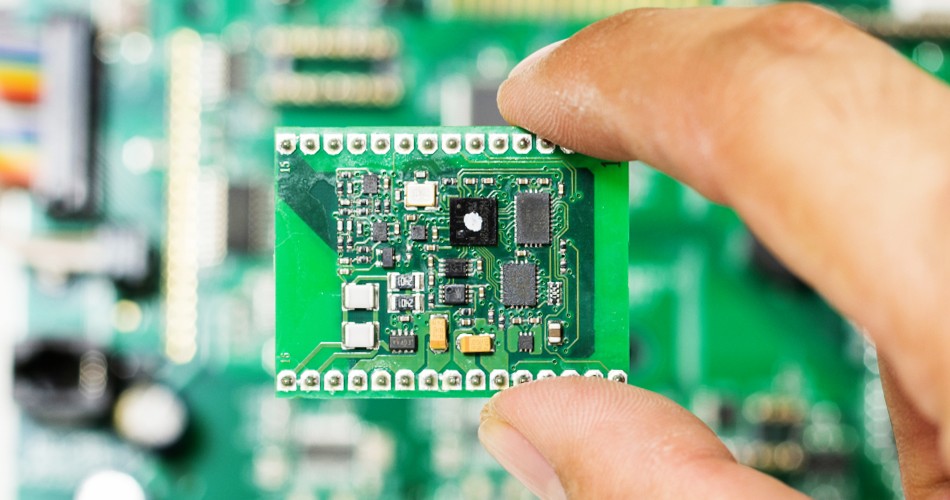

Read MoreAutomatic optical inspection in PCBA processing

PCBA processing (Printed Circuit Board Assembly) is a key link in the electronic manufacturing process. In this process, it is crucial to ensure the quality and reliability of the circuit board. As an advanced inspection technology, automatic optical inspection (AOI) plays an irreplaceable role in P......

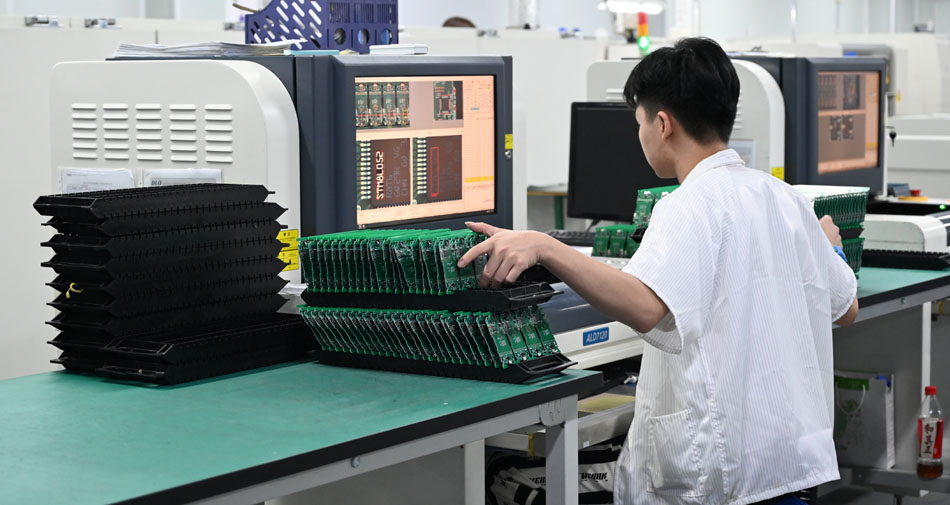

Read MoreIntelligent detection equipment in PCBA processing

With the continuous upgrading of electronic products and the increase in market demand, the complexity and precision requirements of PCBA (Printed Circuit Board Assembly) processing are getting higher and higher. In this context, the application of intelligent detection equipment in PCBA processing ......

Read MoreHigh frequency board design in PCBA processing

In modern electronic products, high-frequency circuit boards (High-Frequency PCB) are increasingly used in wireless communication equipment, radar systems and high-speed data transmission equipment. The design of high-frequency boards puts forward higher requirements for PCBA processing (Printed Cir......

Read More-

Delivery Service

-

Payment Options