- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

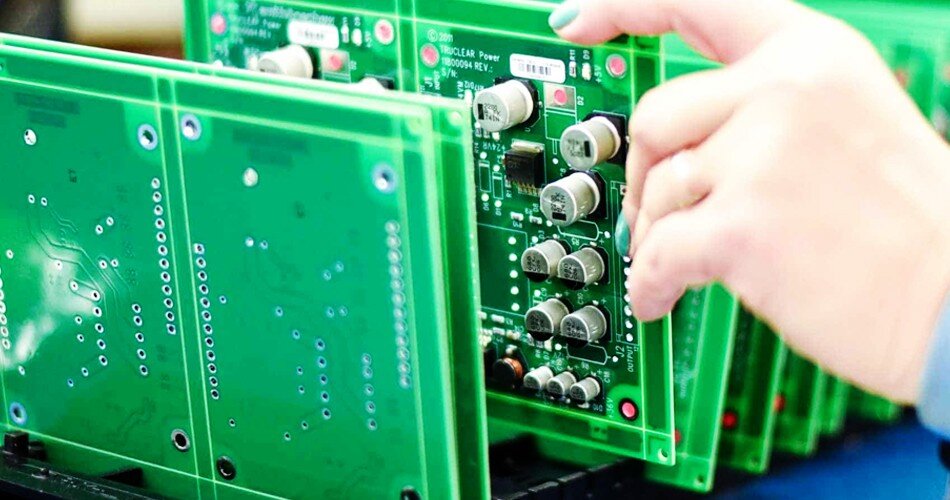

Why is Continuous Improvement Capability Crucial for PCBA Factories?

In the PCBA (Printed Circuit Board Assembly) industry, the ability to "continuously innovate and improve" directly determines whether a factory thrives or merely survives. In today's market, customer demands change daily, and technological advancements are happening at a breakneck pace. If we stick to old methods without adapting, we'll inevitably be left behind.

This article will frankly discuss why continuous improvement is so crucial for PCBA factories and how it helps improve efficiency.

Quick Response Prevents Being "Kicked Out" of the Market

The biggest challenge in the PCBA industry is "change." New products are released rapidly, and customers' demands for quality and delivery times are becoming increasingly stringent. The significance of continuous improvement is to make the factory more agile. Whether it's replacing old equipment or fine-tuning production line logic, as long as we can keep up with the customer's pace, we can retain orders. Simply put, higher efficiency and shorter delivery times naturally make customers more willing to place orders with you.

Quality is the Brand, Reliability is the Bottom Line

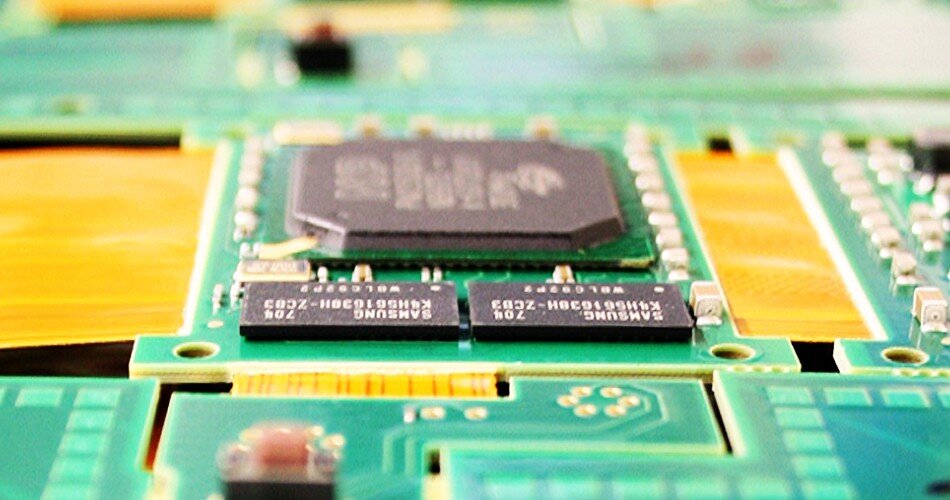

For board manufacturers, quality problems are a death knell. Continuous improvement helps us maintain strict quality control. This isn't a one-time effort, but a systemic approach: regular equipment "check-ups," meticulous quality control processes, and training for employees. Fewer defects, no returns, and a solid reputation mean customers will keep coming back.

Daring to Try New Technologies Leads to New Opportunities

In the PCBA industry, innovation is essential. Continuous improvement equips the factory with an "evolutionary engine." For example, implementing automated assembly and installing intelligent inspection equipment (AOI/SPI, etc.) might be a bit troublesome at first, but once everything runs smoothly, the production capacity and consistency will be far superior to manual labor. By staying ahead technologically, we can secure high-end orders that others can't handle.

A Strong and Motivated Team

Ultimately, the work is done by people. Continuous improvement shouldn't just rely on the boss's ideas; employees must be involved. Provide more training for workers, transforming them from "manual laborers" into "technical experts." When employees see their suggestions being adopted, they will feel more accomplished and be more likely to stay. A team that is dedicated and passionate is the factory's most crucial competitive advantage.

Even in a Highly Competitive Industry, We Can Stand Firm

The PCBA industry is currently extremely competitive. To avoid being overwhelmed, we must constantly stay ahead. By continuously optimizing processes, monitoring market trends, and learning from our competitors' strengths, we can create a significant gap in technology, cost, and service. Continuous improvement is essentially giving the factory a "booster shot," ensuring that we always have a winning hand in the ever-changing market.

Send Inquiry

-

Delivery Service

-

Payment Options