- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Exploring Cooperation Models and Trends in Global PCBA Factories.

In the context of globalization, the PCBA (Printed Circuit Board Assembly) industry is undergoing a profound transformation. Increasingly diversified market demands and accelerating technological advancements are constantly changing the collaboration methods and operating models of global PCBA factories. Below, we examine several key trends.

1. Global Supply Chain Collaboration

Many PCBA factories are now utilizing multinational supply chains to optimize production. By integrating global raw materials and manufacturing resources, they can not only reduce costs but also improve production flexibility and responsiveness. For example, factories can source raw materials from different regions or distribute production tasks, making the process faster and more efficient.

2. Long-Term Partnerships

More and more companies are choosing to establish long-term partnerships with PCBA factories, ensuring stable supply and higher quality services. Long-term cooperation also allows both parties to jointly develop new products or technologies, enhancing market competitiveness, while enabling factories to better understand customer needs and provide customized solutions.

3. Technological Upgrades

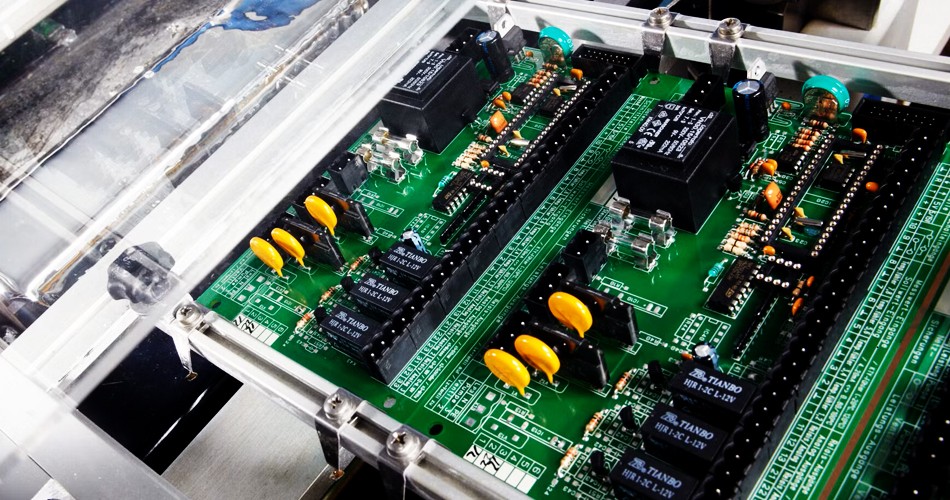

Modern PCBA factories are increasingly relying on automation, intelligent manufacturing, and data analysis to improve efficiency and quality. High-speed pick-and-place machines, automatic welding, and precision testing equipment significantly reduce human error and allow factories to respond quickly to customer needs and market changes.

4. Sustainable Development

Environmental protection and sustainable development are becoming increasingly important. PCBA factories and their customers are working together to promote green manufacturing, such as using environmentally friendly materials, reducing waste, and improving energy efficiency. This not only meets customer requirements but also enhances corporate image and reduces long-term costs.

5. Customer Customization Services

Customers are demanding increasingly personalized products, and PCBA factories are offering more customized services: flexible production schedules, rapid prototyping, and tailored designs. This not only increases customer satisfaction but also helps build long-term partnerships.

6. Quality Management and Risk Control

Quality and risk management are crucial for successful collaboration. Factories and customers need to ensure that every step of production meets standards, while also considering the risks of supply chain disruptions, technical failures, or market fluctuations. Addressing these issues ensures more reliable products and greater customer confidence.

7. Cross-Industry Collaboration

PCBA manufacturers are also exploring cross-industry collaborations: expanding into new markets in areas such as medical, automotive, smart home, and consumer electronics. This not only brings new opportunities but also drives technological innovation, allowing factories to find new growth points in diverse markets.

Brand Case Study: Global PCBA Collaboration in Practice

As a professional PCBA manufacturer founded in 2011, Unixplore Electronics has implemented these trends in the global PCBA industry:

Global Supply Chain Collaboration: Through multinational procurement and multi-line production management, Unixplore has an annual production capacity of over 1,500,000 PCBA boards and can provide 150,000 sets of complete machine assembly services, ensuring rapid delivery of customer orders.

Long-Term Strategic Partnerships: The company has established long-term cooperative relationships with customers in North America, Europe, and Asia, jointly developing smart home, medical equipment, and consumer electronics products.

Technological Upgrades and Intelligent Manufacturing: Equipped with 6 SMT production lines, 4 DIP lines, 2 finished product assembly lines, and various high and low-temperature testing chambers, achieving high-precision, high-efficiency, and high-reliability production.

Sustainable Development: Actively adopting environmentally friendly materials and energy-saving production solutions, promoting green manufacturing concepts, and winning praise from international customers.

Customized Services: Providing one-stop services such as rapid prototyping, functional testing, and firmware programming to meet the personalized needs of different customers.

Cross-Industry Expansion: Expanding from consumer electronics to medical, automotive, smart home, and other fields, achieving business diversification and technological innovation.

Through these practices, Unixplore not only guarantees product quality and delivery capabilities but also helps customers maintain competitiveness in the global market.

Send Inquiry

-

Delivery Service

-

Payment Options