- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Accelerate Projects Through PCBA Factory Efficiency Improvements?

2025-12-17

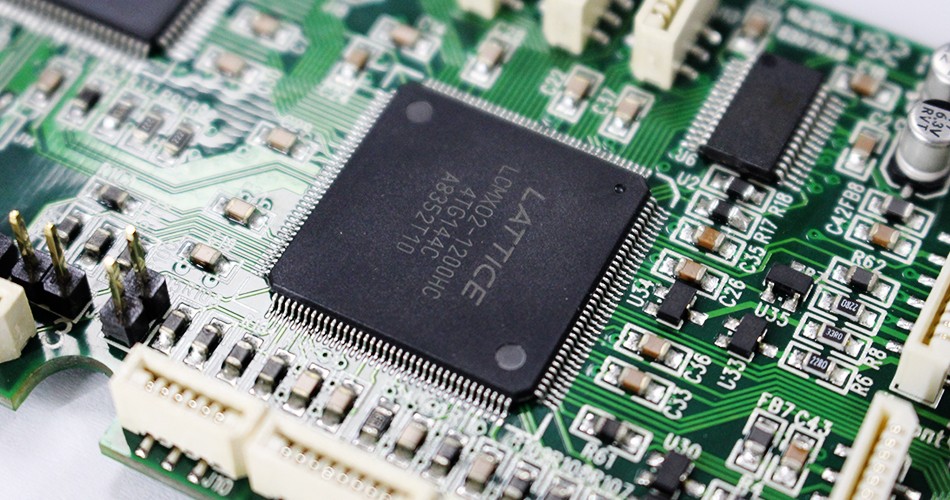

In the electronic air pump PCBA (Printed Circuit Board Assembly) manufacturing industry, project acceleration is paramount to keeping up with market demand and bringing products to market quickly. Finding an efficient PCBA factory can significantly improve overall project efficiency and accelerate project progress. This article will discuss how to advance projects by improving PCBA factory efficiency, and how these methods can help companies achieve their goals faster.

1. Optimizing Production Processes

Optimizing production processes is a core step for PCBA factories to accelerate project progress. Factories can start from these aspects: meticulously managing production lines, eliminating unnecessary operations, and improving the level of automated production. For example, using advanced SMT placement machines and fully automatic soldering furnaces will significantly improve speed and accuracy compared to older machines. However, hardware alone is not enough; it must be combined with lean manufacturing to eliminate wasted materials, unnecessary movements, and unnecessary waiting times. With powerful hardware and streamlined processes, production cycles are naturally shortened dramatically, and projects run as smoothly as if they were on steroids.

2. Implementing Efficient Supply Chain Management

Effective supply chain management is crucial for PCBA factories to accelerate projects. Factories must maintain good relationships with suppliers to ensure timely delivery of raw materials and components. Building a reliable supply chain network and optimizing procurement processes can shorten procurement time and reduce costs. Simultaneously, using inventory management systems to monitor inventory in real time prevents production stoppages due to material shortages. Efficient supply chain management not only improves efficiency but also ensures that projects stay on schedule.

3. Enhancing R&D and Design Capabilities

The R&D and design capabilities of a PCBA factory directly impact project efficiency. By improving R&D capabilities, factories can provide more efficient design services and shorten the design-to-production cycle. For example, using advanced CAD (Computer-Aided Design) software to optimize designs and using simulation testing to identify problems in advance. Addressing potential problems during the design phase reduces subsequent modifications and adjustments, allowing projects to proceed smoothly. Furthermore, continuously introducing new technologies allows for more innovative solutions during the design phase, further improving project execution efficiency.

4. Implementing Real-time Monitoring and Data Analysis

Real-time monitoring and data analysis act as the factory's command center. We can't just make decisions based on guesswork; we need to rely on data: after installing the monitoring system, it's immediately clear on the screen which SMT machine has broken down and which process is causing a bottleneck. By carefully analyzing this data, we can instantly identify where there's inefficiency or wasted time, and correct problems immediately, which is far better than waiting until production stops to try and fix things. By utilizing these idle equipment and time resources, the production line runs much faster, and project progress naturally surpasses that of our competitors!

5. Strengthening Team Training and Management

For a PCBA factory to succeed, relying solely on machines isn't enough; ultimately, it depends on the coordination of people and processes: through regular training, employees become skilled and versatile, eliminating basic errors at the source. Combined with effective team management that ensures smooth operation and responsiveness, materials, personnel, and production lines work together seamlessly like gears, leading to a significant increase in efficiency and progress.

-

Delivery Service

-

Payment Options