- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

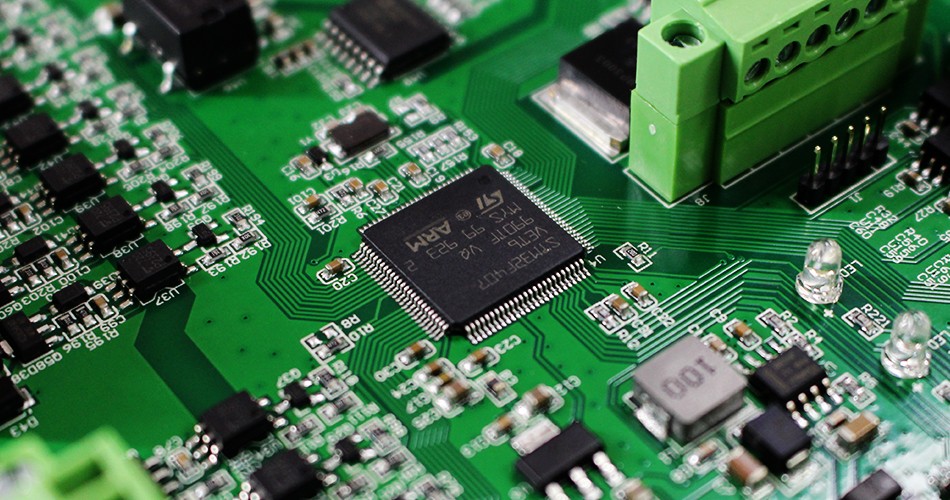

High-precision soldering in PCBA processing

High-precision soldering in PCBA processing (Printed Circuit Board Assembly) is an important part of ensuring the quality and performance of circuit boards. This article will explore high-precision soldering in PCBA processing in depth, including its definition, significance, common soldering techni......

Read MoreCleaning methods in PCBA processing

In the process of PCBA processing (Printed Circuit Board Assembly), cleaning is an important part of ensuring the quality and reliability of electronic products. This article will explore the cleaning methods in PCBA processing in depth, including its significance, common cleaning processes, importa......

Read MoreSoldering technology in PCBA processing

The soldering technology in PCBA processing (Printed Circuit Board Assembly) is one of the most important links in electronic manufacturing. This article will explore the soldering technology in PCBA processing in depth, including its significance, common soldering methods, importance and applicatio......

Read MoreEfficient management in PCBA processing

In the PCBA processing (Printed Circuit Board Assembly) industry, efficient management is the key to achieving high-quality production, cost control, and on-time delivery. This article will explore in depth the efficient management in PCBA processing, including its significance, importance, key elem......

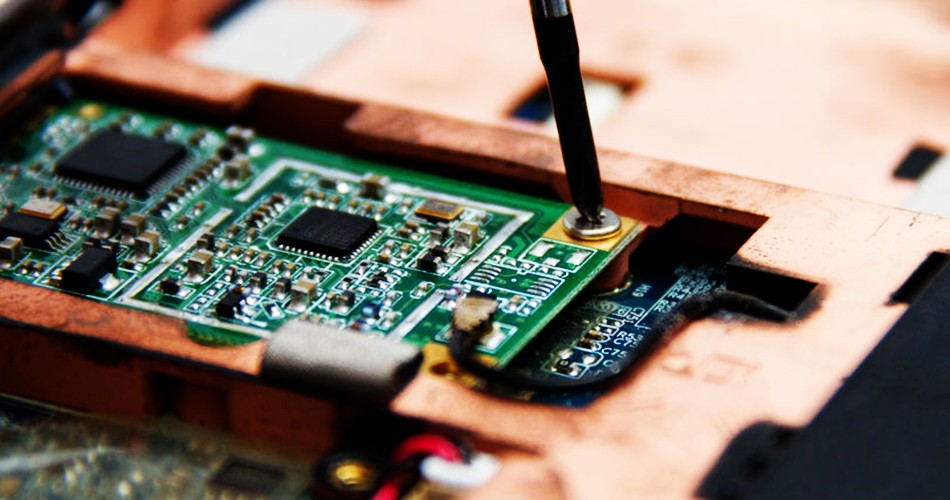

Read MoreComponent selection in PCBA processing

Component selection in PCBA processing (Printed Circuit Board Assembly) is one of the important factors affecting the performance and quality of electronic products. This article will explore the component selection in PCBA processing in depth, including its significance, common component types, sel......

Read MoreLead-free soldering in PCBA processing

Lead-free soldering technology in PCBA processing (Printed Circuit Board Assembly) has become an important trend in the development of the industry. This article will explore lead-free soldering in PCBA processing in depth, including its significance, advantages, application practices and developmen......

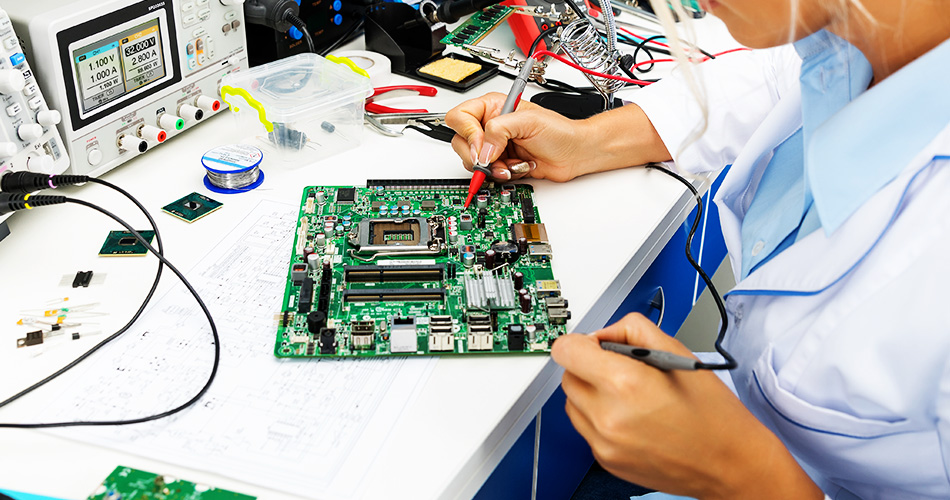

Read MoreElectrical testing in PCBA processing

In the process of PCBA processing (Printed Circuit Board Assembly), electrical testing is a key link to ensure the quality and performance of electronic products. This article will explore the electrical testing in PCBA processing in depth, including its significance, common testing methods, importa......

Read MoreIntelligent Manufacturing in PCBA Processing

With the continuous development and application of information technology, intelligent manufacturing has become a new trend and development direction in the field of PCBA processing (Printed Circuit Board Assembly). This article will explore intelligent manufacturing in PCBA processing in depth, inc......

Read More-

Delivery Service

-

Payment Options