- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can PCBA factories meet the challenges of rush orders?

2025-10-25

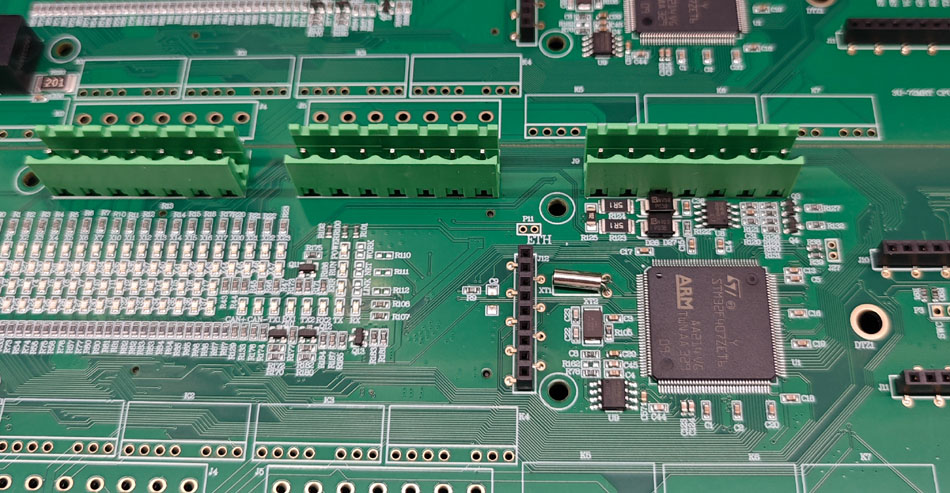

In the modern electronics industry, the flexibility and responsiveness of PCBA (Printed Circuit Board Assembly) processing directly impact a company's market competitiveness. Faced with increasing customer demand for urgent orders, PCBA factories must have effective response strategies to ensure timely delivery of high-quality products. This article will explore how PCBA factories can address the challenges of rush orders.

1. Improving Production Process Flexibility

Adopting Modular Production

PCBA factories can improve their flexibility in responding to rush orders by adopting a modular production process. This model allows factories to quickly adjust production lines based on order demand and flexibly allocate manpower and equipment resources. Modular production enables factories to complete the production of different products in a short period of time, meeting customers' urgent needs.

Implementing Intelligent Management

By introducing an intelligent management system, PCBA factories can monitor production progress and resource usage in real time. Such a system can quickly identify bottlenecks and optimize production scheduling, thereby improving overall production efficiency and ensuring that production plans can be adjusted swiftly in emergency situations.

2. Establishing Efficient Supply Chain Management

Optimizing Supplier Relationships

When facing rush orders, PCBA factories need to establish close partnerships with multiple suppliers to ensure a rapid supply of raw materials. Selecting suppliers with rapid response capabilities and maintaining long-term partnerships with them can help ensure timely material availability in emergency situations.

Implementing JIT (Just-in-Time) Supply

By implementing JIT supply management, PCBA factories can reduce inventory pressure while ensuring raw materials are available when needed. This strategy not only improves resource utilization but also effectively shortens delivery cycles.

3. Strengthening Teamwork and Communication

Improving Internal Collaboration Efficiency

Teamwork collaboration is crucial in the event of urgent orders. PCBA factories should strengthen internal communication to ensure real-time information sharing among various departments (such as procurement, production, and quality inspection). By establishing effective communication mechanisms, factories can respond quickly to customer needs and reduce production delays caused by information lags.

Training Multi-Skilled Employees

Having a multi-skilled workforce increases factory flexibility. In emergencies, employees can quickly switch roles as needed to fill manpower gaps. PCBA factories should regularly train their employees to enhance their comprehensive skills and adaptability to meet changing production demands.

4. Ensuring Quality Control

Rapid Quality Inspection Mechanisms

Ensuring product quality is equally important when responding to urgent orders. PCBA factories should establish a rapid quality inspection mechanism to ensure product quality inspections are completed within a short timeframe. By properly implementing quality inspection processes, factories can improve production efficiency without sacrificing quality.

Continuous Process Improvement

When handling urgent orders, factories should continuously improve their production and quality inspection processes. By collecting and analyzing data, they can identify issues affecting production efficiency and quality and develop appropriate solutions, thereby continuously enhancing their resilience.

5. Providing Customer Support and Feedback

Establishing a Prioritization Mechanism for Urgent Orders

PCBA factories can establish a mechanism for prioritizing urgent orders based on urgent customer needs. By communicating with customers and understanding their specific needs, factories can optimize production schedules and improve customer satisfaction.

Collecting Customer Feedback

After handling urgent orders, factories should promptly collect customer feedback to evaluate service quality and product performance. This feedback mechanism can help factories continuously optimize their response strategies and improve their ability to handle future urgent orders.

Conclusion

Facing the challenges of urgent orders, PCBA factories need to comprehensively improve production process flexibility, supply chain management, teamwork, quality control, and customer support. Through reasonable strategies and effective execution, factories can not only improve their ability to handle urgent orders, but also enhance customer trust and satisfaction. In the fierce market competition, improving the ability to handle urgent orders will win more opportunities and development space for PCBA factories.

-

Delivery Service

-

Payment Options