- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

High-Precision RCU PCBA Processing: Which Technological Innovations Have Changed Industry Standards?

2025-10-28

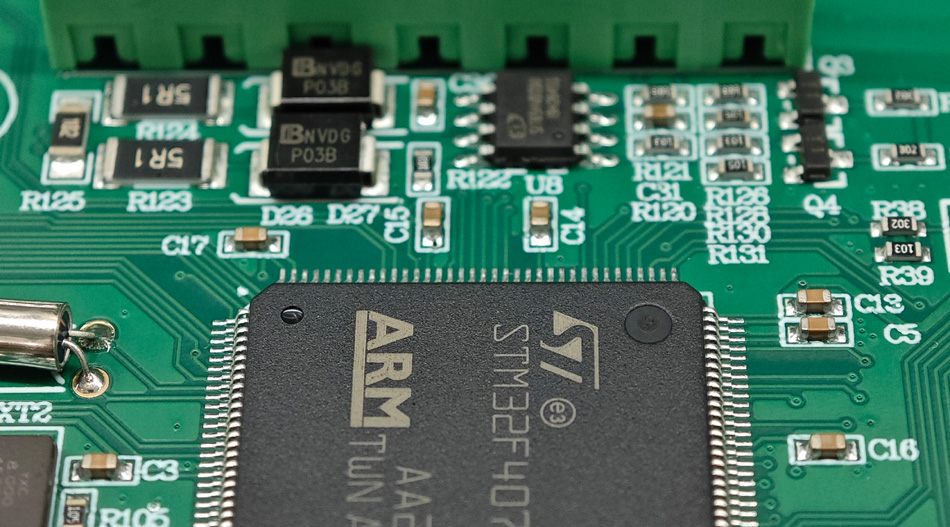

In the electronics industry, PCBA (Printed Circuit Board Assembly) processing is a critical step in ensuring product performance and reliability. With continuous technological advancements, high-precision RCU PCBA processing is becoming the new industry standard. This article will explore the technological innovations that have transformed the industry standard for PCBA processing.

1. The Rise of High-Precision Placement Technology

Precision Placement Machines

Modern RCU PCBA factories commonly use high-precision placement machines. These machines utilize laser alignment and vision systems to place components at the micron level. This technological advancement not only improves placement accuracy but also significantly reduces circuit failures caused by misalignment.

Multi-Function Placement Platforms

Multi-Function Placement Platforms allow simultaneous processing of components of varying sizes and types, greatly enhancing production flexibility. This technological innovation enables factories to quickly adapt to diverse market demands and meet customer requirements for personalized products.

2. Applications of Automation and Intelligence

Automated Production Lines

The introduction of automated production lines has significantly improved the efficiency and consistency of RCU PCBA processing. Integrated automated equipment significantly reduces manual intervention during the production process, thereby reducing the incidence of human error.

Intelligent Data Analysis

Intelligent data analysis tools monitor the production process in real time, collecting and analyzing production data. This data enables factories to identify problems and make adjustments promptly, thereby achieving higher production efficiency and product quality.

3. Advanced Inspection and Quality Control Technologies

Automated Optical Inspection (AOI)

Automated optical inspection technology has become a standard feature in RCU PCBA processing. AOI systems can quickly identify problems such as placement errors and solder defects, enabling early intervention during the production process. This technological innovation improves production reliability and ensures that the final product meets high-quality standards.

X-Ray Inspection Technology

X-Ray inspection technology is particularly suitable for inspecting high-density PCBs, effectively detecting defects hidden within the board. Through non-destructive testing, this technology ensures the reliability of complex circuit designs and enables high-precision PCBA processing.

4. Advances in Materials Science

New Substrate Materials

The development of new substrate materials enables RCU PCBA processing to withstand higher temperatures and pressures. These materials not only offer excellent electrical properties but also meet stricter environmental standards, promoting sustainable development across the industry.

Low-Temperature Soldering Technology

The application of low-temperature soldering technology reduces thermal damage to components and effectively reduces energy consumption during the production process. This technology is increasingly favored in high-precision PCBA processing, ensuring the reliability and durability of electronic products.

5. Flexible Production Management Model

Lean Production Concept

PCBA factories are increasingly adopting lean production concepts, improving production efficiency by optimizing production processes and resource allocation. This concept enables factories to reduce waste while increasing responsiveness and better meeting customer needs.

Customized Service

Providing personalized customer service is becoming a new trend in high-precision PCBA processing. Flexible production capabilities enable factories to quickly respond to customer needs and customize products to meet specific requirements.

Conclusion

Technological innovations in high-precision RCU PCBA processing are continuously driving industry standards. From high-precision placement technology and automated production lines to advanced testing and advances in materials science, these technologies not only improve production efficiency but also enhance product reliability. Faced with increasingly complex market demands, PCBA factories must keep pace with technological trends and continuously innovate to maintain a competitive advantage and meet customer expectations. In the future, with the further development of technology, high-precision PCBA processing will usher in greater opportunities and challenges.

-

Delivery Service

-

Payment Options