- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can PCBA factories ensure long-term product stability through after-sales service?

In the rapidly developing electronics manufacturing industry, PCBA (Printed Circuit Board Assembly) factories must not only provide high-quality products but also ensure their after-sales service systems are capable of guaranteeing long-term product stability. Excellent after-sales service helps customers resolve issues promptly, strengthens their trust in the product, and fosters long-term relationships. This article will explore how PCBA factories ensure long-term product stability through after-sales service.

1. Comprehensive After-Sales Service System

After-Sales Service Team

PCBA factories should establish a professional after-sales service team whose members possess extensive technical backgrounds and excellent communication skills. The after-sales service team is responsible for handling various customer inquiries and issues, ensuring prompt response to customer needs.

Standardized Service Processes

To improve service efficiency, PCBA factories should establish standardized after-sales service processes. These processes include problem reception, analysis, solution development, and customer feedback. Each step should be managed by a dedicated person to avoid delays caused by poor communication.

2. Efficient Problem Solving Mechanism

Real-Time Technical Support

PCBA manufacturers should provide real-time technical support to help customers quickly resolve issues they encounter during use. Whether it's product failure, technical inquiries, or operational guidance, the after-sales service team should be able to respond promptly to minimize customer downtime.

Quality Issue Handling

When quality issues arise, PCBA manufacturers need to establish an effective feedback and handling mechanism. The after-sales service team should be able to quickly investigate the cause and, based on the actual situation, propose solutions, including product replacement, repair, or technical guidance, to ensure continued normal use of the product.

3. Regular Maintenance and Inspection

Maintenance Plan Development

To ensure long-term product reliability, PCBA manufacturers can provide customers with regular maintenance plans. This includes regular equipment inspections and system upgrades to ensure that customers' equipment is always in optimal operating condition and reduce the risk of failure.

Technical Training and Support

PCBA manufacturers should also provide customers with regular technical training to help them understand product usage and maintenance techniques. This training not only improves customer efficiency but also enables them to conduct preliminary troubleshooting on their own when problems arise.

4. Customer Feedback Mechanism

Collecting Customer Feedback

PCBA factories should establish a comprehensive customer feedback mechanism to regularly collect customer feedback and suggestions on their products and services. This feedback can help factories promptly identify potential product issues and customer needs, allowing them to implement targeted improvements.

Feedback Analysis and Improvement

By analyzing customer feedback, PCBA factories can optimize product design and service processes. This continuous improvement mechanism not only improves product quality but also enhances customer satisfaction and loyalty.

5. Continuous Technological Innovation

Investing in R&D

PCBA factories should continuously invest in R&D to adapt to market changes and increasing customer demands. Through technological innovation, factories can launch products with higher performance and reliability, providing customers with a more stable user experience.

Applying New Technologies

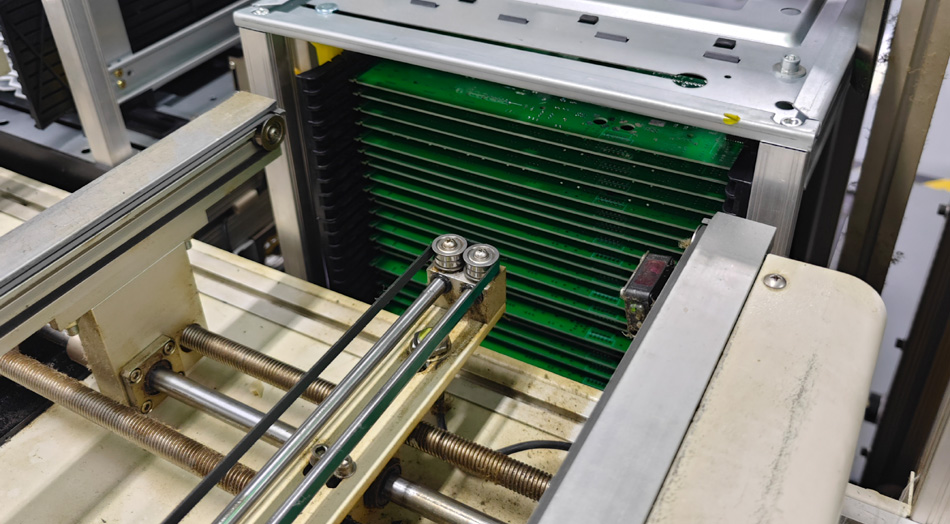

With the continuous advancement of industry technology, PCBA factories should actively introduce new technologies, such as automated production and intelligent monitoring. The application of these new technologies can improve product production efficiency and stability, fundamentally reducing failure rates.

Conclusion

PCBA factory after-sales service plays a vital role in ensuring the long-term stability of products. By establishing a comprehensive after-sales service system, efficient problem-solving mechanisms, regular maintenance and inspections, customer feedback mechanisms, and continuous technological innovation, PCBA factories can effectively improve customer satisfaction and product reliability. Only by continuously pursuing excellence in after-sales service can factories remain invincible in the fierce market competition.

Send Inquiry

-

Delivery Service

-

Payment Options